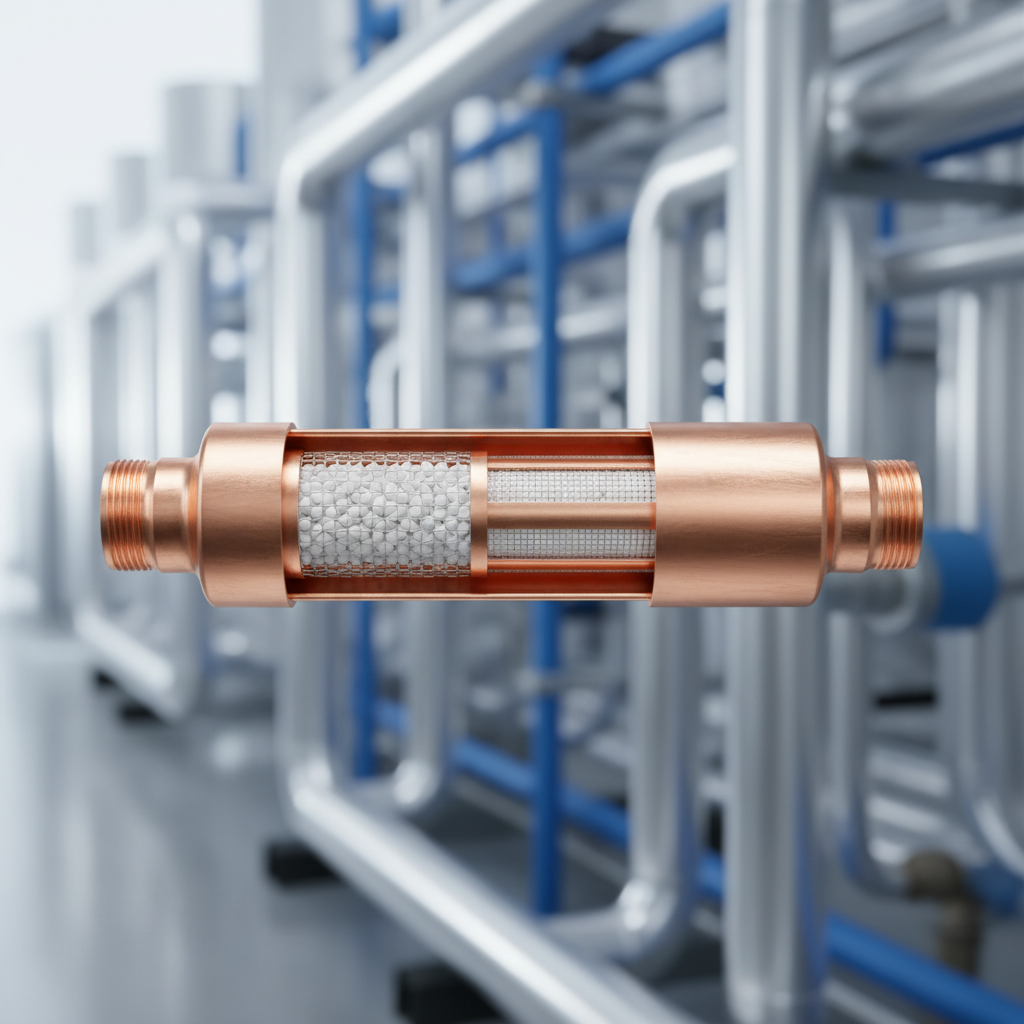

In the evolving landscape of HVAC systems, the selection of components can significantly impact efficiency and performance. A critical yet often overlooked component is the Copper Filter Drier, which plays a vital role in maintaining the integrity of cooling and refrigeration systems. Industry reports indicate that approximately 30% of HVAC failures can be traced back to inadequate filtration and moisture control, emphasizing the importance of choosing the right filter drier.

As we approach 2025, the demand for high-efficiency HVAC systems continues to rise, driven by stringent regulations and a growing emphasis on sustainable practices. The copper filter drier not only enhances system reliability by filtering out impurities but also serves as a crucial safeguard against moisture, which is a known enemy to refrigerants and can lead to system failures. Research has shown that systems equipped with quality filter driers can improve overall performance by up to 15%, resulting in reduced energy consumption and lower operational costs.

This guide aims to provide a comprehensive overview of the criteria necessary for selecting the optimal copper filter drier for your specific HVAC needs. By understanding the unique characteristics and applications of various filter driers, HVAC professionals and consumers alike can make informed decisions that contribute to the longevity and efficiency of their systems.

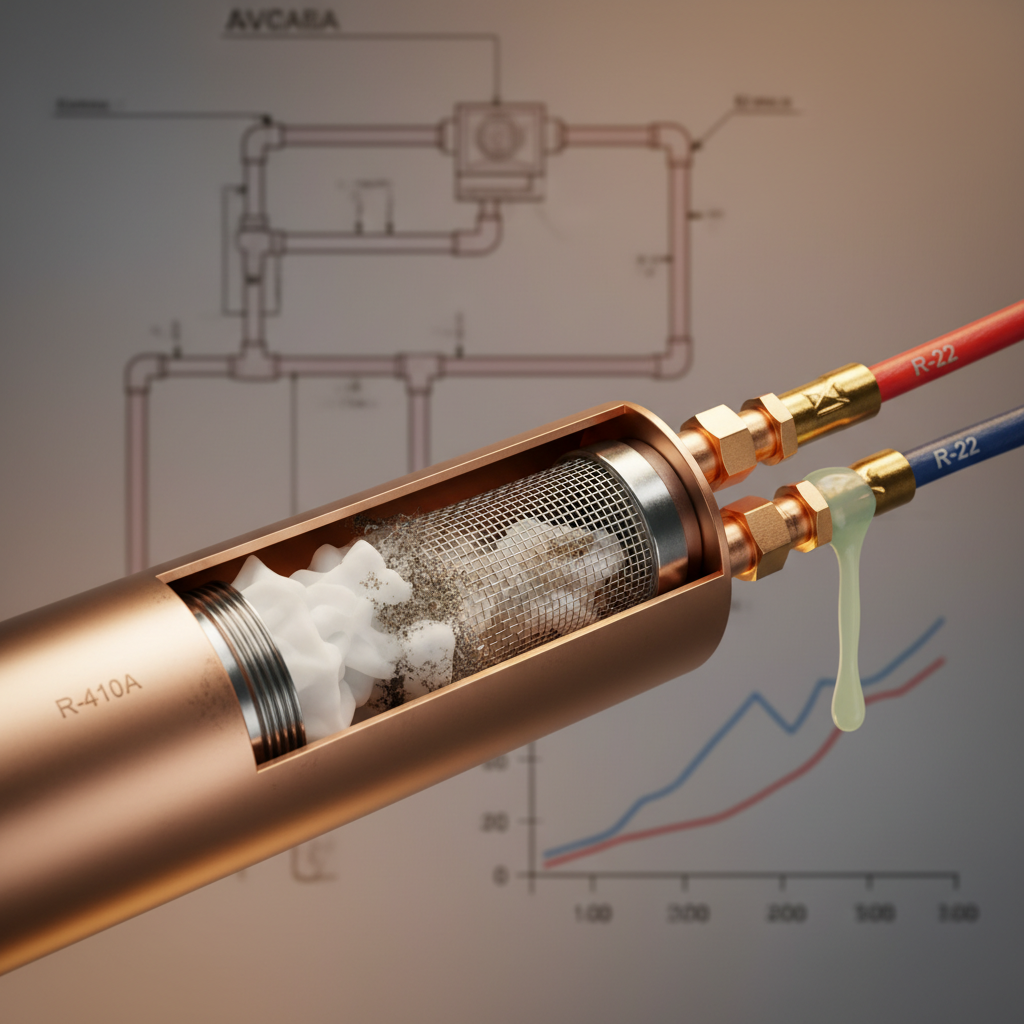

When selecting the right copper filter drier for HVAC systems, there are several key factors to consider. First, it's essential to evaluate the specific refrigerant you will be using. With the ongoing transition from R-410A to newer refrigerants like R-454B, ensure that the filter drier is compatible with the refrigerant type, as this affects efficiency and system reliability. Some filter driers are designed to handle specific refrigerants, and using the wrong one can lead to inadequate moisture removal and system failure.

Another important factor is the system's capacity and design. The size and flow rate of the filter drier should correspond to the HVAC system's specifications. An oversized or undersized filter drier may disrupt the refrigerant flow, leading to performance issues. Furthermore, consider the construction materials and filtration capabilities. A high-quality copper filter drier will have robust construction to withstand the pressures and temperatures within the system, while also providing effective particle and moisture filtration. By taking these factors into account, you can ensure optimal performance and longevity of your HVAC system.

When selecting the right copper filter drier for HVAC applications, understanding the different types available is crucial. The most common types include high-efficiency driers, bi-flow driers, and filter driers with built-in sight glasses. High-efficiency driers are designed to remove moisture and contaminants from refrigerants, significantly improving system reliability. According to a report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), using the appropriate filter drier can enhance system efficiency by up to 25%, reducing energy consumption and operational costs.

Bi-flow filter driers are essential in refrigeration systems that require bidirectional flow, such as heat pumps. They ensure that both heating and cooling operations maintain optimal performance while effectively trapping particulates and moisture. A study by the International Institute of Refrigeration (IIR) indicates that improper filtering can lead to performance losses of up to 15%, emphasizing the need for correctly matched filter driers in HVAC systems.

Moreover, filter driers with built-in sight glasses provide real-time diagnostics, allowing technicians to monitor the refrigerant's condition without further disassembly. This feature proves invaluable in maintaining system health, as noted in industry benchmarks, where proactive maintenance leads to a reduction in refrigerant loss by as much as 30%, ensuring longevity and optimal performance of HVAC systems.

| Type of Copper Filter Drier | Application | Refrigerant Compatibility | Max Operating Pressure (psi) | Typical Size (inches) |

|---|---|---|---|---|

| Liquid Line Filter Drier | Residential and Commercial AC Systems | R-410A, R-22 | 450 | 4 x 12 |

| Suction Line Filter Drier | Refrigeration Systems | R-134A, R-404A | 300 | 5 x 14 |

| Bi-directional Filter Drier | Heat Pump Systems | R-410A, R-32 | 400 | 5 x 12 |

| High-Efficiency Filter Drier | Commercial Refrigeration | R-290, R-448A | 500 | 6 x 15 |

| Standard Filter Drier | General HVAC Applications | R-22, R-410A | 350 | 4 x 10 |

When selecting a copper filter drier for HVAC systems, assessing its capacity and efficiency is crucial to ensure optimal performance. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), filter driers should be sized according to the refrigeration system's capacity, typically measured in tons. A commonly accepted guideline is that one pound of refrigerant per ton of cooling capacity requires 1.5 ounces of filter drier, ensuring effective moisture and contaminant removal while maintaining system efficiency.

Efficiency is equally important when choosing a copper filter drier. In practice, filter driers should be rated by their pressure drop and moisture removal efficacy. The Institute of Refrigeration reports that a pressure drop of less than 3 psi is ideal for maintaining system efficiency and avoiding unnecessary strain on the compressor. Additionally, filter driers with a moisture removal efficiency of over 99% can significantly reduce the risk of compressor failure and maintain the longevity of the HVAC system, demonstrating the importance of selecting a high-quality product tailored to specific HVAC needs.

When selecting a copper filter drier for HVAC systems, avoiding common pitfalls can significantly enhance performance and longevity. One major mistake is underestimating the system's specific refrigerant and application requirements. According to a report by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), mismatched components can lead to reduced efficiency and increased wear on the system, often resulting in premature failures. Ensuring compatibility with the type of refrigerant—be it R-410A or R-22—is crucial for optimal operation.

Another frequent error is neglecting the filter drier's moisture removal capacity. The North American HVAC Equipment Market Report indicates that moisture levels above acceptable thresholds can lead to issues like acid formation and corrosion. Choosing a filter drier with insufficient moisture absorption can lead to system failure, as highlighted by the ASHRAE, which emphasizes that adequate dehumidification is vital for both residential and commercial HVAC systems. Investing time in selecting a filter drier that balances capacity and efficiency according to the specific demands of your HVAC setup can save considerable costs in the long run.

Proper maintenance of your copper filter drier is essential for the longevity and efficiency of your HVAC system. Regular upkeep can significantly extend the lifespan of the filter drier, which could contribute to the overall performance of your HVAC system. According to industry experts, a well-maintained HVAC system can last upwards of 20 years, potentially even longer if steps are taken to preserve its components. One effective method is routinely checking and cleaning your filter drier, as clogged filters can lead to increased energy consumption and premature system failure.

In addition to cleaning, consider implementing a comprehensive maintenance schedule to monitor the health of your HVAC system. Reports indicate that home appliance maintenance, such as descaling and changing filters, can save homeowners thousands by improving efficiency and reducing energy costs. Furthermore, ignoring regular maintenance tasks—like checking the copper filter drier—can shorten the lifespan of your air conditioning unit by up to 5 years. By investing time and effort into maintaining these components, you not only safeguard your HVAC investment but also enhance the comfort of your living environment.