As we look ahead to 2025, the importance of understanding the evolving landscape of Refrigeration Evaporator Coils becomes increasingly significant for industry stakeholders. According to the latest market analysis by the International Institute of Refrigeration, the global demand for advanced evaporator coils is anticipated to grow at a compound annual growth rate (CAGR) of 7.5%, reaching a market value of $3.3 billion by 2025. This growth is largely driven by innovations in energy efficiency and sustainable design, responding to both regulatory pressures and consumer preferences for eco-friendly solutions.

Industry expert Dr. Emily Harper, a leading researcher in thermal management systems, emphasizes, "The future of Refrigeration Evaporator Coils lies in their adaptability and integration into smart systems that enhance performance while minimizing environmental impact." This sentiment captures the essence of where the industry is heading: a focus not only on traditional efficiency metrics but also on smart technology integration that will shape the functionality of refrigeration systems in diverse applications.

As we delve into the top trends shaping the future of Refrigeration Evaporator Coils, it becomes essential to recognize the interconnections between technological advancements, regulatory frameworks, and market needs. From advancements in materials to the incorporation of IoT capabilities, these trends are set to define how refrigeration systems operate and innovate in the coming years.

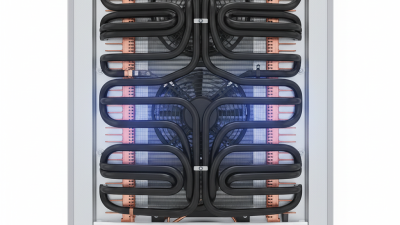

As we approach 2025, the refrigeration industry is witnessing a significant shift driven by emerging technologies that enhance the efficiency and performance of evaporator coils. One of the notable trends is the integration of advanced materials that improve thermal conductivity and reduce weight. These innovative materials not only enhance the overall efficiency of refrigeration systems but also contribute to environmental sustainability by minimizing energy consumption.

Another key development is the incorporation of smart technology into refrigeration evaporator coils. With the rise of the Internet of Things (IoT), these coils can now communicate with other system components, enabling real-time monitoring and predictive maintenance. This connectivity allows for optimized performance and energy management, greatly reducing operational costs while ensuring that the refrigeration units function effectively under varying load conditions.

Furthermore, the adoption of eco-friendly refrigerants is rapidly gaining traction, aligning with global efforts to combat climate change. New refrigerants have been developed to perform at optimal levels while possessing lower global warming potential. This transition not only satisfies regulatory requirements but also empowers businesses to embrace a more sustainable approach to refrigeration. Together, these trends signal a transformative period for evaporator coils, paving the way for more efficient, sustainable, and intelligent refrigeration solutions in the coming years.

Sustainable practices in the production of refrigeration evaporator coils are becoming increasingly crucial as industries strive to reduce their environmental impact. The focus on sustainability begins with the selection of raw materials. Manufacturers are exploring alternatives to traditionally used metals and plastics, aiming to utilize recycled or eco-friendly materials that can minimize waste and energy consumption. Incorporating natural refrigerants in the design process is also gaining traction, as these substances have lower global warming potential compared to conventional chemicals.

Additionally, energy efficiency plays a pivotal role in the sustainability of evaporator coils. Modern production techniques emphasize the development of coils that not only enhance cooling performance but also consume less energy over their lifetime. This not only reduces the operational costs for users but significantly decreases greenhouse gas emissions. Furthermore, various companies are implementing environmentally friendly manufacturing processes, such as reducing water usage and minimizing emissions during production. As these practices become the norm, the refrigeration industry is poised to make significant strides toward achieving a more sustainable future.

Sustainable Practices in the Production of Refrigeration Evaporator Coils

| Trend | Description | Impact on Sustainability | Implementation Year |

|---|---|---|---|

| Eco-Friendly Refrigerants | Use of natural refrigerants like CO2 and hydrocarbons. | Reduces ozone depletion and global warming potential. | 2023 |

| Enhanced Energy Efficiency | Design improvements for better heat exchange. | Lowers energy consumption in cooling processes. | 2024 |

| Recycled Materials | Components made from recycled metals and plastics. | Decreases resource extraction and waste production. | 2025 |

| Smart Technology Integration | Use of IoT for monitoring and efficiency optimization. | Enhances operational efficiency and reduces emissions. | 2023 |

| Modular Designs | Flexible and scalable evaporator coil systems. | Minimizes materials use and allows for easy upgrades. | 2024 |

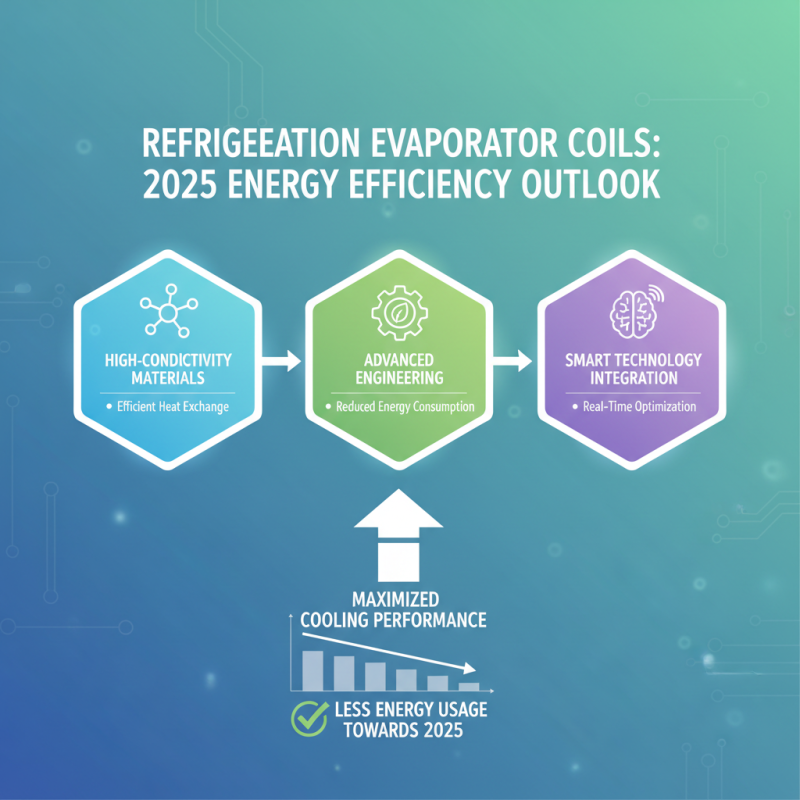

As we move towards 2025, energy efficiency is set to become a paramount consideration in the design and application of refrigeration evaporator coils. Innovations in materials and engineering techniques are paving the way for coils that require less energy while maximizing cooling performance. For instance, advancements in high-conductivity materials allow for more efficient heat exchange, reducing the energy needed to maintain desired temperature levels. Additionally, the incorporation of smart technology into evaporator coils enables real-time monitoring and optimization of energy consumption, allowing for adjustments based on specific refrigeration needs.

Moreover, the trend towards environmentally friendly refrigerants has spurred developments in evaporator coil designs that minimize greenhouse gas emissions. These new systems are not only more energy-efficient but also aligned with global sustainability goals. Manufacturers are increasingly focusing on designs that improve thermal performance while reducing the overall footprint of refrigeration systems. This shift not only cuts operational costs but also meets the growing demand for sustainable practices in the refrigeration industry, establishing a balance between performance and environmental responsibility.

In 2025, the refrigeration industry is expected to witness a significant transformation in the design of evaporator coils, driven by several pivotal market trends. One of the primary influences will be the push for energy efficiency. Manufacturers are increasingly adopting advanced materials and technologies that enhance thermal conductivity while minimizing energy consumption. This shift not only aligns with global sustainability goals but also meets the rising consumer demand for eco-friendly products.

Furthermore, the integration of smart technology in refrigeration systems is becoming prevalent. With the Internet of Things (IoT) in play, evaporator coils are being designed with sensors to monitor performance in real time, allowing for predictive maintenance and optimized operation. This innovation enables businesses to reduce downtime and improve overall efficiency, catering to a market that values responsiveness and reliability.

Tip: When selecting refrigeration evaporator coils, consider those with enhanced thermal efficiency ratings. Additionally, look for options that offer smart connectivity features to future-proof your investment against upcoming technological advancements. Keeping an eye on evolving standards can also help you stay compliant and competitive in the market.

As we approach 2025, the refrigeration industry faces a myriad of challenges related to evaporator coils, which play a crucial role in cooling systems. Key issues include energy efficiency and environmental impact. According to a report from the International Institute of Refrigeration, refrigeration accounts for approximately 15% of global electricity consumption, with evaporator coils contributing significantly to this figure. This underscores an urgent need for advancements in coil technology that enhance efficiency while minimizing energy consumption.

Addressing these challenges, innovative solutions are emerging in the field of refrigerant alternatives and coil design. Many experts suggest a shift towards natural refrigerants, such as CO2 and ammonia, which have a lower global warming potential compared to traditional options. Furthermore, advancements in coil materials and design, including the use of microchannel technology, can increase surface area and improve heat transfer efficiency, potentially reducing energy usage by up to 30%.

In preparation for the upcoming regulatory changes, 2025 is poised to be a pivotal year for adopting sustainable practices in refrigerant usage and evaporator coil technology. This transition not only aligns with environmental goals but also promises long-term cost savings for businesses worldwide.