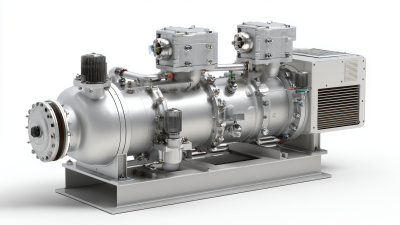

The landscape of compressor maintenance is evolving. One crucial component in this progress is the Filter Dryer For Compressor. According to a recent industry report, up to 60% of compressor failures are linked to moisture and contaminants. A reliable filter dryer can prevent these issues, ensuring longevity and efficiency.

Filter dryers are essential for protecting compressors from damaging particles and moisture. The data shows that implementing these systems can reduce repair costs significantly, often by 30% or more. The right filter dryer can enhance system performance, leading to increased energy savings over time. However, not all products offer the same benefits. Companies must evaluate options carefully.

In this rapidly changing industry, the need for innovative solutions is clear. Understanding the specifics of filter dryers can lead to smarter choices. It's crucial to engage with these details to achieve optimal results. Yet, many remain unaware of the complexities involved. This oversight could result in diminished efficiency and increased operational costs. Recognizing the importance of a suitable Filter Dryer For Compressor is vital for a successful operational strategy.

In 2026, filter dryer technology for compressors is evolving rapidly. These innovations enhance efficiency and protect equipment. Advances focus on moisture removal and contaminant filtration. This ensures that compressed air remains clean and dry. Reliable filters can significantly extend the lifespan of compressors.

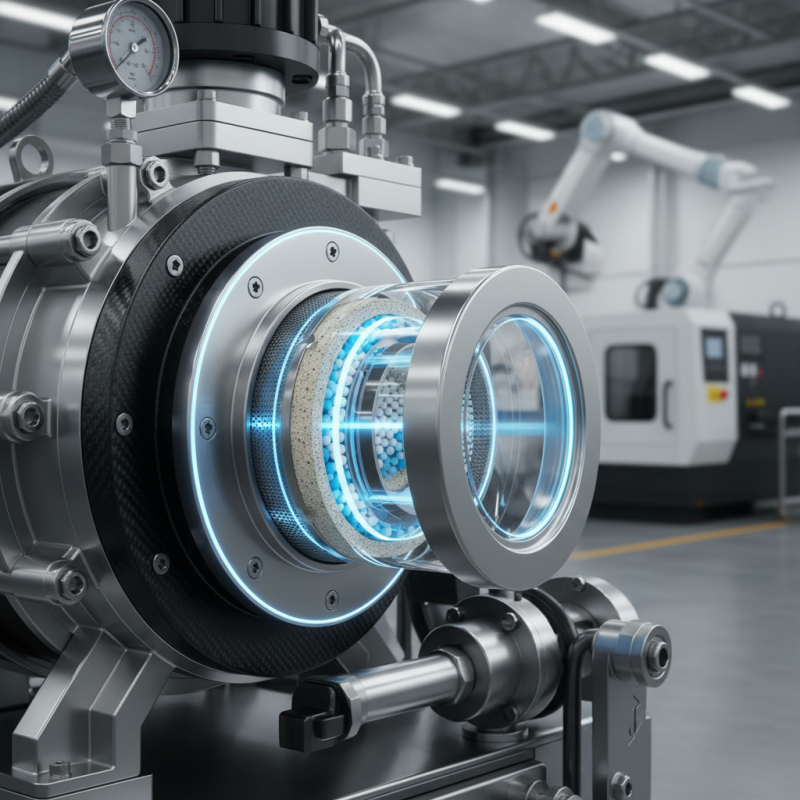

New designs incorporate user-friendly features. Some models include advanced sensors for monitoring. These sensors provide real-time data on performance. However, not all models are perfect. Regular maintenance can be a hassle for users. Many struggle to keep up with cleaning schedules. Neglecting this can lead to suboptimal performance.

The benefits of these filter dryers are clear. They prevent damage from moisture, which can cause malfunctions. Users report more consistent operation and reduced downtime. Yet, the cost of these advanced systems can be a barrier. Some might question if the investment is worth it. Each compressor application may require a different approach. Finding the right filter dryer might take some time and effort.

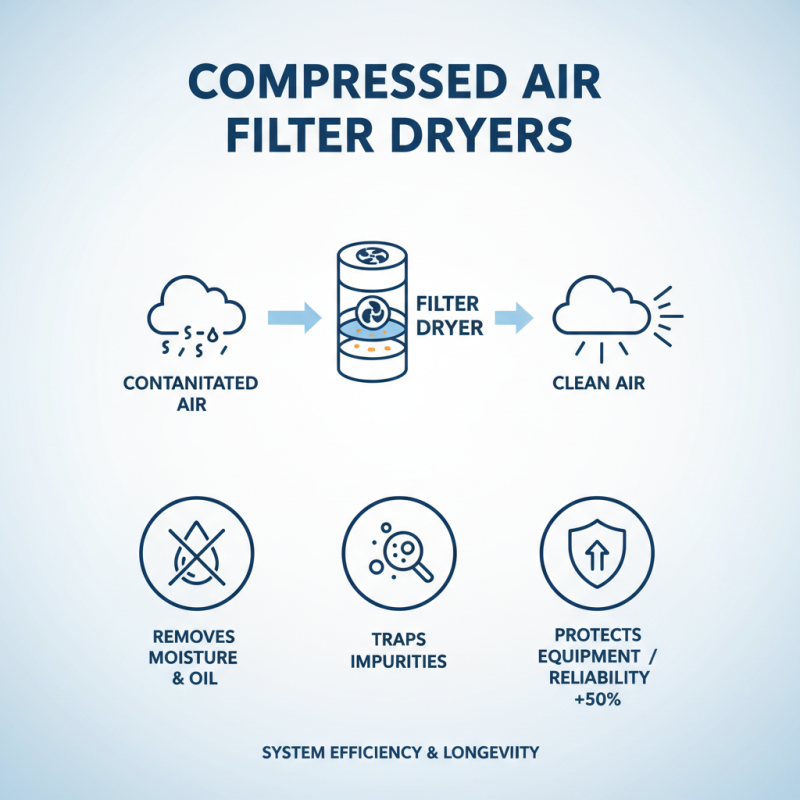

Filter dryers play a vital role in compressed air systems. They remove moisture, oil, and impurities from compressed air. This process protects downstream equipment and improves efficiency. According to industry reports, using a filter dryer can enhance system reliability by up to 50%.

One of the key benefits is reducing wear and tear on machinery. Moisture in air lines can lead to corrosion. This damages components over time. A filter dryer mitigates this risk, extending the lifespan of equipment. Protecting components can save significant repair costs in the long run.

Tips: Regular maintenance of filter dryers is essential. Always check for blockages and replace filters as needed. Additionally, consider monitoring your system’s pressure levels. Maintaining optimal pressure can improve overall efficiency. Choosing the right size and type of filter dryer matters. Too small may lead to inefficiencies, while over-sizing may result in wasted resources.

In 2026, the variety of filter dryers for compressors is expected to expand significantly. Key types include desiccant dryers, which use materials that absorb moisture, and coalescing filters that remove liquid water and particulates. According to a recent industry report, these units can reduce energy costs by up to 30% when compared to traditional systems.

Applications vary widely across industries. For instance, desiccant dryers are commonly used in food and beverage manufacturing where moisture control is crucial. In contrast, coalescing filters are ideal for applications in oil and gas sectors, where contaminants must be removed from compressed air. It’s essential to select the right type based on specific needs.

Tips: Regular maintenance is crucial for optimal performance. Neglected dryers may lead to increased energy costs and downtime. Monitoring moisture levels can prevent unexpected failures. Staying informed about the latest technologies in filter dryers can greatly enhance efficiency. Always compare efficiency ratings for better decisions.

Choosing the right filter dryer for your compressor is critical. A filter dryer helps remove moisture and contaminants. This process enhances the efficiency and longevity of your compressor. With the right filter, you’ll notice improved performance and reduced maintenance costs.

When selecting a filter dryer, consider the size of your compressor. Not all dryers fit every system. Check the specifications carefully. Understand the flow rate and pressure requirements. A mismatch can lead to inefficiencies or damage.

Here are some tips to keep in mind:

- Evaluate your operating conditions.

- Regularly inspect your filter dryer.

- Know when to replace it.

Sometimes, the best choice may not be clear. It's easy to overlook details like operating temperature. This oversight can affect efficiency. Take your time when making a decision. Be aware of the long-term impacts on your compressor system.

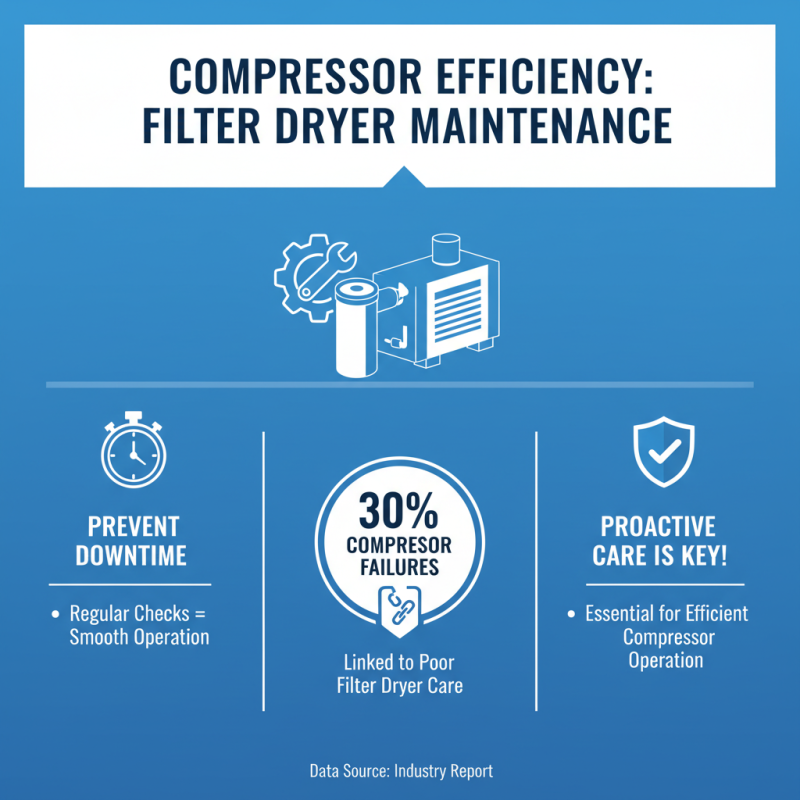

Proper maintenance of filter dryers is essential for efficient compressor operation. Regular checks can prevent costly downtime. Data shows that nearly 30% of compressor failures are linked to inadequate filter dryer maintenance. This highlights the need for proactive care.

One important tip is to schedule routine inspections. Look for signs of wear or damage. Replace filters according to the manufacturer’s guidelines, but also trust your judgment. Sometimes, filters need changing sooner due to harsh operating conditions.

Another key aspect is to monitor system pressure regularly. A drop in pressure may indicate a clogged filter. This can affect overall system efficiency. Many professionals suggest using differential pressure gauges for real-time monitoring. A small investment here can yield more significant savings in performance.

Lastly, keep the filter dryer area clean. Dust can accumulate and affect airflow. This simple act often gets overlooked but is crucial. Neglecting this step can lead to unforeseen days of downtime. Keep it tidy; your compressor will thank you.