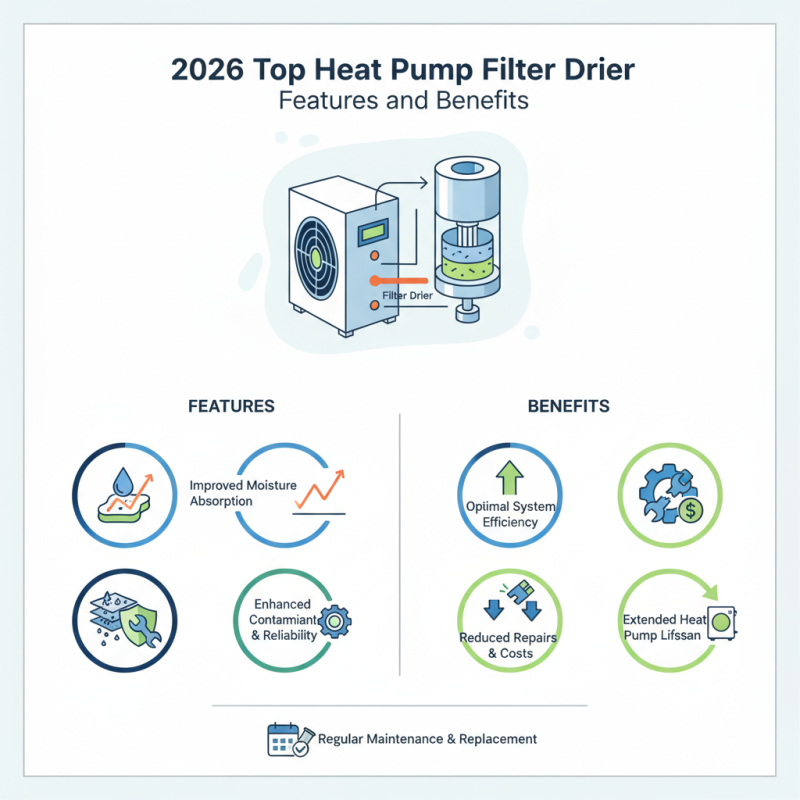

In 2026, the heat pump filter drier plays a crucial role in HVAC systems. This component is designed to remove moisture and contaminants. Ensuring the system operates efficiently is vital. A well-functioning heat pump filter drier enhances reliability. It directly impacts the longevity of the heat pump.

The features of modern heat pump filter driers include improved filtration and higher durability. Many units now offer better moisture absorption. These advancements lead to optimal performance in varying climates. However, not all filter driers are created equal. Many people overlook the importance of choosing the right one.

Understanding the benefits of a heat pump filter drier is essential. It can help prevent system failures and costly repairs. Still, some users may underestimate its importance. Regular maintenance and replacement can make a significant difference. It’s worth considering how these features affect overall HVAC efficiency.

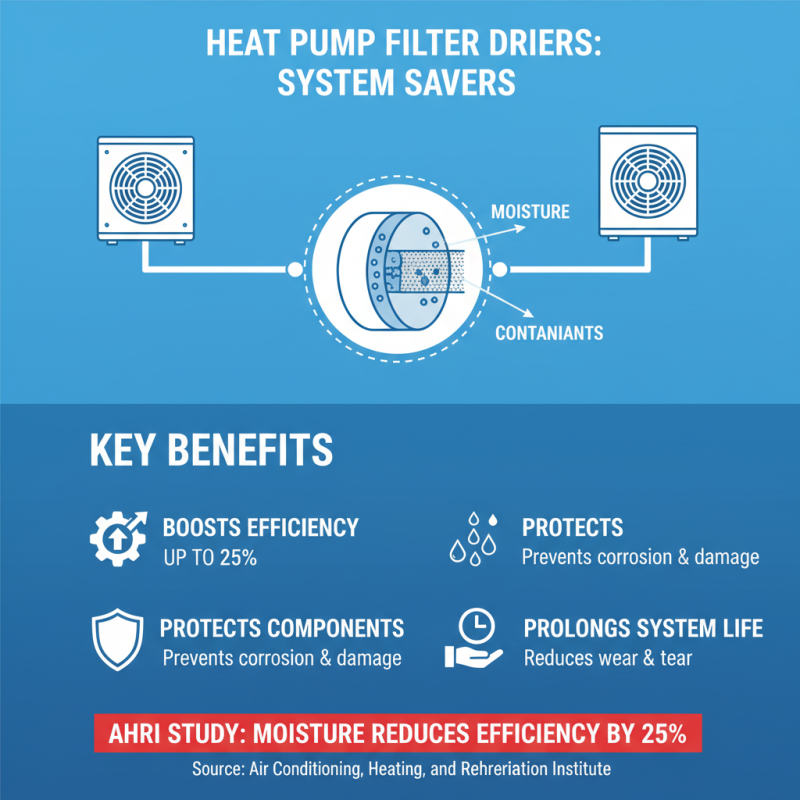

Heat pump filter driers play a crucial role in maintaining the efficiency and longevity of heating and cooling systems. These components remove moisture and contaminants from the refrigerant, protecting the entire system. A study from the Air Conditioning, Heating and Refrigeration Institute (AHRI) reveals that moisture can reduce efficiency by up to 25%. This statistic underscores the importance of effective moisture control in HVAC systems.

The functionality of heat pump filter driers lies in their filtration capabilities. They typically include desiccant materials that absorb water vapor and filter out solid particles. Some models also feature sight glasses, helping technicians monitor the refrigerant's condition. Data from the Department of Energy indicates that improper filtration can lead to premature compressor failure. Faulty systems can result in costly repairs and operational downtime.

However, selecting the right filter drier isn't always straightforward. Different systems require specific types for optimal performance. Many consumers overlook these details, assuming all filter driers are the same. In reality, compatibility matters significantly. Technicians often find themselves dealing with improper installations, leading to inefficiencies and system failures. Being well-informed about these components can help in making better choices.

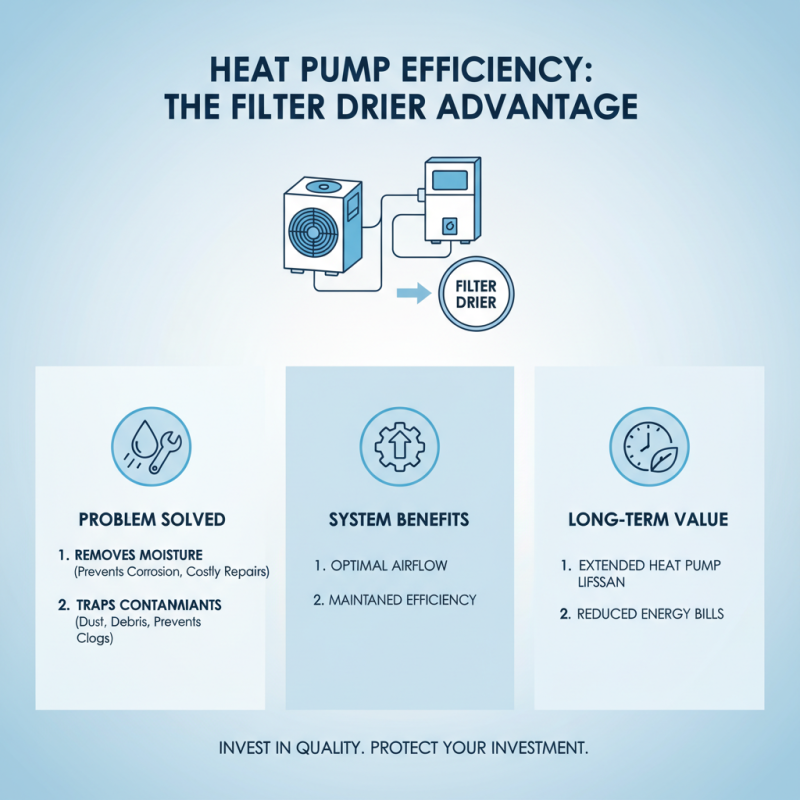

When choosing a heat pump filter drier for 2026, understanding its key features is essential. These components are vital for maintaining system efficiency. A high-quality filter drier effectively removes moisture and impurities from the refrigerant. This process prevents corrosion and extends the lifespan of heat pumps.

One standout feature is the improved desiccant material. This advanced material enhances moisture absorption. It ensures that even the smallest amounts of water are captured. The result? A more reliable system that operates smoothly. Additionally, modern filter driers often include a larger surface area. This design allows for better refrigerant flow while trapping contaminants.

Some filter driers also have built-in sight glasses. This transparent feature makes it easier to monitor refrigerant condition. Users can quickly detect any issues. Yet, it’s crucial to remember that not all units are created equal. The effectiveness can vary widely. Regularly checking performance is necessary. Ultimately, making an informed choice will help in maximizing the benefits of your heating system.

High-quality filter driers play a crucial role in heat pumps. They help maintain the system's efficiency by removing moisture and contaminants. Moisture can cause corrosion, leading to expensive repairs. Contaminants like dust and debris can clog the system, reducing airflow. Using a filter drier means a longer lifespan for the heat pump.

The benefits extend beyond just efficiency. A good filter drier can enhance system performance. It allows for better heat transfer. This translates to improved energy savings over time. In some cases, users notice a significant reduction in monthly energy bills. However, not all filter driers are created equal, and it’s essential to choose wisely.

There can be downsides to inferior products. Poorly made filter driers might not filter effectively, allowing harmful substances to enter the system. This can lead to premature failures. Regular maintenance is necessary, but the initial choice is crucial. When investing in a heat pump, consider the quality of the filter drier. It's an important decision that shouldn’t be overlooked.

The choice between traditional and advanced filter drier designs can significantly impact the efficiency of heat pumps. Traditional designs rely on simple filtering methods. They mainly remove moisture and particulates. However, their effectiveness may decline over time, leading to reduced performance.

In contrast, advanced filter drier designs incorporate newer technologies. These can trap even smaller particles, improving overall system reliability. They often feature molecular sieves that absorb moisture more effectively. This can prevent system failures related to humidity. Additionally, some advanced models come with indicators. These alert users when a replacement is needed, ensuring optimal system performance.

Tips: Regular maintenance is crucial. Even the best filter drier can falter without proper care. Inspect your system every few months. Look for signs of wear or moisture buildup. Investing in a higher-quality filter drier may pay off in the long run.

When installing a heat pump filter drier, proper placement is crucial. Ensure the filter drier is located close to the compressor. This helps in efficient moisture removal and enhances the system's overall performance. A well-located filter can reduce stress on the components. The area should be clean and accessible for maintenance.

Regular maintenance is essential for optimal performance. Check the filter drier for signs of wear or blockage. If you notice any unusual noise or reduced efficiency, it may be time to replace the unit. Remember to flush the system before installation. This clears out any debris that could hinder performance. Always refer to specific guidelines, as systems may vary. Ignoring maintenance can lead to costly repairs and inefficiency.

Pay attention to refrigerant levels. A system running low on refrigerant could affect the filter drier’s operation. Monitoring pressures can help detect issues early. Be mindful of these details to avoid larger problems down the line. Keeping an eye on performance and addressing minor issues promptly will extend the life of the heat pump system.

| Feature | Benefits | Installation Tips | Maintenance Tips |

|---|---|---|---|

| High Moisture Removal | Prevents compressor damage and improves efficiency. | Ensure proper sizing for the system to optimize performance. | Inspect filters regularly to ensure optimal flow and performance. |

| Corrosion Resistance | Increases lifespan and reliability of the unit. | Install in a dry location to minimize corrosion factors. | Clean external surfaces regularly to prevent buildup. |

| Compact Design | Saves space in HVAC systems. | Follow manufacturer's guidelines for optimal placement. | Check for obstructions around the unit to maintain airflow. |

| High Filtration Efficiency | Improves overall air quality by capturing contaminants. | Use high-quality sealing materials during installation. | Replace filters as recommended to ensure consistent performance. |

| Easy Access Ports | Simplifies servicing and maintenance procedures. | Position access ports where they are easily reachable. | Regularly check access points to ensure they are free of debris. |