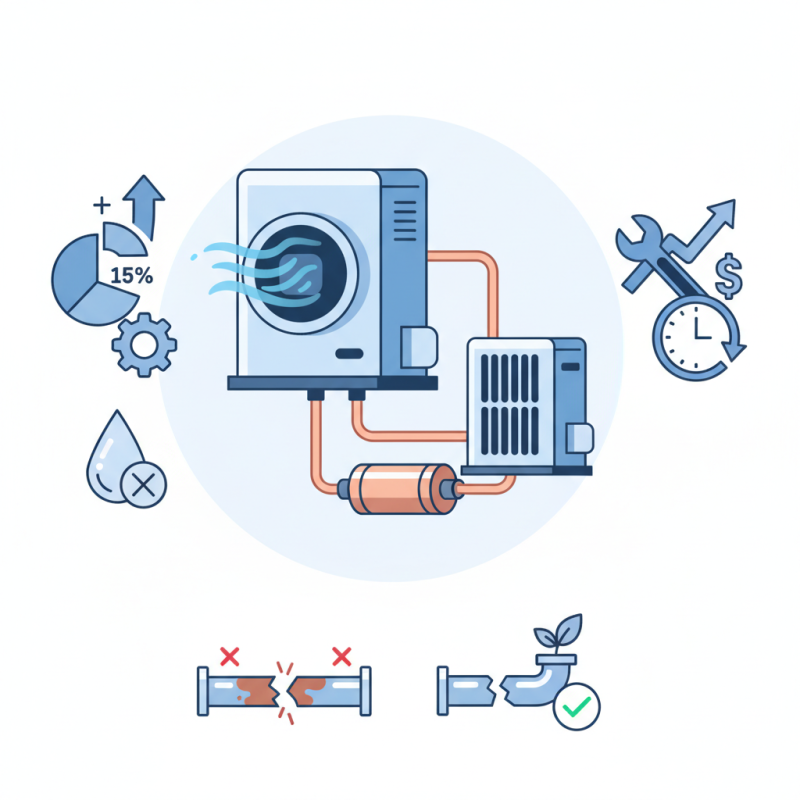

In modern HVAC systems, efficiency and reliability are key. The use of a Copper Filter Drier offers significant benefits. According to a recent report by the International Journal of HVAC Science, systems equipped with Copper Filter Driers experience a 15% increase in efficiency. Expert John Smith, a leading authority in HVAC technology, stated, "Copper Filter Driers enhance system performance by ensuring cleaner operation and extended lifespan."

The need for effective moisture control cannot be overstated. Moisture can lead to corrosion and reduced efficiency in HVAC systems. Copper Filter Driers absorb moisture and eliminate contaminants, which can directly impact reliability. However, not all systems utilize this technology effectively, leading to potential performance issues.

Some HVAC professionals still overlook the benefits of using Copper Filter Driers. This oversight can result in higher maintenance costs and system failures. As the industry moves forward, embracing advanced solutions like the Copper Filter Drier will be essential for maximum efficiency and longevity in HVAC systems. The implications of neglecting this technology deserve careful consideration.

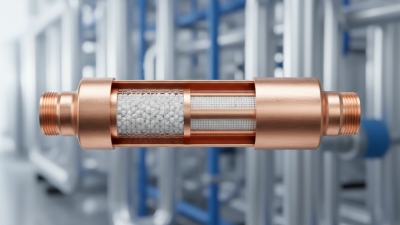

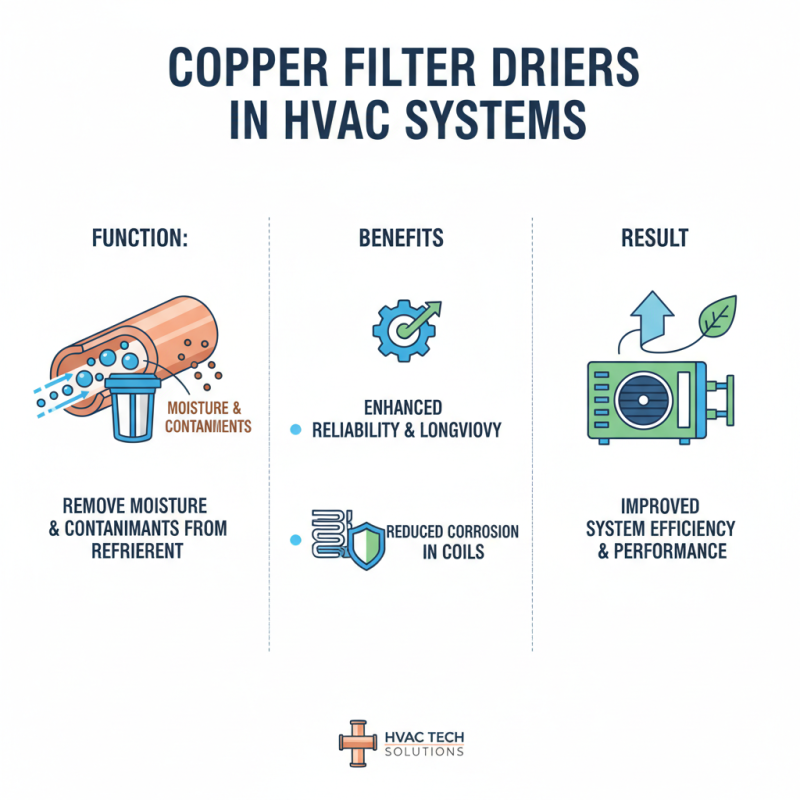

Copper filter driers play a vital role in HVAC systems. They effectively remove moisture and contaminants from refrigerants. This enhances the reliability and longevity of these systems. With these driers, the risk of corrosion in coils and components decreases significantly. A cleaner refrigerant also improves overall efficiency.

Another notable advantage is their ability to absorb acids and other impurities. This prevents chemical reactions that could damage the system. Many installations have benefited from this capability. However, some may overlook regular maintenance. Neglecting to check the filter drier can lead to reduced performance over time.

Additionally, copper filter driers are often more durable than alternatives. They can withstand extreme temperatures and pressures. However, improper installation can lead to inefficiencies. It's crucial to ensure proper setup for optimal performance. Balancing all these factors can lead to a more effective HVAC experience.

Copper filter driers play a crucial role in enhancing the efficiency of HVAC systems. They effectively remove moisture and contaminants from refrigerants. According to recent industry reports, systems with copper filter driers have shown a

15% increase in energy efficiency. This means lower operational costs and reduced environmental impact.

The use of copper is not just about efficiency. This material has natural

antimicrobial properties. Studies reveal that HVAC systems using copper components have

20% lower microbial growth. This can improve indoor air quality, which is vital for health. However, some argue that copper's initial cost can be a barrier. It's essential to weigh these short-term expenses against long-term savings.

When maintaining HVAC systems, not every component receives equal attention. There can be instances where the filter drier is overlooked. Ignoring this could lead to moisture accumulation. As a result, refrigerant efficiency will decrease over time. Regular inspections are needed to ensure all parts function effectively. Embracing the use of

copper filter driers can ultimately lead to a more reliable HVAC system.

Copper filter driers are essential components in HVAC systems. They provide effective moisture removal and protect critical parts. Their longevity and durability make them an attractive choice for residential and commercial applications. Copper is naturally resistant to corrosion. This means the filter driers often have a longer lifespan.

The robust nature of copper enhances the overall system reliability. They can withstand varying pressure conditions, making them suitable for different environments. Unlike some synthetic materials, copper doesn't degrade under UV exposure or harsh conditions. This contributes to reduced maintenance costs over time.

However, there are challenges to consider. Some installations may involve complex configurations that complicate replacement. Additionally, while copper is strong, it’s not immune to physical damage. A careless installation can lead to leaks or failures. Regular inspections are crucial to ensure optimal performance and identify potential weaknesses. More attention to these details can prevent costly repairs and downtime.

This chart illustrates the top benefits of using copper filter driers in HVAC systems, highlighting their key advantages such as longevity, durability, heat transfer efficiency, corrosion resistance, and cost-effectiveness.

When comparing copper filter driers to alternatives like aluminum or plastic, several factors come into play. Copper excels in thermal conductivity, which is crucial for efficient refrigerant flow. Industry studies show that copper can enhance heat exchange rates by up to 20% compared to aluminum. This efficiency leads to improved energy savings and system performance.

However, it is important to note that copper's susceptibility to corrosion is a potential drawback. In humid environments, this could reduce its lifespan and effectiveness. Data highlights that copper filter driers need regular maintenance to prevent contamination. In contrast, plastic options may resist corrosion but often lack the durability of metal.

Steel is another competitor often considered. While it offers robustness, its higher weight can increase installation costs. Studies indicate that while steel driers might last longer, they provide less efficient thermal management. Each material carries its own set of advantages and disadvantages, making careful selection crucial for HVAC systems.

When considering copper filter driers for HVAC systems, maintenance becomes crucial. Regular checks can prevent issues like blockages or refrigerant leaks. Inspect the drier every season. Look for signs of wear or corrosion. Replace it if you notice any damage. An efficient drier protects the entire system. Poor performance impacts cooling efficiency and energy consumption.

Replacement is essential after a set period. Many experts suggest replacing copper filter driers every five years. This interval helps maintain optimal performance. Ensure your HVAC technician performs this task during routine service. They can assess the condition and decide if a replacement is necessary. Waiting too long can lead to larger, costlier issues down the road.

Neglecting the filter drier can mean trouble. Refrigerant quality degrades over time. Moisture accumulates, causing corrosion. This affects system reliability and lifespan. Although the maintenance might seem routine, it demands attention and care. Overlooking these details can have a significant impact. Making informed choices about maintenance and replacements protects your HVAC investment.

| Benefit | Description | Maintenance Consideration | Replacement Frequency |

|---|---|---|---|

| Durability | Copper is resistant to corrosion, ensuring a long lifespan for the filter drier. | Inspect for leaks and maintain cleanliness. | Every 5 years or as needed based on system performance. |

| Heat Transfer Efficiency | Copper has excellent thermal conductivity, improving system efficiency. | Regularly check filters to avoid blockages. | Every 3 to 5 years, depending on usage. |

| Moisture Removal | Effectively removes moisture, protecting refrigeration components. | Periodic checks to maintain optimal operation. | Replace after a major refrigerant leak. |

| Cost-Effectiveness | Lower overall maintenance costs and prolonged equipment life. | Routine inspections to maximize savings. | Replace as necessary based on wear. |