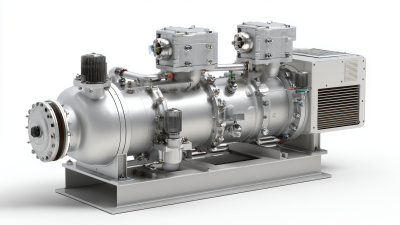

In the world of industrial applications, utilizing a "Filter Dryer for Compressor" can drastically enhance operational efficiency. According to Mark Thompson, a leading expert in compressor systems, "Implementing a filter dryer can significantly reduce moisture content and protect equipment." Moisture in compressed air can lead to corrosion and malfunction, which is a common concern in many industries.

The advantages of using a filter dryer are immense. They not only extend the lifespan of compressors but also improve productivity. Many users report reduced downtime and maintenance costs. However, the initial investment in filter dryers might seem daunting for some. This hesitation can lead to missed opportunities for improved performance.

Adopting a filter dryer for compressor systems can seem overwhelming. Yet, understanding its benefits reveals a landscape of potential gains. It’s essential to weigh these advantages against traditional methods. Recognizing the need for change is the first step towards operational excellence.

Filter dryers play a crucial role in compressor systems. They ensure the air or gas remains clean and dry, which is vital for optimal performance. A dry environment prevents rust and corrosion in the system components. It also minimizes the wear and tear that can lead to costly repairs.

These devices remove moisture efficiently, stopping it from forming ice in the lines. This reduces system failures and maintenance downtime. They also filter out impurities like dust and dirt. A cleaner system extends equipment life and enhances energy efficiency. The benefits are clear, yet some may overlook the need for regular maintenance on these filter dryers. Neglecting this can lead to decreased performance.

Investing in quality filter dryers makes a noticeable difference. While the initial cost may raise concerns, consider the long-term savings. The reduced energy consumption and fewer repairs will offset the upfront expense. Failing to address these needs could lead to bigger problems down the line. It’s essential to evaluate the entire system regularly to ensure everything functions smoothly.

Moisture in compressor systems can cause significant issues. It leads to corrosion, reduced efficiency, and potential failure. Removing moisture is crucial for maintaining optimal performance. A filter dryer plays a key role in this process. It effectively traps moisture, ensuring that compressors operate smoothly.

Consider the implications of moisture buildup. It can cause irreversible damage over time. Parts may corrode, leading to costly repairs. By using a filter dryer, you can protect your investment. Enhanced reliability increases the overall lifespan of the compressor. Regular moisture removal can also improve energy efficiency. This results in lower operational costs, a benefit most operators appreciate.

Another crucial aspect to reflect on is maintenance. While filter dryers are effective, they need regular checks. Accumulated moisture in filters can hinder performance. It's essential to monitor and replace them as needed. Thin layers of buildup can go unnoticed but lead to issues. Understanding and addressing these subtle points can make a significant difference in performance and longevity.

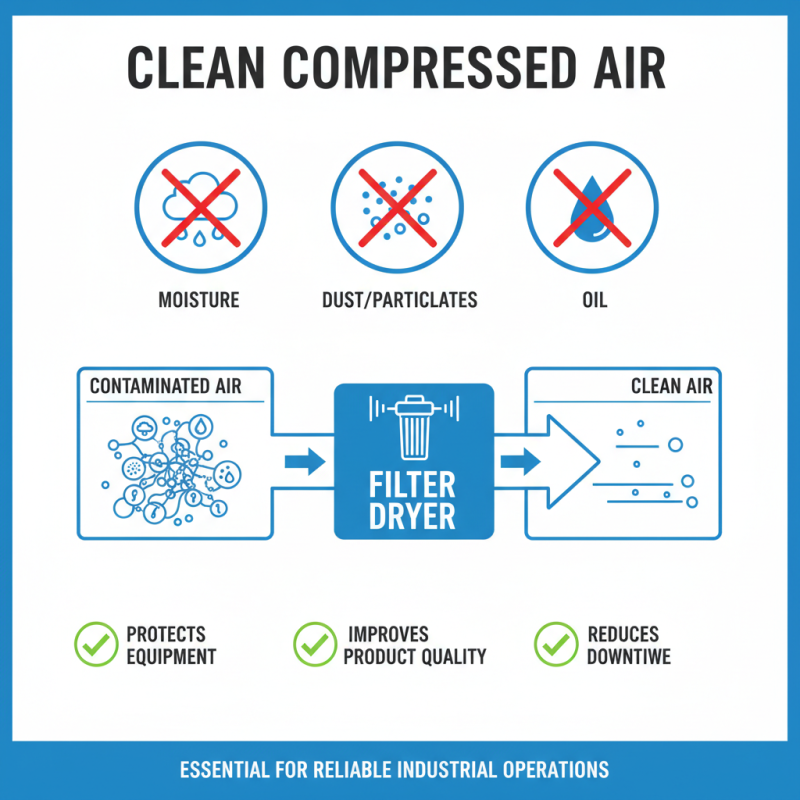

Compressed air systems are vital in various industries. However, the air can contain contaminants. Dust, water, and oil can compromise quality. This is where filter dryers come into play. They significantly improve the quality of compressed air. By removing moisture and particulates, they ensure cleaner output.

Implementing filter dryers leads to many advantages. They extend the life of downstream equipment. Increased air quality can enhance production efficiency. Plus, it minimizes operational issues related to contamination. However, these systems need regular maintenance. Neglecting this can lead to reduced effectiveness. Users must be vigilant about replacing filters timely.

Continuous monitoring is essential. A breakdown in the filtration system can have serious repercussions. Workers might overlook small warning signs. This could lead to larger problems if not addressed. While filter dryers offer clear benefits, they are not foolproof. Users must stay proactive to maximize their advantages. Thus, understanding their operational needs is vital.

Using filter dryers in compressor systems presents significant energy efficiency gains. According to a report by the U.S. Department of Energy, compressed air systems can consume up to 30% of a facility's energy costs. Implementing filter dryers helps reduce this waste. By removing moisture and particulates, these systems operate more smoothly and require less energy to maintain optimal performance.

One interesting fact: filter dryers can lead to energy savings of 15% to 30%. This efficiency comes from reduced pressure drops and less energy wasted on moisture management. Systems with filter dryers often experience extended equipment lifespan. Pumps and compressors face less strain, which translates to lower maintenance costs.

Tip: Regularly monitor filter conditions. Clogged filters can increase energy consumption. Cleaning or replacing filters keeps systems running efficiently.

Another key point is the potential downside. Initial investments for filter dryers can be high. However, the long-term savings often justify these costs. Systems need proper integration and setup. It is crucial to assess each setup's specific needs to maximize benefits.

Tip: Always consider your facility’s specific flow rates and moisture levels before choosing a system.

Using filter dryers in compressor systems can significantly reduce maintenance costs. Studies show that systems with filter dryers can lower maintenance expenditures by up to 30%. This is due to the elimination of particulates and moisture in compressed air. When moisture accumulates, it can lead to corrosion and damage within the system. Regular maintenance checks can become costly and time-consuming.

Data from industry reports highlight that filtration systems can extend compressor life by 25%. This translates to fewer replacements and repairs. However, not all filter dryers are equal. Some may require frequent replacements, which can ironically increase costs. It's crucial to select the right filter dryer for specific applications.

A proper filtration system not only boosts efficiency but also helps in maintaining optimal performance. Inadequate filtration can lead to pressure drops and energy losses. These factors contribute to higher operational costs. Companies must be vigilant in monitoring filter performance to truly capitalize on the benefits. A slight oversight can lead to significant financial repercussions.

| Benefit | Description |

|---|---|

| Reduced Maintenance Costs | Less frequent need for repairs and replacements, lowering overall service costs. |

| Enhanced Equipment Longevity | Protects compressors from contaminants, extending their operational lifespan. |

| Improved Energy Efficiency | By maintaining optimal operating conditions, energy consumption is reduced. |

| Consistent Air Quality | Removes moisture and particulates, ensuring cleaner compressed air. |

| Reduced Downtime | Minimizes interruptions in production due to system failures. |

| Lower Risk of Contamination | Keeps the compressed air clean, avoiding product defects. |

| Simplified Maintenance Procedures | Easier maintenance schedules can be adopted with filter dryers in place. |

| Cost-Effective Solution | Provides a high return on investment by reducing maintenance and repair costs. |

| Compliance with Industry Standards | Helps meet regulatory standards for air quality in various industries. |

| Ease of Integration | Can be easily added to existing compressor setups without major modifications. |