In the ever-evolving world of HVAC systems, the importance of an AC Filter Drier is often overlooked. Industry expert Dr. Sarah Jenkins emphasizes, "The longevity of HVAC systems largely depends on effective filtration and moisture removal.” This highlights the crucial role of the AC Filter Drier in maintaining system efficiency.

AC Filter Driers are designed to remove contaminants and moisture from refrigerants. This prevents damage and ensures optimal performance. However, many HVAC users underestimate the need for regular maintenance. Day-to-day wear and tear on an AC system can lead to accumulated debris. A neglected filter drier can affect cooling efficiency, potentially resulting in expensive repairs down the line.

Yet, users often find themselves caught in a routine. They forget to check or replace the AC Filter Drier regularly. This oversight can lead to significant challenges. Recognizing the specific signs of inefficiency can be difficult. It is essential to stay attentive to the operational state of your HVAC system. By understanding the benefits of using an AC Filter Drier, one can truly appreciate its value.

AC filter driers play a crucial role in HVAC systems. They are often overlooked but essential for efficient operation. A filter drier removes moisture and contaminants from the refrigerant. This process protects the compressor and other components from damage. Moisture leads to corrosion and can cause system failure.

In addition to moisture control, filter driers trap dirt and debris. These particles can affect system performance. When the drier becomes clogged, it restricts flow. This can lead to higher energy costs and reduced cooling capacity. Regular maintenance is key, but many forget about it. Checking the filter drier should be a priority during HVAC inspections.

Improper installation can also be an issue. If the filter drier is not positioned correctly, it won't function properly. Gaps or leaks can compromise the entire system. It’s often easier to overlook these details. However, doing so can lead to bigger problems down the line. Energy efficiency is impacted, and costly repairs may follow. Proper attention can enhance the lifespan of your HVAC.

AC filter driers play a crucial role in maintaining HVAC system efficiency. They remove moisture and contaminants from the refrigerant. Excess moisture can damage compressor components and lead to costly repairs. According to a report by the Air Conditioning Contractors of America, 90% of system failures are due to moisture contamination. Using a filter drier can significantly reduce this risk.

These devices work by absorbing water and trapping debris. With clean refrigerant, the system operates more efficiently. Reports indicate that HVAC systems can lose up to 20% efficiency when contaminants are present. A filter drier minimizes pressure drops and strain on the compressor. Still, not all driers are created equal, and periodic checks are needed to ensure proper function.

However, neglecting the maintenance of AC filter driers is common. Many technicians overlook this crucial component during routine service calls. This neglect can result in reduced system performance and higher energy bills. In fact, a study found that regular inspection of filter driers could improve system efficiency by 15%. Keeping driers clean and functional is essential for optimal HVAC operation.

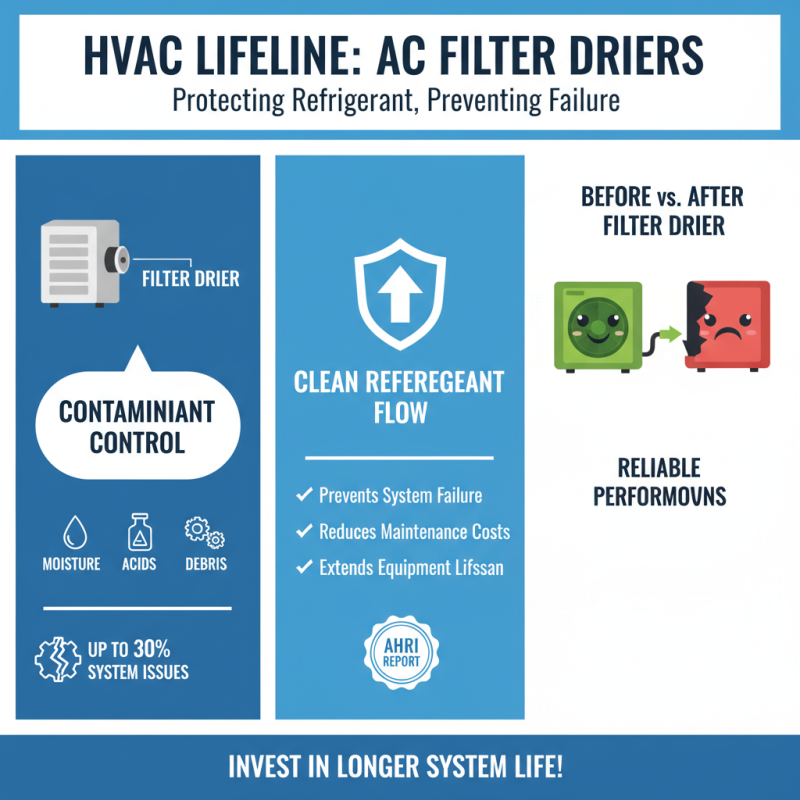

Using AC filter driers in HVAC systems is essential for refrigerant contamination control. Contaminated refrigerants can lead to system failure and increased maintenance costs. According to a report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), up to 30% of HVAC system issues are caused by contaminants in refrigerants. This includes moisture, acids, and debris.

AC filter driers perform a crucial role in filtering out these harmful particles. They trap moisture, which can corrode metal components and create ice. In fact, studies show that moisture can reduce system efficiency by up to 25%. Without proper filtration, the refrigerant loses its effectiveness, leading to higher energy bills and potential breakdowns. It's alarming to note that many systems lack adequate filtration, leaving them vulnerable to damage.

Incorporating an AC filter drier can also improve system lifespan. When contaminants are removed, the compressor operates smoothly, reducing wear and tear. However, many HVAC professionals overlook the importance of regular maintenance and drier replacement. It's essential to remember that neglecting these components can lead to significant long-term costs. Investing in the right filtration can prevent future headaches but requires a commitment to ongoing upkeep.

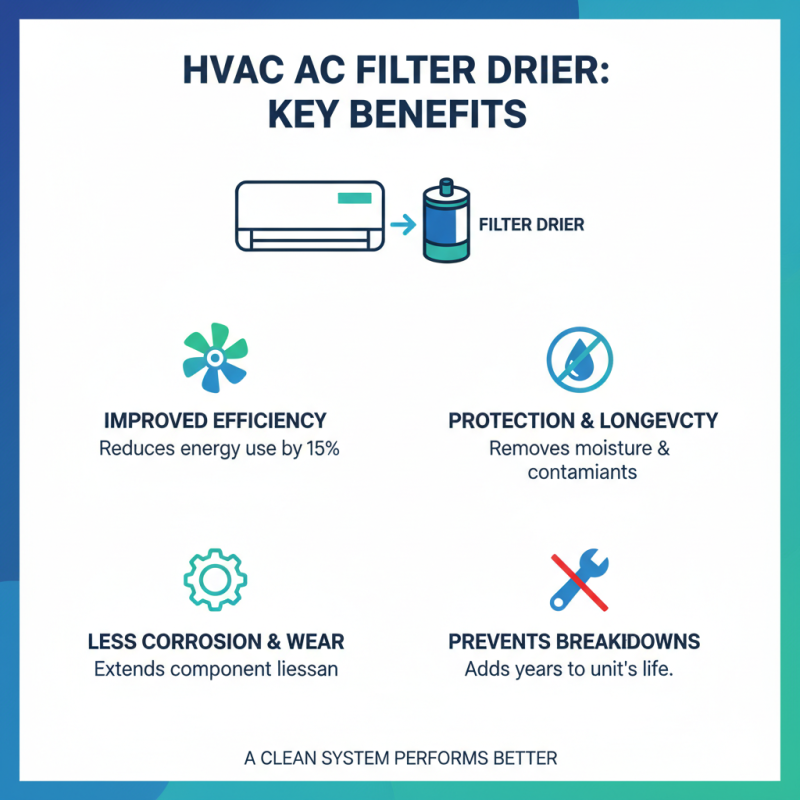

In HVAC systems, using an AC filter drier is crucial for performance and longevity. A clean system runs efficiently, reducing energy consumption by up to 15%. The AC filter drier traps moisture and contaminants. This reduces corrosion and wear on components. Systems without proper filtration may suffer breakdowns. Such failures can decrease the lifespan of the unit by years.

Studies suggest that systems with filter driers have a 25% lower chance of early failure. The contaminants can lead to compressor damage. Such repairs can be costly and time-consuming. Investing in quality filtration minimizes these risks. Proper maintenance ensures sustained performance.

Tips: Change filter driers regularly. Monitor pressure levels often. This simple action can save you from bigger repair costs later. Ensure that the filter drier is compatible with your system. Incompatible parts can lead to suboptimal performance. Without proper filtration, the system may face challenges down the line. Consider these factors carefully during maintenance.

When installing AC filter driers in HVAC systems, consider a few crucial tips. First, ensure the correct size of the filter drier. An oversize unit may not effectively remove contaminants. In contrast, a smaller unit can clog easily. According to the Air Conditioning Contractors of America (ACCA), choosing the right size can enhance system efficiency by up to 15%.

Placement matters too. Install the filter drier in a location that minimizes line length. This helps reduce pressure drops. Too long of a line can lead to increased energy consumption. Also, check for proper orientation during installation. Some driers work best in a vertical position. Misinstallation can lead to poor performance.

Another aspect often overlooked is regular maintenance. Replace AC filter driers every one to three years. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that neglecting this can decrease system efficiency by 20%. Keep track of usage and environmental conditions that may affect the filter drier's lifespan. Regular checks can identify issues early and prevent costly repairs later.

| Benefit | Description | Installation Tips |

|---|---|---|

| Improved Efficiency | AC filter driers enhance system efficiency by removing moisture and contaminants. | Ensure proper sizing of the drier for optimal performance. |

| Prevention of System Damage | Filtering out debris helps prevent compressor and evaporator damage. | Install in line with the refrigerant flow for maximum effect. |

| Longer Equipment Lifespan | Regular use of driers can extend the life of HVAC components. | Replace driers regularly during maintenance to maintain performance. |

| Better Air Quality | Helps in delivering clean air by filtering out harmful particles. | Position the drier strategically within the system for optimal air flow. |

| Reduced Energy Bills | A more efficient system leads to lower energy consumption. | Check for leaks before installation to prevent energy loss. |