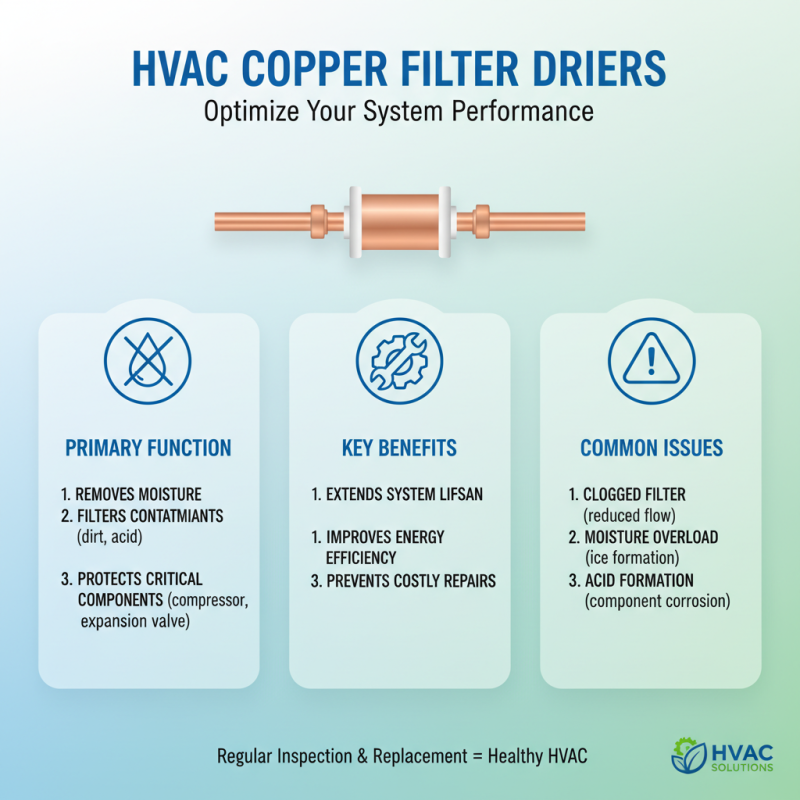

In HVAC systems, the effectiveness of refrigeration relies significantly on the quality of components used. One critical component is the Copper Filter Drier. This device plays a vital role in removing moisture and impurities, thus ensuring better system performance. According to industry reports, proper filtration can increase system efficiency by up to 25%.

The choice of Copper Filter Drier can make or break the longevity of HVAC systems. A report from the International Refrigeration Institute indicates that nearly 30% of system failures can be traced back to inadequate filtration. Therefore, investing in the right product is essential. However, not all Copper Filter Driers are created equal, and options vary widely in performance and durability.

Some users may overlook the necessity of robust filters, thinking all perform similarly. This perception is misleading and can lead to costly repairs or replacements. Selecting the appropriate Copper Filter Drier requires careful consideration and understanding of specific system needs. After all, the right filter not only enhances performance but also extends the overall life of the HVAC system.

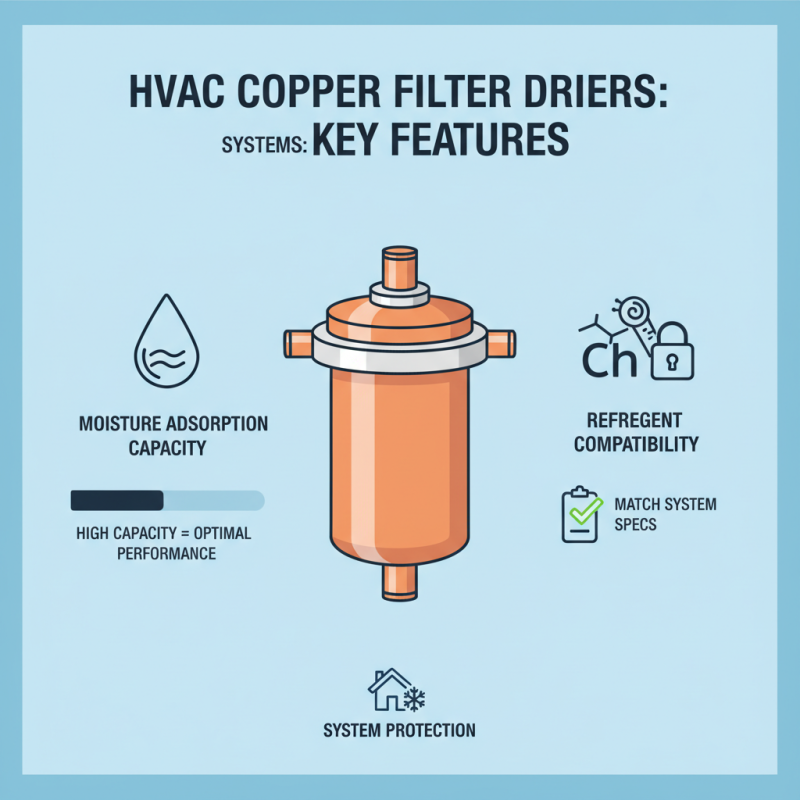

When selecting copper filter driers for HVAC systems, several key features should guide your choice. First, consider the moisture adsorption capacity. This determines how effectively a drier can protect your system from moisture-related issues. A high capacity is essential for optimal performance. Additionally, check the compatibility with refrigerants. Some driers may not work well with certain refrigerants. It's crucial to match the drier with your HVAC system's specifications.

Tips: Always verify the specifications before purchase. A mismatched filter can lead to inefficiency.

Another vital feature is the size and connection type. Ensure the drier fits well within the system. A poorly fitted drier can cause leaks or reduce performance. Also, think about the design. Some designs are easier to install and service than others. An accessible design can save time and effort when maintenance is required.

Tips: Measure your space carefully. Don't rush through this step; even minor discrepancies can create problems.

When it comes to choosing copper filter driers, the options are diverse. Many brands emphasize efficiency and durability, yet their performance can vary significantly. A good filter drier should enhance HVAC systems, providing both reliable moisture control and solid filtration. Some products stand out for their innovative designs. However, other models may not deliver promised results. Evaluating customer reviews may help identify potential issues with certain brands.

In the competitive HVAC market, users often highlight quality and value. Some products are easy to install while others pose challenges. Observing performance in real-world scenarios is essential. A unit that works well in one setting may struggle in another. Not all copper filter driers are created equal. Their effectiveness can depend on various factors such as system type and environmental conditions. It’s important to weigh these factors carefully when making a decision.

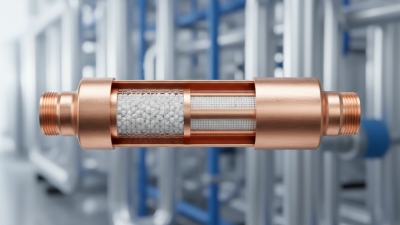

When installing copper filter driers in HVAC systems, proper techniques can significantly enhance efficiency. Research indicates that nearly 40% of energy loss in HVAC systems can be attributed to poor installation practices. Start by ensuring you use the right size filter drier for your system. An oversized unit can lead to increased pressure drops, while an undersized one may not adequately remove moisture.

It's crucial to maintain clean connections during installation. Contamination can lead to system failure or reduced performance. The Air Conditioning Contractors of America suggests that technicians wear gloves and handle components carefully. This helps prevent debris from entering the system. Moreover, always check the manufacturer's guidelines for specific requirements.

Another important factor is the orientation of the filter drier. Installing it vertically or horizontally can affect its performance. Data shows that improperly oriented driers can hinder refrigerant flow, leading to inefficient operation. Regular maintenance should not be overlooked. Yearly checks are vital. This not only prolongs the life of the filter drier but also enhances overall HVAC performance. Attention to these details can make a substantial difference in efficiency and reliability.

This chart presents the performance metrics of various copper filter drier options for optimal HVAC systems in 2026. It illustrates key factors such as capacity, efficiency, price, durability, and installation time that are essential for making informed decisions in HVAC system design and installation.

Copper filter driers play a crucial role in HVAC systems. They help manage moisture and contaminants in refrigeration systems. Proper maintenance practices can significantly enhance their longevity and performance. Regular inspection should be a routine. Check for signs of wear or blockages every six months. According to industry data, systems that are well-maintained can improve efficiency by up to 15%.

Tips: Monitor the refrigerant levels. Low levels can indicate a leak, affecting the filter drier’s performance. Ensure the system is operating within the recommended temperature range. This prevents excessive strain on the components.

Frequent replacement of the drier is necessary when systems undergo repairs or major maintenance. A drier should be replaced whenever the compressor is changed. Neglecting this can lead to poor system performance or even failures. Remember, the filter drier can only function optimally if properly maintained. Regular maintenance is an investment that pays off in the long run.

Copper filter driers are essential for maintaining HVAC systems. They remove moisture and contaminants from refrigerants. Understanding common issues can help improve their performance.

One common problem is clogging. When filters become saturated, they lose efficiency. This can lead to increased pressure in the system. A noticeable drop in cooling performance often follows. Regular maintenance is key. Check filters frequently and replace them as needed.

Another issue is the reaction to various chemicals. Copper can corrode when exposed to certain substances. This can cause leakage and further contamination. It’s crucial to ensure that the refrigerant used is compatible with copper components.

Tips: Always monitor your HVAC system. Look for odd sounds or fluctuating temperatures. These can indicate a problem. Consider using a high-quality filter drier to enhance performance. Regular checks can prevent larger issues in the future. Be proactive to ensure optimal operation.