In the world of refrigeration, choosing the right components is crucial. Refrigeration Copper Fittings play a vital role in ensuring system efficiency and reliability. These fittings connect various elements, creating a seamless flow of refrigerants. A high-quality fitting can prevent leaks and maintain optimal performance.

In 2026, the market offers a wide range of Refrigeration Copper Fittings. However, not all options are equal. Some products lack durability and may fail under pressure. It's essential to find reliable suppliers who prioritize quality. Investing in these fittings can lead to long-term savings. Yet, many overlook this critical aspect during installation.

Choosing the best Refrigeration Copper Fittings requires careful consideration. Look for features such as corrosion resistance and size compatibility. Understanding the specific needs of your cooling system is key. Many individuals make mistakes by rushing this decision. Proper research can make a significant difference in performance and longevity.

Refrigeration copper fittings play a crucial role in HVAC systems. They connect components like compressors, condensers, and evaporators. These fittings ensure that refrigerants flow smoothly. Without them, efficiency drops significantly. Various shapes and sizes are available, including elbows, tees, and couplings. Choosing the right fitting is essential for optimal performance.

The installation of copper fittings requires precision and care. Even a small mistake can lead to leaks. Leaks not only waste refrigerant but also reduce the system's efficiency. It’s important to consider factors like pressure ratings and operating temperatures. Improper selections can result in costly repairs later.

Maintenance is another critical aspect to keep in mind. Regular checks can prevent hidden issues. Sometimes, signs of wear might not be evident until leaks occur. Being proactive can save time and money. Understanding the unique requirements of your system is key. Copper fittings might seem simple, yet their impact is profound. Your cooling system deserves attention to detail.

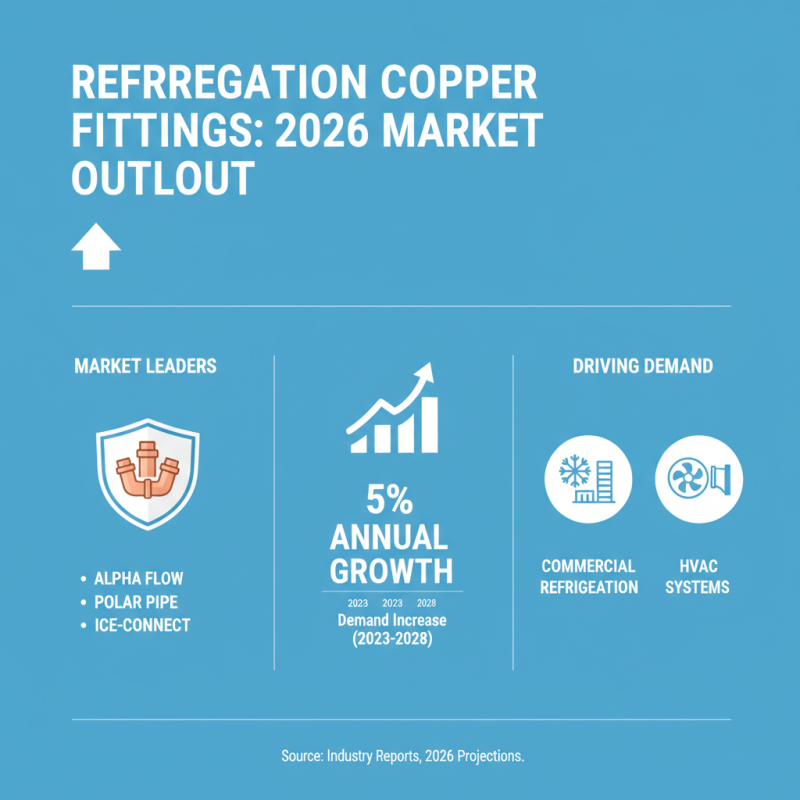

This chart illustrates the estimated market share of various types of refrigeration copper fittings used in HVAC systems as of 2026. It highlights the demand for different fitting sizes, which play a crucial role in ensuring efficient cooling across various applications.

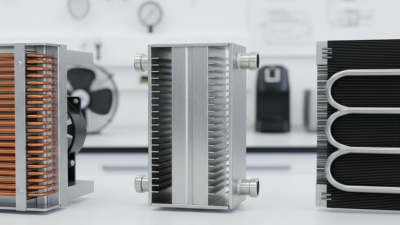

When selecting copper fittings for refrigeration, pay attention to multiple key features. The material grade is crucial. Look for high-purity copper that can withstand low temperatures and resist corrosion. Durability ensures longevity; low-quality fittings may leak or break over time. Choose fittings that guarantee a tight seal to prevent refrigerant loss.

Gauge the size and compatibility of the fittings with your system. Proper dimensions ensure an efficient flow of refrigerants. Check the thickness as well; thicker walls usually provide better performance. Additionally, consider the joint type. Soldered joints can sometimes fail if not done correctly. Achieving a perfect solder can be tricky. Practice makes perfect here.

Lastly, examine the finish of the fittings. A polished surface reduces friction, promoting better efficiency. However, some fittings might have imperfections. These can lead to unexpected issues. It's essential to inspect all options thoroughly. Quality control can vary. Taking time to understand each option improves your selection process.

| Type | Pipe Size (inches) | Max Pressure (psi) | Temperature Range (°F) | Material Grade |

|---|---|---|---|---|

| Coupling | 1/2 | 500 | -40 to 250 | C12200 |

| Elbow | 3/4 | 600 | -40 to 250 | C12300 |

| Tee | 1 | 700 | -40 to 225 | C12000 |

| Reducer | 1/2 - 3/4 | 550 | -40 to 250 | C12200 |

| Cap | 3/4 | 500 | -40 to 250 | C12300 |

In the competitive landscape of refrigeration copper fittings for 2026, several brands stand out as market leaders. According to industry reports, the demand for high-quality copper fittings is projected to grow annually by 5% from 2023 to 2028. This growth reflects the increasing need for efficient cooling solutions across various sectors, including commercial refrigeration and HVAC systems.

Leading manufacturers are focusing on enhancing product performance. Innovations in manufacturing processes have resulted in more durable and corrosion-resistant copper fittings. However, it's important to note that not all brands maintain consistent quality. Reports indicate that 15% of copper fittings may fail under extreme conditions. Users should carefully assess product specifications to select reliable fittings for their specific applications.

As the market evolves, sustainability has become a key concern. Companies are investing in eco-friendly practices, but the transition isn't flawless. A recent study highlighted that only 40% of manufacturers currently use recycled copper. This raises questions about environmental responsibility among competitors. Consumers are encouraged to prioritize brands that demonstrate a commitment to sustainable practices.

When selecting copper refrigeration fittings, adherence to industry standards is crucial. These standards ensure quality, safety, and efficiency. Organizations like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) publish guidelines for copper fittings. A 2020 ASHRAE report emphasized that using certified fittings reduces leaks by nearly 30%. This data highlights the importance of reliable components in refrigeration systems.

Certifications such as ASTM and ISO add layers of trust. They assess the materials and manufacturing processes. In 2021, studies showed that poorly manufactured fittings account for about 15% of system failures. These failures often stem from inadequate testing or lack of certification. Investing in certified copper fittings can minimize risks.

Choosing the right fittings involves more than just compliance. Understanding the specific requirements of your cooling system is vital. Not all copper fittings are created equal. For instance, the wall thickness and joint type can significantly affect performance. Manufacturers often overlook these details, leading to inefficiencies. It’s essential to evaluate your options carefully.

Copper fittings are evolving. Recent trends show a shift towards higher efficiency and improved performance. Industry reports reveal that over 80% of HVAC professionals prioritize energy-efficient solutions. Using advanced welding techniques, manufacturers are creating stronger joints. This leads to fewer leaks and reduced energy loss.

The integration of smart technologies is another significant trend. Smart monitoring systems can detect changes in pressure and flow rates. This proactive approach minimizes downtime and extends equipment lifespan. According to a study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), smart fittings can save up to 20% in operational costs.

However, challenges remain. Some professionals report difficulties in adapting to new standards. Training is necessary for effective implementation. Innovations also come at a cost. Budget constraints may limit access to cutting-edge solutions for smaller companies. Balancing costs with performance will be crucial for the future of copper fittings in HVAC systems.