Choosing the right Liquid Line Filter Drier is crucial for your HVAC system. A suitable filter drier enhances system efficiency. It also reduces the risk of damage over time.

Maintaining your Liquid Line Filter Drier is equally important. Regular inspections can identify issues early. These may seem like minor details, yet neglecting them could lead to significant problems.

Consider factors such as the size and type of your system. Not all filter driers are created equal. Finding the perfect fit may take time and research. Remember, even small oversights in this choice can affect performance. It's a reminder that detail matters in HVAC maintenance.

A liquid line filter drier plays a crucial role in HVAC systems. It removes moisture and contaminants from the refrigerant, ensuring efficient operation. According to industry reports, moisture can decrease system reliability by up to 40%. This moisture can lead to corrosion and damage, ultimately shortening system life.

Installing a filter drier can prevent costly repairs. It acts as a barrier against debris that could clog the system. A clean system runs more efficiently, saving energy. However, choosing the right size and type is vital. Oversized or undersized filter driers may not function well. It can be hard to gauge the right fit without experience.

Tip: Check the manufacturer’s specifications for your system’s requirements. Regular maintenance is essential. Change or clean the filter drier periodically to avoid blockages. Failing to do this can miss hidden issues. Moreover, don't overlook the installation process. Improper installation can lead to leaks, negating the benefits of the drier. Keep an eye on performance metrics. Small changes in efficiency can indicate problems.

This chart represents key performance metrics for liquid line filter driers, including efficiency, pressure drop, temperature, and capacity. Understanding these metrics helps in choosing and maintaining the right filter drier for your system.

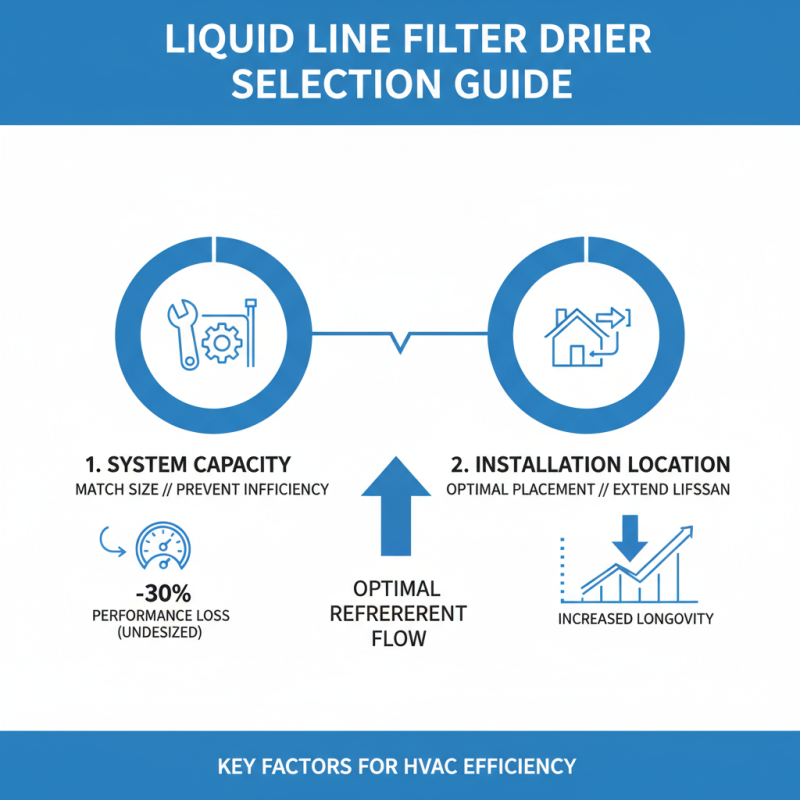

When selecting a liquid line filter drier, several factors deserve attention. Size is critical. The drier must match the system capacity. A mismatch may lead to inefficiency. According to industry data, undersized units can reduce performance by up to 30%. Proper sizing ensures optimal refrigerant flow. The location of installation also matters. A unit placed incorrectly can reduce its lifespan.

Next, consider the type of filter media. Some materials might handle moisture better than others. For example, desiccant driers perform well in high humidity environments. Reports show that they can absorb moisture quickly. This characteristic helps maintain system integrity. Another crucial factor is the pressure rating of the drier. Ensure it meets or exceeds system pressure. Low ratings can lead to failure, causing expensive repairs.

Don't ignore the refrigerant type your system uses. Some filter driers may not be compatible with all refrigerants. Using an incompatible product can result in inadequate filtration or even damage. It’s essential to consult the manufacturer's specifications. Each system is unique. Making informed choices can avoid costly repercussions down the line.

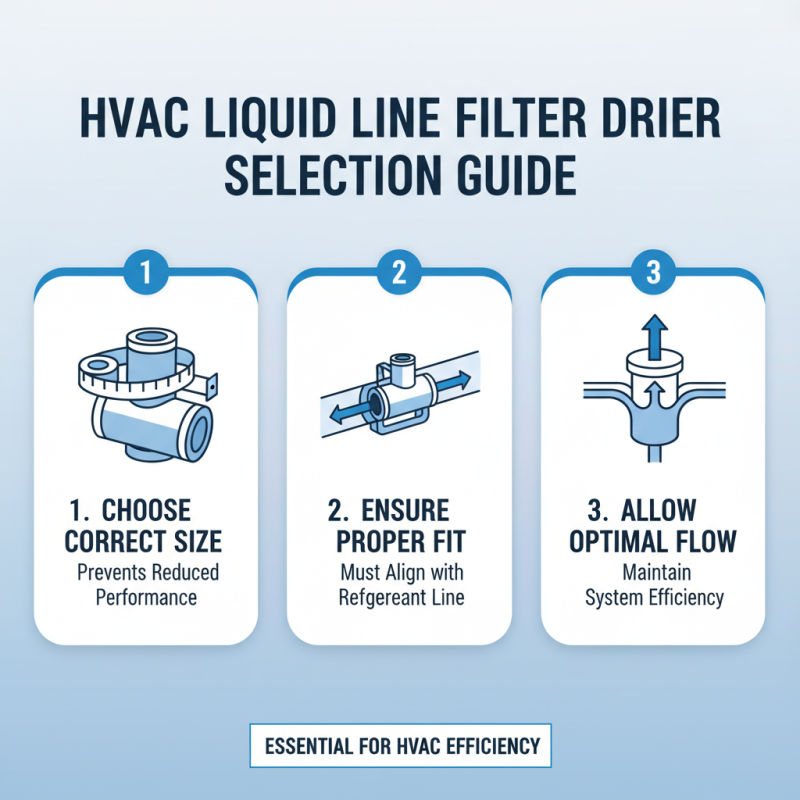

Installing a liquid line filter drier is essential for the efficiency of your HVAC system. Start by selecting the right size for your system. An oversized drier may lead to reduced performance. Ensure it fits within the refrigerant line and allows for proper flow.

Before installation, gather all necessary tools. You will need a pipe cutter, wrenches, and soldering equipment. Cut the refrigerant line carefully, making sure to minimize any debris that could enter the system. Clean the edges thoroughly before attaching the drier.

When installing, make sure the flow direction matches the arrows on the drier. A backward installation can cause major issues. After positioning, secure it properly, and be cautious while soldering to avoid overheating.

Tips: Always wear safety gear. A small mistake can lead to leaks. Double-check connections before starting your system. Look for any signs of refrigerant leaks after installation. Pulling a vacuum on the system is crucial to remove any moisture and contaminants. This step cannot be overlooked.

Maintaining a liquid line filter drier is crucial for HVAC efficiency. Regular checks can prevent system failures. According to the Air-Conditioning, Heating, and Refrigeration Institute, proper maintenance can enhance system reliability by 30%. Keeping the filter drier clean ensures optimal refrigerant flow.

Tips: Inspect your drier monthly. Look for dirt or debris that could hinder functionality. Replace the filter drier every 1 to 2 years, depending on system usage. A neglected filter can lead to compressor damage and lower efficiency.

Routine maintenance should include checking for leaks. Leaks can reduce refrigerant levels and efficiency. Use a leak detection solution to pinpoint issues. Even small leaks can become major problems if ignored. Monitoring operating pressures regularly is also essential. Deviations from normal pressure can indicate drier problems. Schedule maintenance visits from professionals if unusual readings persist.

Tips: Keep a maintenance log. Document when filters are changed or checked. This will help track patterns over time. Regular attention to these details can save money in the long run. Investing time in routine checks prevents costly repairs down the road.

When it comes to maintaining your HVAC system, recognizing signs that indicate it's time to replace your liquid line filter drier is crucial. A report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers states that 50% of system failures are linked to improper filtration. If your unit is experiencing fluctuating temperatures or reduced efficiency, it may be time to check the filter drier.

Another important sign is moisture accumulation. A study from the U.S. Department of Energy suggests that even small amounts of moisture can lead to corrosion. If you notice ice formation on the evaporator coil, it’s a clear indicator of a malfunctioning filter drier. This can affect your system's overall performance and lead to costly repairs.

Clogs can also signal the need for replacement. If debris builds up, pressure can increase in the system. According to industry analyses, this can create unwanted strain on components, leading to premature failure. At this point, replacing the filter drier becomes imperative to ensure system longevity and efficiency. Regular checks and timely replacements can save you from unexpected breakdowns. These small yet critical interventions can significantly impact the lifespan and performance of your HVAC system.

| Dimension | Details |

|---|---|

| Filter Drier Type | Liquid Line, Suction Line |

| Filtration Level | 10 micron, 20 micron |

| Refrigerant Compatibility | R-410A, R-22, R-134A |

| Signs of Replacement | Reduced efficiency, System pressure increase, Frequent system shutdowns |

| Maintenance Tips | Regular inspection, Replace every 1-3 years, Clean condensate lines |

| Installation Considerations | Location, Pipe size, Flow direction |