In the realm of HVAC systems, maintaining optimal performance and efficiency is paramount. One of the key components that play a critical role in this process is the Aluminum Filter Drier. This device not only aids in the filtration of contaminants but also serves to manage moisture levels within the refrigeration cycle, ensuring that the system operates smoothly and reliably. As we approach 2025, the selection of the right Aluminum Filter Drier has become increasingly important, given the advancements in HVAC technology and the growing emphasis on sustainability.

Choosing the appropriate Aluminum Filter Drier requires careful consideration of several factors, including system compatibility, size, and performance specifications. As HVAC systems evolve, the necessity for components that enhance energy efficiency and prolong system lifespan becomes more pronounced. Understanding how to evaluate these factors will empower technicians and homeowners alike to make informed decisions that not only improve the effectiveness of their HVAC systems but also bolster environmental responsibility.

In this guide, we will explore the essential criteria that should influence your choice of an Aluminum Filter Drier, equipping you with the knowledge to optimize your HVAC setup as we move forward into a new era of climate control technologies.

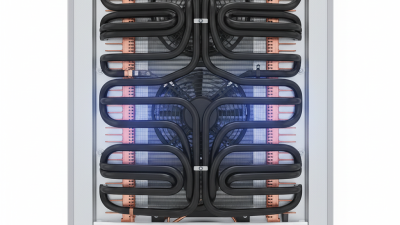

Aluminum filter driers play a crucial role in the efficiency and longevity of HVAC systems. They are designed to remove moisture and contaminants from the refrigerant circulating within the system, which is essential for maintaining optimal performance. In HVAC applications, excess moisture can lead to complications such as refrigerant degradation, corrosion of components, and ice formation in evaporators. The aluminum construction of these filter driers allows for effective filtration without compromising the weight or structural integrity, making them an increasingly popular choice for both residential and commercial systems.

Understanding the specific functions of aluminum filter driers can help HVAC professionals make informed decisions about their installation and maintenance. Filter driers not only capture particulates and contaminants but also serve to protect the compressor from liquid refrigerant slugging. By absorbing moisture, they help maintain the integrity of the refrigerant, ensuring that the system operates efficiently and reducing the risk of costly repairs. Selecting the right aluminum filter drier involves considering factors such as system size, refrigerant type, and environmental conditions, which can significantly impact overall HVAC system performance.

When selecting an aluminum filter drier for your HVAC system, several key factors come into play. First and foremost, you must consider the capacity of the drier, which should match the cooling capacity of your system. This ensures that the filter drier can effectively remove moisture, particulates, and contaminants from the refrigerant without impairing system performance. A proper match not only enhances efficiency but also extends the longevity of your HVAC components.

Another crucial factor to contemplate is the operating temperature and pressure range of the drier. An aluminum filter drier must be suitable for the specific refrigerant used within your HVAC system, as different refrigerants operate under varying conditions. Pay close attention to the specifications provided for the drier to ensure its compatibility and effectiveness. Furthermore, the absorption capacity of the drier should also be considered, as it determines how much moisture and contaminants it can handle before needing replacement. Choosing a drier with an appropriate absorption capacity helps maintain optimal system functionality and reliability.

When selecting an aluminum filter drier for your HVAC system, understanding the different types available is essential for optimizing system efficiency. Aluminum filter driers are crucial for removing moisture and contaminants from refrigerants, which can prolong the lifespan of the HVAC system and maintain its performance. The primary types of aluminum filter driers include standard, bi-flow, and dedicated liquid line filter driers. Each type offers distinct advantages based on the specific needs of your system.

Standard aluminum filter driers are commonly used in conventional HVAC applications and excel in environments with consistent refrigerant flow. In contrast, bi-flow filter driers are designed for heat pump systems, facilitating refrigerant flow in both directions, which is vital for heat exchange during seasonal changes. Dedicated liquid line filter driers are optimized for refrigerant lines that handle liquid only, effectively maintaining a high level of filtration and ensuring that the system operates efficiently, even under varying load conditions.

When evaluating these options, consider factors such as refrigerant type, system capacity, and installation requirements. Selecting the appropriate filter drier not only enhances the system's energy efficiency but also contributes to its overall reliability and longevity. By comparing the functionalities and applications of each type, you can make an informed decision tailored to your HVAC system's specific demands.

When installing an aluminum filter drier for your HVAC system, proper placement is essential to maximize its performance. Ideally, the filter drier should be installed in the liquid line, immediately after the condenser, to effectively catch any moisture and contaminants before they enter the evaporator. Ensuring that the filter drier is positioned upright will help in maximizing the flow of refrigerant, which is crucial for maintaining system efficiency.

Moreover, pay close attention to the sealing of connections during installation. Leaks can lead to reduced performance and costly repairs, so using proper fittings and ensuring a leak-free environment is critical. It's also advisable to check the manufacturer's recommendations regarding the size and type of filter drier appropriate for your system. Installing a filter drier that is too large or too small can severely impact the HVAC system's efficiency. Regular maintenance checks should be scheduled to monitor the condition of the filter drier, ensuring it continues to operate at peak performance throughout its lifespan.

Proper maintenance of your aluminum filter drier is essential to ensure the longevity and efficiency of your HVAC system. Regular inspections should be prioritized, as it has been found that nearly 30% of HVAC failures can be traced back to inadequate maintenance of components like filter driers. These critical parts are designed to remove moisture and contaminants from the refrigerant, but if not maintained properly, they can become clogged or compromised, leading to increased energy consumption and potential system breakdowns.

To extend the life of your aluminum filter drier, it is recommended to perform routine checks every six months, especially in systems operating under high humidity or variable load conditions. Additionally, it is beneficial to replace the filter drier every two to five years, depending on system usage and environmental factors. Research indicates that a well-maintained filter drier can enhance system efficiency by as much as 10-15%, translating into significant cost savings on energy bills. Implementing proactive measures, such as monitoring pressure drops and refrigerant levels, will help to safeguard the operational integrity of your HVAC system and maximize the lifespan of the filter drier.

This chart illustrates key metrics to consider when selecting an aluminum filter drier for your HVAC system, including capacity, maintenance frequency, average cost, and lifespan. Understanding these factors is essential for effective maintenance practices that extend the life of your aluminum filter drier.