When it comes to maintaining the efficiency and longevity of HVAC systems, selecting the appropriate Recovery Filter Drier is crucial. These components play a vital role in filtering out impurities and moisture from refrigerants, ensuring optimal system performance. However, with a myriad of options available on the market, choosing the right Recovery Filter Drier can be a daunting task.

In this article, we present the top 10 tips designed to guide you through the selection process. These tips will help you understand what to consider regarding your specific system requirements, the types of refrigerants used, and the unique challenges your system may face. By equipping yourself with the right knowledge, you can make a well-informed decision that will not only enhance the efficiency of your HVAC system but also prevent costly breakdowns and repairs in the future. Whether you are a seasoned technician or a novice in the industry, following these guidelines will ensure you select the most suitable Recovery Filter Drier for your needs.

Recovery filter driers play a crucial role in maintaining the efficiency and longevity of HVAC systems. These components are responsible for removing moisture, acidity, and particulate matter from refrigerants, which helps prevent corrosion and equipment failure. In the journey of refrigerant recovery, filter driers ensure that the substance being recycled is clean and dry, ultimately leading to improved system performance and reliability. By filtering out contaminants, these devices protect the critical components of the HVAC system, allowing for smoother operations and reduced risk of breakdowns.

Selecting the right recovery filter drier is essential for optimizing HVAC functionality. Factors such as system capacity, refrigerant type, and operating conditions must be considered to ensure compatibility and effectiveness. A correctly chosen filter drier not only enhances refrigerant recovery processes but also extends the overall lifespan of HVAC systems. HVAC professionals should assess their specific needs and the environmental conditions in which the systems operate, as these elements influence the choice of filter drier significantly. Ultimately, understanding the role and functionality of recovery filter driers can lead to more informed decisions, resulting in better HVAC performance and efficiency.

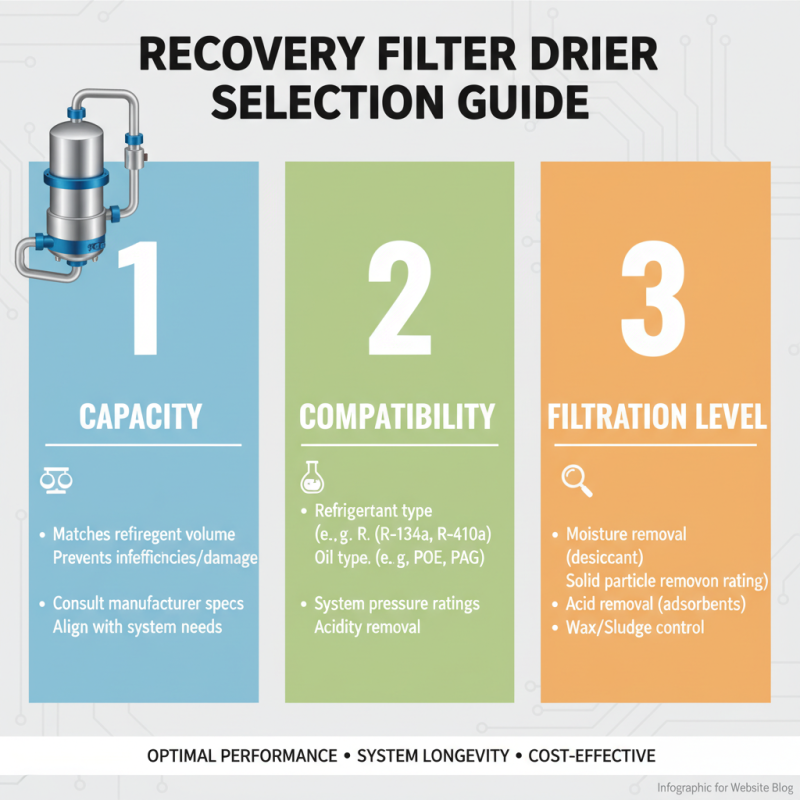

When selecting the right recovery filter drier, several key factors must be taken into account to ensure optimal performance and compatibility with your system. First, consider the capacity of the drier, which is crucial for effectively handling the volume of refrigerant in your applications. A drier that is too small can result in system inefficiencies and potential damage, while one that is oversized may lead to unnecessary costs. Assessing the manufacturer's specifications alongside your specific requirements will help you identify the most suitable capacity.

Another important aspect is the type of refrigerant the filter drier will be used with. Different types of refrigerants have distinct properties that can affect the performance of the recovery filter drier. Ensure that the selected drier is compatible with the refrigerant type to avoid potential breakdowns and enhance the overall longevity of the system. Additionally, the compatibility of materials should be verified, as certain filter driers may not work well with specific oils or contaminants. Taking these factors into account will significantly improve your chances of selecting a recovery filter drier that meets your needs effectively.

When selecting a recovery filter drier, it's essential to understand the various types available and their specific applications. There are typically three main categories of recovery filter driers: traditional, compact, and molecular sieve types. Traditional filter driers are designed to remove moisture and impurities from refrigerants, making them ideal for conventional refrigeration and air conditioning systems. These units typically use a combination of filtration media to ensure that the refrigerant remains clean and dry, which is crucial for maintaining system efficiency and longevity.

Compact filter driers, on the other hand, are tailored for space-constrained applications. These driers incorporate a compact design that doesn't compromise on performance, making them suitable for residential HVAC systems and smaller commercial installations. Their reduced size allows for easier installation in tight spaces while still providing effective moisture removal to protect the system from corrosion and blockages.

Lastly, molecular sieve driers are specifically engineered to handle low-temperature refrigerants and applications where absolute moisture removal is critical. These driers utilize advanced filtration technology to capture water molecules effectively, offering superior performance in environments prone to humidity issues. They are commonly used in refrigeration systems that operate at critical low temperatures or in specialized applications such as food processing and pharmaceuticals, where maintaining the integrity of the refrigerant is paramount. Understanding these types and their applications is key to choosing the right recovery filter drier for your specific needs.

When selecting a recovery filter drier, it is essential to evaluate specific specifications that align with your needs. One of the most critical factors to consider is the flow rate. A filter drier should accommodate the volume of refrigerant being processed without causing excessive pressure drop. This ensures efficient recovery while maintaining system integrity.

Additionally, check for compatibility with the refrigerants you are using, as filter driers are made with materials suited for different types of fluids.

Another important specification is the moisture removal capacity. The ability of a recovery filter drier to remove moisture is vital, as excessive moisture can lead to corrosion and system inefficiencies. Look for driers with high moisture absorption rates and those that offer adequate filtration to capture particulate contaminants. Also, consider the physical dimensions and connection types to ensure the filter drier fits seamlessly within your existing system configuration. By focusing on these specifications, you can make an informed decision that enhances the reliability and efficiency of your refrigeration system.

Proper maintenance of recovery filter driers is essential for ensuring their optimal performance and longevity. Regularly checking and replacing the filter drier can prevent system clogging and maintain efficient refrigerant flow. It's vital to inspect connections and fittings for any signs of leaks or wear, as even small leaks can compromise performance and efficiency. Additionally, keeping the unit clean from debris and dust will help in reducing strain on the system, ensuring it operates at peak efficiency.

Another critical tip is to monitor the temperature and pressure levels of the system. Maintaining these within the manufacturer's recommended ranges will not only prolong the life of your recovery filter drier but also enhance the entire refrigeration system’s performance. If you notice any irregularities, it is important to address them immediately to avoid significant damage.

Lastly, ensure that you are using the appropriate filter drier for your specific needs, as this greatly impacts the efficiency of your recovery process. Regular training and updates on best practices in maintenance can further enhance your understanding of operational efficiency and help in preventing potential issues before they arise.

This bar chart illustrates the importance levels of various criteria to consider when choosing the right recovery filter drier, ranging from capacity to brand reputation. The values represent how critical each factor is, on a scale of 1 to 10, aiding in making an informed decision for optimal performance.