Choosing the right Recovery Filter Drier is crucial for an efficient HVAC system. Many professionals emphasize its importance. According to the HVAC Industry Report 2023, improper selection can lead to system inefficiencies and increased repair costs.

Expert John Smith, a leading figure in HVAC technology, states, "A well-chosen Recovery Filter Drier can enhance system reliability." This highlights the need for careful consideration. An ill-fitting filter can lead to moisture buildup, which is detrimental.

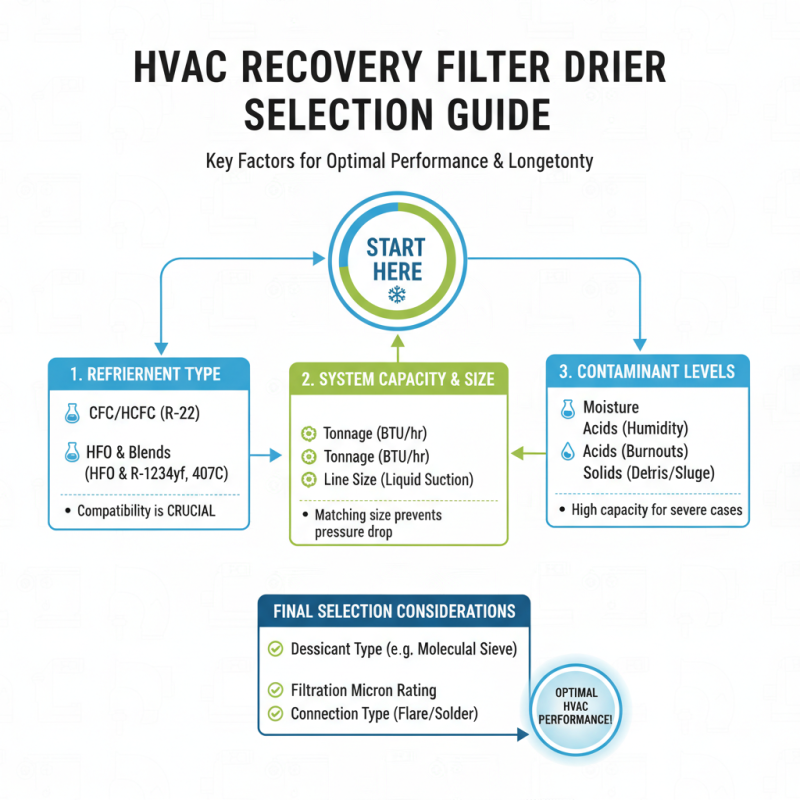

When selecting a Recovery Filter Drier, factors like system size and refrigerant type matter. Many overlook how these choices impact overall performance. A mistake here can result in non-optimal operation, leading to unnecessary expenses. It's clear that the correct choice requires thorough research and understanding of specific requirements in HVAC systems.

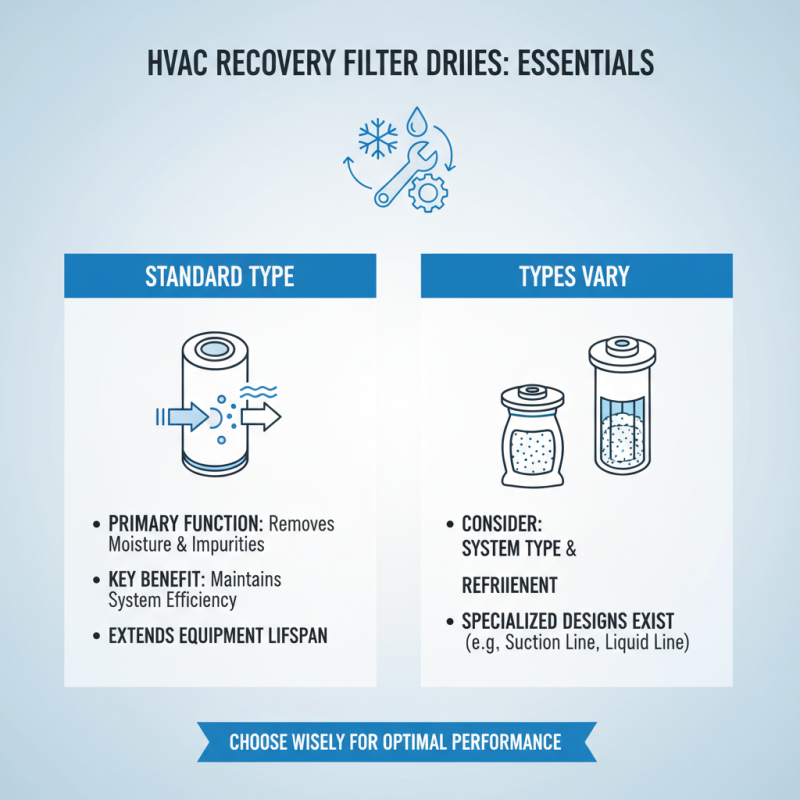

Recovery filter driers play a crucial role in HVAC systems. They help remove moisture and contaminants from refrigerants. Moisture can lead to corrosion and freezing issues. Contaminants may cause wear on vital system components. A good recovery filter drier ensures the longevity of your HVAC equipment.

Choosing the right drier is not always straightforward. There are many types available. Some are suitable for specific refrigerants. Others are more versatile. It's important to consider the system's requirements. The wrong choice may lead to poor performance. This could cost more in repairs and maintenance.

Installation of recovery filter driers requires attention. Incorrect installation can reduce efficiency. Make sure all connections are tight. A proper installation ensures optimal function. Regular checks are necessary to maintain performance. Sometimes, we overlook these small details, which can lead to problems. Regular maintenance keeps your HVAC system running smoothly.

This chart illustrates the recommended filter drier sizes in cubic inches for various types of refrigerants used in HVAC systems. Selecting the appropriate filter drier based on the refrigerant type is crucial for optimal efficiency and reliability of HVAC systems.

Choosing the right recovery filter drier for your HVAC system is critical. Several key factors can influence your decision. Understanding these is essential for effective performance and longevity.

The capacity of the filter drier is crucial. It needs to match the cooling capacity of the system. For instance, a system with a capacity of 30,000 BTU typically requires a drier rated for at least this amount. Filtering efficiency is another important factor. A good filter drier can remove moisture, acids, and debris from the refrigerant. This helps prevent compressor failure, which costs an average of $1,500 to replace.

**Tip:** Check the drier’s micron rating. A lower rating indicates better filtration. This can significantly extend the life of your HVAC system.

Consider the refrigerant type as well. Some driers are compatible with specific refrigerants. According to the Air Conditioning Contractors of America, using the wrong drier can lead to system corrosion and increased maintenance costs.

**Tip:** Always consult the AVC guidelines and manufacturer recommendations for your HVAC needs.

Lastly, installation practices matter. Improper installation can compromise the drier’s function. Be aware that shortcuts may save time but could lead to costly repairs later.

Choosing wisely is essential for the efficiency and health of your HVAC system.

When selecting a recovery filter drier for your HVAC system, it’s essential to understand the types available. A standard recovery filter drier is designed to remove moisture and impurities from refrigerants. This is crucial in maintaining system efficiency and extending its lifespan. However, not all filter driers are alike.

Some models are specifically tailored for different refrigerants. For instance, if your system uses R-410A, you’ll need a compatible filter drier. Other types include bi-flow driers, which work for heat pumps. These driers can handle the directional flow of refrigerant in both heating and cooling modes. It’s important to note that choosing the wrong type can lead to suboptimal performance.

Installation can also be tricky. A poorly installed filter drier may not function correctly. This could lead to unnecessary repairs or replacements. Therefore, take the time to select the right type based on your specific needs. Research can help, but there’s always a learning curve. Embracing mistakes can lead to better choices in the future.

When selecting a recovery filter drier for your HVAC system, it's crucial to examine specific specifications. The filtration capacity is key. A drier should effectively remove moisture and particulates. Look for units with a high micron rating to capture smaller particles. This improves efficiency and prolongs the system's life.

Pay attention to the drier’s pressure rating. It must align with your system's requirements. A mismatch can lead to failures. Also, consider its compatibility with various refrigerants. Not all driers work well with every type. This could lead to unexpected issues down the line. Inadequate research might result in poor performance.

The physical size of the drier also matters. Ensure it fits within your HVAC layout. A compact design may save space but could restrict airflow. Look for a drier that balances size and performance. Remember, a poorly chosen drier can cause more damage than good. Think carefully about each specification before making a purchase. It’s a decision you’ll have to live with.

| Specification | Description | Importance |

|---|---|---|

| Filter Type | Strainer, drier, or combination | Affects moisture removal efficiency |

| Capacity | Measured in tons or BTUs | Ensures the unit can handle system load |

| Pressure Rating | Defines maximum operating pressure | Safety and compatibility with system |

| Refrigerant Compatibility | Compatible with R-410A, R-22, etc. | Prevents damage to the system |

| Port Size | 1/4", 3/8", 1/2", etc. | For correct installation and fit |

| Material | Aluminum, steel, or composite | Durability and corrosion resistance |

| Dimensions | Height, width, and depth specifications | Affects installation space and design |

| Weight | Weight of the unit | Impacts ease of installation |

Proper installation and maintenance of recovery filter driers are crucial for HVAC systems. When setting up a new drier, take care with placement. Ensure it is easy to access but out of the way of potential damage. Make sure that it is positioned correctly in the refrigerant line. The drier should be installed in the liquid line to effectively trap moisture and contaminants. Leaks can often occur at connection points. Using reliable sealing methods can mitigate this problem.

Regular maintenance is equally vital. Schedule routine checks to monitor the drier's condition. Look for signs of wear or clogging. A well-maintained drier can significantly improve system efficiency. Remember to replace the drier when necessary. Over time, filter materials can become saturated. Ignoring this can lead to system inefficiencies. It can also cause serious damage in severe cases.

Listening to your system is also essential. Strange noises or diminished cooling performance may signal a problem. These signs shouldn't be ignored. An ounce of prevention is worth a pound of cure, as they say. Regular recordings of system performance help with this. Keeping a log may reveal patterns or emerging issues. Careful monitoring lays the foundation for a healthy HVAC system.