When it comes to HVAC systems, the selection of components significantly influences the overall efficiency and functionality of the system. Among these components, the Refrigeration Tee plays a critical role in refrigerant distribution and system performance. As a vital connector in piping systems, it facilitates the effective flow of refrigerants, making it imperative for HVAC professionals to choose the right type according to specific requirements. With a myriad of options available, understanding the fundamental aspects of Refrigeration Tees is essential for achieving optimal system performance.

Choosing the appropriate Refrigeration Tee requires a comprehensive understanding of both the technical specifications and the operational demands of your HVAC system. Factors such as the type of refrigerant used, the system's design, and the intended application all contribute to the selection process. By considering these elements, HVAC professionals can ensure that they are making informed decisions that lead to enhanced efficiency, reliability, and longevity of their refrigeration systems. This guide aims to provide a structured approach to selecting Refrigeration Tees that meet specific HVAC needs, ensuring that installations are both effective and compliant with industry standards.

Refrigeration tees play a crucial role in HVAC systems, enabling the efficient distribution of refrigerant throughout various components. Understanding the basic function of refrigeration tees is essential for selecting the right one for your needs. They allow the refrigerant to split into multiple paths, which is vital for systems designed to serve multiple zones or components. These tees can be constructed from different materials, typically copper or plastic, which influences durability and efficiency.

When choosing a refrigeration tee, consider the refrigerant type used in your system. Certain materials are better suited for specific refrigerants, while others may not perform optimally or could be subject to corrosion. Additionally, the size of the tee must match the diameter of the connecting pipes to ensure smooth flow without pressure losses.

**Tips:** Always consult with an HVAC professional to determine the best material and size for your refrigeration tee. Regular maintenance and checks on the tees can prevent leaks and ensure the longevity of your HVAC system. Furthermore, it’s wise to consider the operating temperature and pressure when selecting a refrigeration tee to guarantee compatibility and efficiency. Proper selection and maintenance are key to a reliable and effective HVAC system.

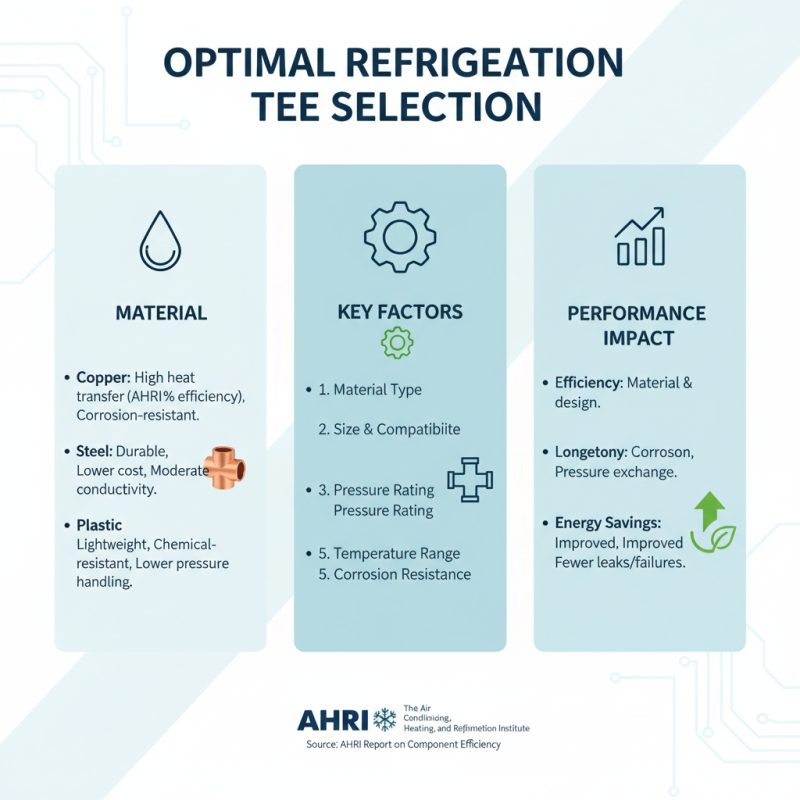

When selecting the right refrigeration tee for your HVAC systems, it's crucial to identify several key factors that directly impact performance and efficiency. Firstly, the material used in the construction of the tee plays a significant role. Common materials include copper, steel, and plastic, each with unique properties that affect thermal conductivity and corrosion resistance. According to a report by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), components made from high-quality copper can improve heat transfer efficiency by up to 30%, thus reducing energy consumption in cooling applications.

Another important consideración is the sizing and pressure rating of the refrigeration tee. Ensuring that the tee matches the specifications of your HVAC system is vital to prevent leaks and maintain optimal functionality. Data from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that incorrect sizing can lead to a decrease in system efficiency, costing businesses approximately 10% more in energy expenses annually. Additionally, evaluating the tee's compatibility with refrigerants is essential, as certain materials may not withstand the chemical properties of modern refrigerants. Selecting the appropriate refrigeration tee can significantly enhance system performance and longevity, ultimately contributing to more sustainable HVAC solutions.

When selecting a refrigeration tee for your HVAC system, it's essential to understand the different types available and their specific applications. Refrigeration tees typically come in various materials, including copper, brass, and plastic, each offering unique benefits. Copper tees are known for their durability and excellent thermal conductivity, making them suitable for high-efficiency systems. Brass tees, while also durable, are often preferred for their resistance to corrosion, making them ideal for environments with varying temperatures and humidity levels. Plastic tees offer lightweight options that are resistant to certain types of chemical exposure, making them suitable for specialized applications.

In addition to the material, the size and connection type of refrigeration tees play a significant role in their compatibility with existing HVAC systems. Common connection types include soldered, threaded, and push-fit options, each providing distinct advantages depending on the installation requirements. For instance, soldered connections are typically more robust and suitable for high-pressure situations, whereas push-fit connections are easier to install and require no special tools, making them user-friendly for quick retrofits. Understanding these differences will help you make an informed choice that aligns with your HVAC needs while ensuring optimal system performance.

| Type of Refrigeration Tee | Material | Size Range (inches) | Max Pressure (psi) | Suitable Applications |

|---|---|---|---|---|

| Copper Refrigeration Tee | Copper | 1/4 - 1 | 300 | Air Conditioning, Refrigeration |

| PVC Refrigeration Tee | PVC | 1/2 - 2 | 150 | Low-pressure systems, Drainage |

| Steel Refrigeration Tee | Carbon Steel | 1 - 6 | 600 | High-pressure systems |

| Brass Refrigeration Tee | Brass | 3/8 - 1 | 400 | Medium-pressure systems, Heating |

When selecting a refrigeration tee for your HVAC system, evaluating performance is crucial to ensure optimal functionality. The performance of a refrigeration tee can significantly influence the efficiency of the refrigerant flow through the system. Look for tees that offer minimal pressure drops and are constructed from materials that can withstand the operating conditions of your HVAC setup. Pay attention to the design and size of the tee, as an inappropriate choice can lead to turbulence in refrigerant flow, decreasing efficiency and potentially leading to system failures.

Compatibility with your HVAC system is another essential factor to consider when choosing a refrigeration tee. Ensure that the dimensions and connection types of the tee align with your existing pipeline. This includes checking the compatibility of the refrigerants used, as certain materials may degrade over time when exposed to specific chemicals. Additionally, consider the environmental conditions in which your system operates, such as temperature and humidity levels, as these can also affect the choice of materials for the refrigeration tee. By carefully evaluating these performance metrics and compatibility factors, you can make an informed decision that supports the longevity and efficiency of your HVAC system.

When installing refrigeration tees in HVAC systems, proper techniques and maintenance practices are crucial to ensure efficiency and longevity. According to the International Institute of Refrigeration, improperly installed fittings can lead to a 10-15% increase in energy consumption due to refrigerant leaks and pressure drops. Selecting high-quality materials is essential, as the strength and durability of the tee can directly impact the overall performance of the refrigeration system.

Regular maintenance of refrigeration tees is equally important. A study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that regular inspection of joints and fittings can prevent unexpected downtime by up to 30%. Technicians should routinely check for signs of wear and tear, ensure that all connections are properly sealed, and replace any components that show signs of corrosion or damage. Implementing a scheduled maintenance plan will not only improve efficiency but also extend the lifespan of the HVAC system, ultimately saving operational costs.