In the HVAC industry, efficient refrigerant recovery is crucial. The "Refrigerant Recovery Filter Drier" is a key component in this process. Expert Tom Harrison emphasizes, "The right filter drier makes all the difference in recovery efficiency." This highlights the importance of choice in equipment.

Many technicians struggle with the nuanced operation of refrigerant recovery systems. The filter drier plays a vital role in removing moisture and contaminants. However, improper usage can lead to inefficient recovery and system failures. It's not uncommon for technicians to overlook this component, leading to costly mistakes.

Investing time in understanding your Refrigrant Recovery Filter Drier can save headaches later. Knowledge about product specifications is essential. Distinguishing between different filter driers might seem trivial, but it matters. A small oversight could result in significant financial losses. Reflecting on practices leads to improvement, making efficiency achievable.

Understanding refrigerant recovery is crucial for HVAC professionals. This process involves removing refrigerant from the system to prevent environmental harm. Using the right equipment makes a significant difference. A recovery unit captures the refrigerant safely, ensuring it doesn't escape into the atmosphere.

Filter driers play a key role in this process. They remove moisture and contaminants from the refrigerant. This keeps the system running smoothly. Without a proper filter drier, issues can arise. Contaminants can damage components. Frequent failures may lead to unnecessary costs and repairs.

Maintaining filter drier efficiency is vital. Regular checks can prevent blockages. Ensure the filter is clean and functioning. Sometimes, technicians overlook this step. Neglect can lead to inadequate refrigerant recovery. Understanding these details helps technicians improve their practices. Delving into equipment functionality ensures better outcomes for everyone involved.

| Parameter | Recommended Value | Purpose | Tips |

|---|---|---|---|

| Initial Pressure | 0-5 psi | Ensure proper starting point for recovery | Check gauge regularly |

| Recovery Time | 10-30 minutes | Efficiency in operation | Monitor during the process |

| Filter Drier Replacement | Every 6 months | Maintain refrigerant purity | Use manufacturer’s specifications |

| Temperature Range | 36°F to 50°F | Optimize drier performance | Avoid exposing to extreme temps |

| Condensate Management | Drain every cycle | Prevent contamination | Check water levels regularly |

Efficient usage of filter driers in refrigerant recovery can yield significant benefits. A well-functioning filter drier helps to remove moisture and contaminants from the refrigerant. This is crucial in preventing system damage. Contaminated refrigerants can lead to costly repairs. Investing time in routine maintenance can extend the life of recovery equipment.

Usage efficiency also impacts the overall energy consumption of the system. A clean and effective filter drier improves refrigerant flow. This can reduce energy loss during recovery. However, many often overlook the importance of regular replacement. Ignoring this can lead to reduced efficiency. When the filter drier is clogged, the system works harder.

Not every technician prioritizes the condition of filter driers. This oversight can result in poor performance and increased downtime. Monitoring the pressure drop across the drier can provide valuable insights. A noticeable increase signals that it’s time for a change. Regular checks and proper training could enhance awareness. Ignorance in this area could cost both time and money.

Proper installation of a filter drier is crucial for efficient refrigerant recovery. Start by selecting the right location. Ensure it’s easily accessible for maintenance. Keep it away from heat sources.

Next, examine the existing piping. Look for any signs of wear or corrosion. Clean the area thoroughly before installation.

Connect the filter drier to the refrigerant line without twisting. Use the right torque specifications for all connections. This prevents leaks that can lead to inefficiencies. Pay attention to the flow direction marked on the drier. Misalignment can reduce performance. After installation, check for leaks. A simple bubble test can reveal issues that require immediate attention.

Operating the system after installation sometimes feels tricky. Monitor the pressure closely. If it fluctuates unexpectedly, there may be a problem. Regular checks help maintain optimal conditions. If issues arise, reflect on your steps. Did you skip any checks? Proper documentation of the installation process aids future troubleshooting. Notice any changes in system performance post-installation to ensure everything works smoothly.

When recovering refrigerants, mistakes can lead to inefficiencies and increased costs. A significant oversight is failing to ensure proper filtration. Reports indicate that improper filter drier usage can reduce efficiency by up to 30%. Many technicians neglect to replace filter driers as part of routine maintenance. Without this, contaminants can build up, affecting system performance.

Another common mistake is handling the recovery unit incorrectly. Technicians often connect hoses improperly, leading to leaks. A study found that up to 15% of recovered refrigerants can escape due to faulty connections. This not only wastes resources but can also harm the environment.

Moreover, some overlook the importance of adequate purging. Inadequate purging can leave residual refrigerant in the system. According to industry data, this can lead to overcharging in new units. Finally, technicians sometimes assume that all filter driers are the same. This overlooks critical specifications and leads to potential system failures. Educating technicians on these points can improve recovery efficiency significantly.

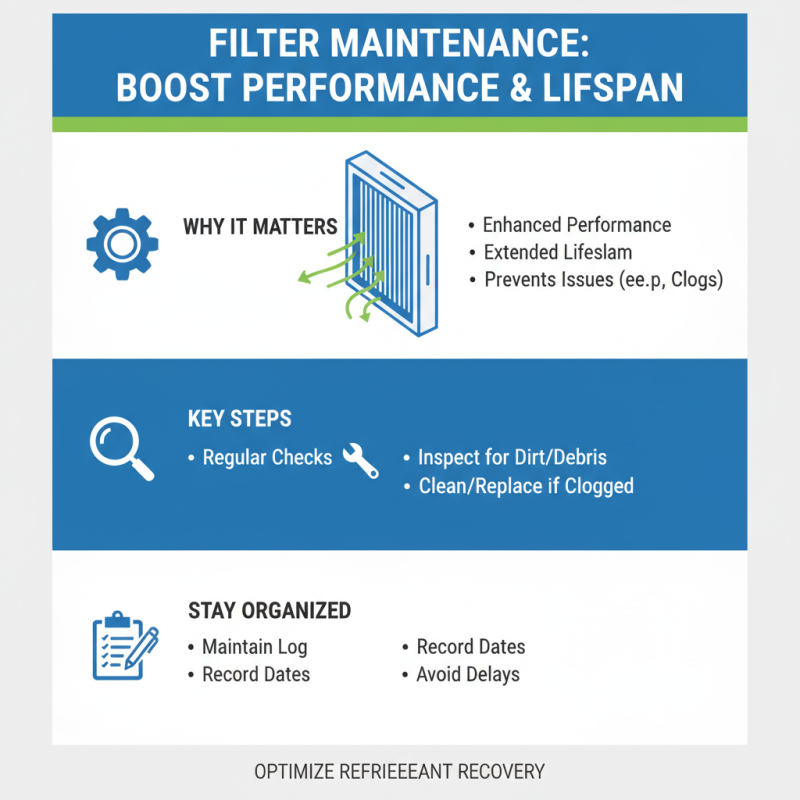

Proper maintenance of filter driers can significantly enhance their performance and lifespan. Regular checks are essential. Ensure that you inspect the filters for dirt and debris. A clogged filter can impede flow and increase pressure drop. Sometimes, people forget this step, leading to reduced efficiency. Keep a maintenance log to record when filters were last checked. This avoids unnecessary delays and mishaps during refrigerant recovery.

Another aspect to consider is the temperature environment. Filter driers work best within specific temperature ranges. If they operate outside this range, they may not perform well. Monitor ambient conditions regularly to ensure optimal operation. Pay attention to moisture levels within the system. Excessive moisture can cause the filter to become saturated. If this happens, performance decreases. Frequent monitoring is crucial, and don’t overlook documenting unusual spikes in humidity.

Lastly, consider proper installation as a part of your maintenance routine. An improperly installed filter drier can lead to significant issues. Check for leaks and ensure all connections are secure. Some technicians rush through installations and later face problems. Being diligent in this area can save time and resources in the long run. Remember, thoughtful maintenance leads to a more efficient and reliable system.