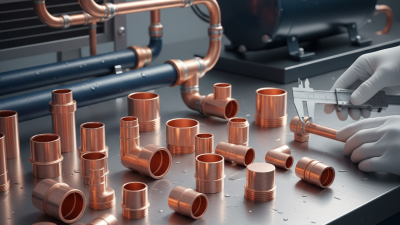

Choosing the right refrigeration copper fittings can significantly impact system efficiency. According to John Smith, an industry expert at CoolTech Solutions, "Quality fittings play a crucial role in preventing leaks." His insight highlights the importance of careful selection. Refrigeration copper fittings connect various components, ensuring effective fluid flow. However, with so many options available, mistakes can happen. Poor choices could lead to leaks or maintenance issues, costing both time and money. It's essential to understand the specifications that matter. For instance, the right diameter and wall thickness are critical for durability and performance. Many professionals overlook details when choosing refrigeration copper fittings. It’s easy to get swayed by price instead of quality. Remember, a lower cost may lead to higher long-term expenses. Thorough research and awareness of your system's needs can lead to better decisions. Quality fittings will not only save money but will also enhance overall system performance.

Copper plays a vital role in refrigeration systems. Its thermal conductivity is unmatched, ensuring efficient heat transfer. A study by the International Copper Association reveals that systems using copper pipe fittings achieve energy savings of up to 30%. This not only reduces operational costs but also enhances system reliability.

When choosing copper fittings, consider the compatibility with your refrigeration system. The fittings must match the type of refrigerant in use. Avoid using fittings designed for other materials. They can lead to leaks or inefficiencies. Remember, the right choice can lead to better energy consumption and longer system life.

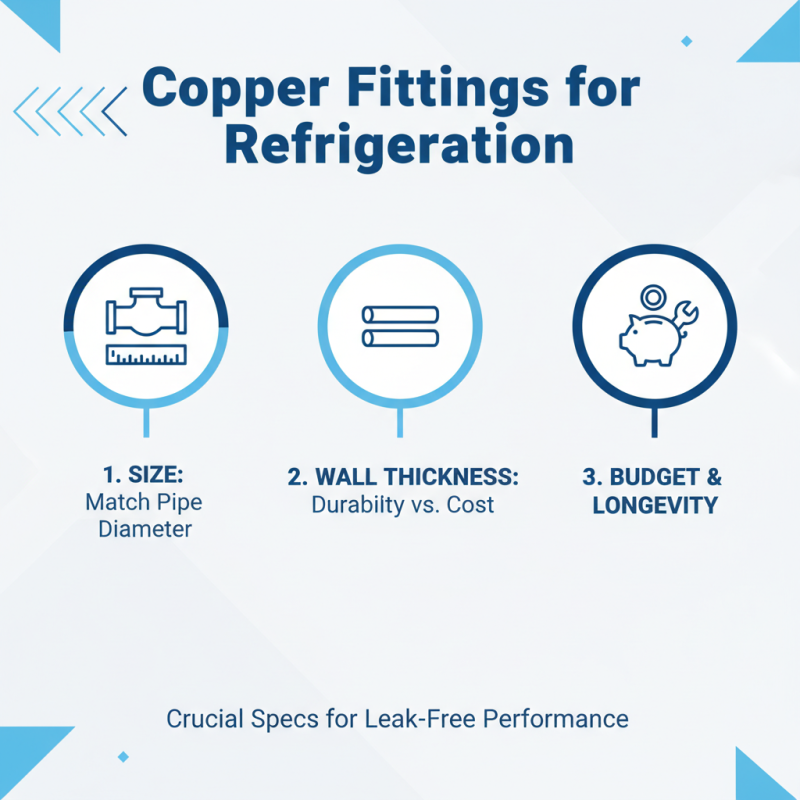

It's crucial to check the quality of the copper used. Not all copper is equal. Low-quality materials may corrode faster. A report from the American Society of Mechanical Engineers highlights that properly selected copper fittings can last over 30 years. Ensure you invest in durable fittings. Quality matters significantly in refrigeration systems, affecting both performance and safety.

When selecting copper fittings for refrigeration, several specifications play a crucial role. The size of the fitting is vital. Ensure it matches the pipe diameter precisely. A poor fit can lead to leaks. The wall thickness of the fitting also matters. Thicker walls offer better durability. However, more robust options may come with a higher price tag. Consider your budget versus the longevity required.

Another important aspect is the type of solder used with the fitting. Some fittings require a specific type of solder to ensure a secure joint. Choosing the incorrect solder can result in weak connections. Look for fittings rated for high pressure if your system demands it. This detail is often overlooked.

It’s essential to check the level of corrosion resistance. Not all copper fittings are created equal in this regard. Some may corrode quicker in specific environments. A fitting with a protective coating can prolong its lifespan. However, not every coating guarantees performance. Doing proper research is critical to avoid costly mistakes in your refrigeration project.

When selecting copper fittings for HVAC applications, evaluating their corrosion resistance is crucial. Corrosion can lead to leaks and reduced efficiency. Understanding the specific environmental conditions where the system operates is important. For instance, high humidity areas often accelerate corrosion. You may notice pitting or discoloration over time, which can indicate a problem.

Different types of copper alloys exhibit varying levels of corrosion resistance. You might find that some are better suited for certain applications than others. Extensive testing can provide insights into their durability. However, not all manufacturers offer thorough data on their products. It’s worth questioning their claims.

Inspecting the fittings regularly is essential. Look for signs of wear and tear. Establish a maintenance routine to catch issues early. While copper is generally resilient, it is not invulnerable. You might be surprised by how unnoticed corrosion can escalate. Don't overlook the importance of material selection based on the specific application. Proper choices can prevent future headaches.

| Tip Number | Tip Description | Corrosion Resistance Type | Common Applications | Expected Lifespan |

|---|---|---|---|---|

| 1 | Check for compatibility with refrigerants. | High | Chillers, Commercial AC | 15-20 years |

| 2 | Evaluate the thickness of the fittings. | Moderate | Cooling Lines, Refrigeration | 10-15 years |

| 3 | Select fittings with a protective coating. | High | Chilled Water Systems | 20+ years |

| 4 | Inspect for any signs of pitting or corrosion. | Low | Residential HVAC | 5-10 years |

| 5 | Consider the environment in which they will be installed. | Moderate | Outdoors, Coastal Areas | 10-15 years |

| 6 | Use fittings that meet industry standards. | High | Commercial Refrigeration | 15-20 years |

| 7 | Assess ease of installation and maintenance. | Moderate | Service Areas, HVAC Units | 10 years |

| 8 | Review technical specifications carefully. | High | Industrial Cooling Systems | 15+ years |

| 9 | Choose reputable suppliers for purchasing. | High | All HVAC applications | 20 years |

| 10 | Seek expert advice when uncertain. | N/A | Technical Consultation | N/A |

When choosing refrigeration copper fittings, size and compatibility are critical factors. The right size ensures a secure fit, preventing leaks. A fitting that is too large or too small can disrupt the cooling process. It may cause inefficiencies or even system failure. One common issue is the mismatch of pipe sizes. This can lead to increased pressure drop and reduced cooling efficiency.

Compatibility with the refrigeration system is equally important. Different systems require specific types of fittings. Mismatched materials can lead to corrosion or failure. Understanding the materials used in both the fittings and the system helps in making informed choices. It’s also essential to consider the refrigerant type. Some materials may not perform well with specific refrigerants.

Many users overlook these aspects, which can result in poor performance. The wrong size can create unexpected challenges. It might require additional adjustments or replacements down the line. Such oversights could lead to unnecessary costs. Paying attention to these details is vital for an efficient refrigeration system.

When it comes to installation and maintenance of copper refrigeration fittings, several best practices can ensure efficiency and longevity. Properly managing the temperature and pressure in refrigeration systems is crucial. A recent industry report highlights that over 30% of refrigeration failures stem from improper fittings, emphasizing the need for quality choices.

During installation, cleanliness is key. Any debris can cause leaks or inefficiencies. Always ensure the surfaces of the fittings are clean before soldering. Apply the correct heat to avoid damaging the copper integrity, as overheating can lead to brittleness.

Tip: Choose fittings that align with the system's requirements. Using the wrong sizes or types can result in operational failures.

For maintenance, regular inspections are essential. Corrosion is common in copper fittings, which can compromise system performance. Inspect joints and connections for any signs of wear. Clean the fittings periodically to prevent buildup.

Tip: Document all maintenance work, including inspection dates and findings. This practice can highlight potential issues before they escalate. Always strive for improvement, as even a small oversight can lead to larger system problems.