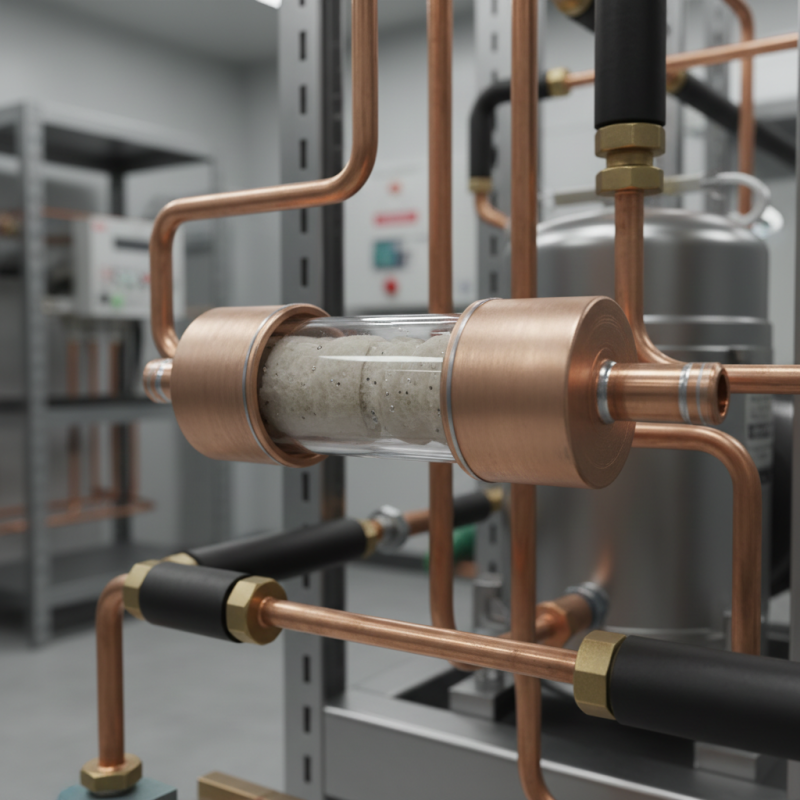

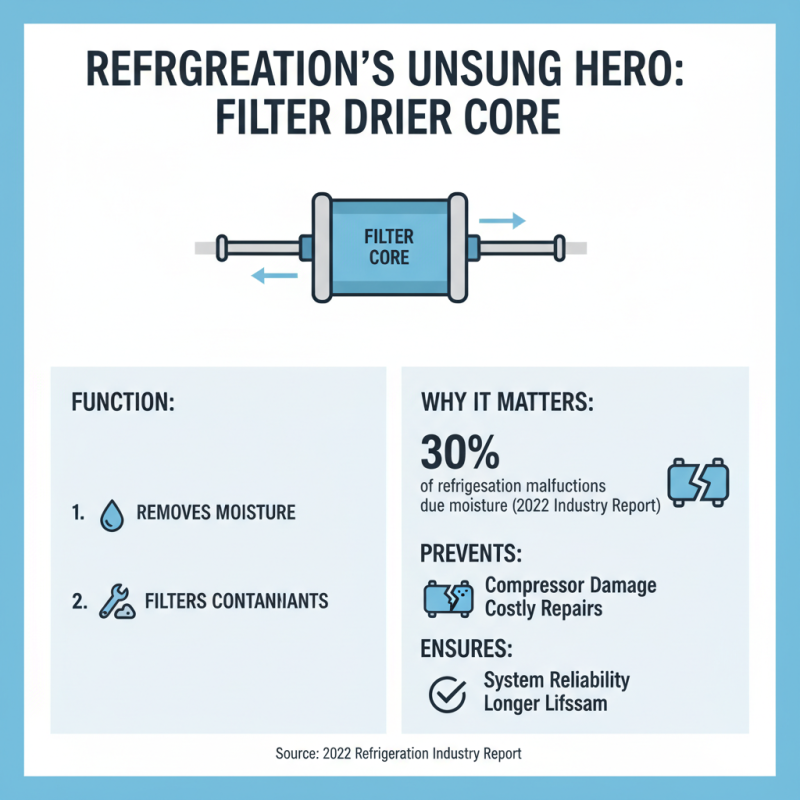

In refrigeration systems, maintaining optimal performance is crucial. One essential component in this process is the Filter Drier Core. This small yet powerful device plays a significant role in improving efficiency and longevity. It filters out moisture and contaminants from refrigerants, which can damage the system.

Without a reliable Filter Drier Core, systems may face various issues. For instance, increased wear on compressors can lead to costly repairs. Contaminants can cause blockages, disrupting the cooling process. This highlights the necessity of regular maintenance and timely replacements.

Ignoring the need for a Filter Drier Core may seem convenient, but the long-term consequences can be costly. Systems need protection from harmful substances. Every technician should recognize the importance of this component. It’s not just about cost; it’s about the integrity of the entire system.

Filter drier cores play a vital role in refrigeration systems. They remove moisture and contaminants from refrigerants. Without proper filtration, systems face increased risks of failure. A 2022 industry report noted that nearly 30% of refrigeration malfunctions are due to moisture buildup. This can lead to compressor damage and costly repairs.

Installing quality filter drier cores can significantly improve system efficiency. They help maintain optimal refrigerant flow and prevent corrosion. Statistics show that systems with effective filtration can operate up to 15% more efficiently. However, it's not just about installation. Regular maintenance is crucial. Neglecting to check these components can lead to performance declines that go unnoticed.

Some technicians overlook the importance of filter drier cores. They may think that installation alone is enough. This belief can be costly in the long run. A study indicated that over 40% of refrigeration systems fail because contaminants were not addressed properly. Addressing these issues early can create a more reliable cooling environment.

In refrigeration systems, contaminants can be detrimental. Dust, moisture, and dirt often infiltrate the system. If not filtered out, they can lead to inefficiencies. For instance, a small amount of moisture can freeze within the system, causing clogs. These clogs can lead to costly repairs and increased energy consumption. It's a simple issue, yet one often overlooked.

Understanding the importance of these contaminants is essential. They can corrupt the refrigerant and harm the compressor. When the compressor fails, the whole system struggles. A filter drier core helps catch these impurities, ensuring the refrigerant remains clean. This core acts as a barrier, preventing further damage. Even minor contaminants can wreak havoc. Regular checks on filter driers can save headaches down the line.

Some professionals neglect filter drier cores. They might assume their systems are clean. This false confidence can result in system failure. Taking a moment to check these components is vital. Understanding the contaminants and their effects is a step toward better maintenance. Focus on the details to ensure peak performance. Ignoring them can lead to bigger, costlier problems.

| Contaminant Type | Impact on System | Recommended Filtration Method | Frequency of Check (Months) |

|---|---|---|---|

| Moisture | Corrosion, decreased efficiency | Filter Drier Core | 6 |

| Acids | Component damage, system failure | Acid Neutralizing Filter | 3 |

| Dust & Debris | Clogging, inefficient operation | Particle Filter | 12 |

| Refrigerant Oil | Poor heat exchange, system efficiency | Oil Separator | 6 |

When maintaining a refrigeration system, understanding filter drier cores is essential. These components help purify refrigerants by removing moisture and contaminants. Several types of filter drier cores are specifically designed for different refrigeration applications.

One popular option is the bi-flow filter drier. It works efficiently in systems that allow refrigerant flow in both directions. This feature is vital for heat pumps and similar setups. Another choice is the liquid line filter drier, which is suited for traditional refrigeration systems. It targets moisture and debris, ensuring optimal operation.

Desiccant filter driers are also prevalent. These use drying agents to absorb moisture within the refrigerant. However, not all systems require the same filter drier. Sometimes, using the wrong type can lead to inefficiencies. Proper assessment is crucial. Careful selection can prevent costly repairs later. It's important to regularly check and replace filter drier cores as part of maintenance routines. This will ensure that the refrigeration system operates smoothly.

Installing a filter drier core is essential for any refrigeration system.

These components remove moisture and contaminants from refrigerants. A clean system operates more efficiently.

According to industry reports, moisture can cause system failures. It's estimated that

30% of refrigerant system issues stem from moisture accumulation.

Proper installation is crucial. Make sure to place the filter drier in the correct position within the system.

This ensures optimal performance. Always use proper fittings

and avoidance of leaks. Tightening connections results in fewer issues down the line.

Regular maintenance is just as important. Schedule checks every six months to monitor conditions.

Look for signs of wear and tear. Filter drier cores should be replaced

if they show signs of saturation or blockage. An old filter can lead to inefficient cooling.

Remember, neglecting these steps may cost you.

The filter drier core plays a crucial role in refrigeration systems. When it fails, the entire system can suffer. Common signs of failure include fluctuating system pressure, strange noises, and frequent refrigerant leaks. Ignoring these issues can lead to significant damage.

Tips: Check your system regularly. Look for any signs of wear or leaks. Keep an eye on the pressure readings. Consistent monitoring can prevent costly repairs.

Replacing a failed filter drier is essential. It's a straightforward process but requires attention. Start by safely retrieving the old core. If it's dirty or damaged, the replacement is necessary. Always ensure proper installation to avoid repeated issues.

Tips: Use clean tools to prevent contamination. Wear gloves and safety goggles for protection. Don't rush the installation; a careful approach often leads to better results.