In the realm of HVAC system maintenance, the role of a Filter Drier cannot be overstated. This essential component acts as a guardian of the system’s efficiency and longevity, ensuring that contaminants and moisture do not compromise the refrigerant cycle. By filtering out impurities and absorbing excess humidity, the Filter Drier contributes significantly to optimal performance and energy efficiency, making it a critical element in routine maintenance practices.

Moreover, neglecting the maintenance of a Filter Drier can lead to a series of complications, including system failures and costly repairs. A clean and functional Filter Drier not only prolongs the lifespan of the HVAC system but also enhances the comfort levels within a space by maintaining stable temperatures. As part of a comprehensive maintenance strategy, the importance of regularly inspecting and replacing the Filter Drier should never be underestimated. In this discussion, we will delve deeper into the crucial role of the Filter Drier in HVAC systems, the potential risks of overlooking its maintenance, and best practices for ensuring its effective operation.

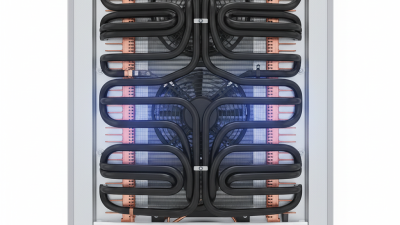

A filter drier plays a crucial role in the functioning and maintenance of HVAC systems. Its primary purpose is to remove moisture and impurities from the refrigerant, which is essential for preventing harm to various components of the system. Moisture, if not filtered out, can lead to corrosion, reduced efficiency, and even complete system failures. The filter drier absorbs water and traps debris, ensuring that only clean, dry refrigerant circulates through the system, thereby enhancing its longevity and reliability.

In addition to moisture removal, filter driers also contain desiccants that help to capture acidic contaminants and other harmful particles. These contaminants can significantly affect the overall performance and efficiency of the HVAC system. By maintaining a clean refrigerant environment, filter driers not only improve operational efficiency but also contribute to energy savings over time. Regularly checking and replacing filter driers is a vital step in HVAC maintenance, ensuring that systems operate smoothly and effectively throughout their lifespan.

A filter drier plays a crucial role in the maintenance of HVAC systems by ensuring the system operates efficiently and effectively. Its primary function is to remove moisture and contaminants from the refrigerant, which is essential for the longevity of the system. According to the Air Conditioning Contractors of America (ACCA), moisture in the refrigerant can lead to severe issues such as corrosion, reduced system performance, and compressor failure. In fact, a study by the U.S. Department of Energy indicates that over 30% of HVAC service calls are related to moisture-related problems, underlining the importance of a filter drier in preventing such failures.

To maximize the performance of your HVAC system, regular maintenance should include checking and replacing the filter drier as needed. A good practice is to change the filter drier whenever you service the system or if a refrigerant leak is detected. By eliminating moisture before it can cause damage, you can improve the reliability of your HVAC system and extend its lifespan significantly.

Tip: Always ensure that your HVAC technician checks the filter drier during routine inspections, as this can save you from costly repairs in the long run. Another tip is to maintain the proper refrigerant charge, as imbalances can also affect the filter drier's efficiency and overall system performance.

Regular maintenance is crucial for the efficiency and longevity of HVAC systems. By scheduling consistent check-ups, homeowners can identify and address minor issues before they escalate into major problems. This proactive approach not only enhances the performance of the HVAC unit but also improves indoor air quality and comfort levels. Routine inspections often include cleaning or replacing filters, checking refrigerant levels, and ensuring that all components are functioning correctly. These tasks can significantly reduce energy consumption and lower utility bills, ultimately contributing to a healthier environment.

One key component in maintaining an HVAC system is the filter drier, which plays an essential role in removing moisture and contaminants from the refrigerant. During regular maintenance, ensuring that the filter drier is clean and functioning properly helps to prevent potential damage to the compressor and other vital parts of the system. This not only prolongs the lifespan of the HVAC system but also maintains optimal performance. By prioritizing maintenance and regularly checking critical components like the filter drier, homeowners can enjoy a more reliable and efficient heating and cooling system year-round.

Ignoring filter drier issues in your HVAC system can lead to a host of serious problems. The filter drier plays a crucial role in removing moisture and impurities from the refrigerant, ensuring efficient operation of the system. When these components fail, trapped moisture can cause corrosion, refrigerant breakdown, and ultimately compressor failure. This not only increases repair costs but also shortens the lifespan of your HVAC system.

To avoid these dire consequences, regular maintenance and inspection of the filter drier are vital. Check the refrigerant levels consistently and monitor for signs of wear or leaks. If you notice any unusual noises or performance drops, it may be time to inspect the filter drier.

**Tips:** For optimal performance, replace the filter drier according to your HVAC system’s maintenance schedule. Additionally, consider upgrading to a high-efficiency filter drier that offers better moisture absorption and longer service life. Make sure to consult with an HVAC professional to address any specific issues or concerns.

| Issue | Consequences of Ignoring | Recommended Action |

|---|---|---|

| Restricted Flow | Decreased efficiency, higher energy costs, potential system damage | Regularly check and replace filter drier as needed |

| Moisture Contamination | Corrosion, compressor failure, system leaks | Use a moisture indicator and inspect regularly |

| Debris Accumulation | Poor performance, premature component wear | Install pre-filters and ensure regular cleaning |

| Age of Filter Drier | Reduced effectiveness leading to system malfunctions | Replace filter drier every 3-5 years |

When it comes to maintaining your HVAC system, the filter drier plays a crucial role in ensuring optimal performance and longevity. Selecting and replacing filter driers is not a task to be taken lightly; a well-chosen filter drier can prevent issues such as moisture contamination and system inefficiency.

When selecting a filter drier, the first tip is to consider the size and capacity of your HVAC system. It’s essential to match the filter drier to your system specifications to ensure it can adequately handle the refrigerant flow. Secondly, look for a filter drier that has a reliable moisture indicator. This feature allows you to easily monitor moisture levels and schedule replacements before issues arise. Finally, choose a drier that can filter both liquid and vapor, providing comprehensive protection against contaminants throughout the system.

Replacing a filter drier is equally important to maintain the health of your HVAC system. It is advisable to replace the filter drier whenever the system is opened for repairs or maintenance. Make sure to flush the system to remove any debris, and check for leaks before sealing everything back up. By following these tips, you can ensure the filter drier you choose and how you replace it contribute positively to your HVAC system's performance.