In the quest for enhanced operational efficiency and performance in industrial processes, the integration of advanced technologies is paramount. One such innovation, the "Filter Dryer For Compressor," plays a critical role in optimizing compressor performance by ensuring the removal of moisture and particulates that can impede functionality. According to a 2021 study by the International Journal of Compressor Technologies, systems equipped with filter dryers can reduce energy consumption by up to 15%, while extending the lifespan of compressors by nearly 30%.

This transformative approach not only enhances the reliability of compressed air systems but also contributes to significant cost savings, highlighting the indispensable value of filter dryers in modern industrial settings. As companies strive for higher efficiency and sustainability, the adoption of filter dryers represents a strategic move towards achieving these objectives.

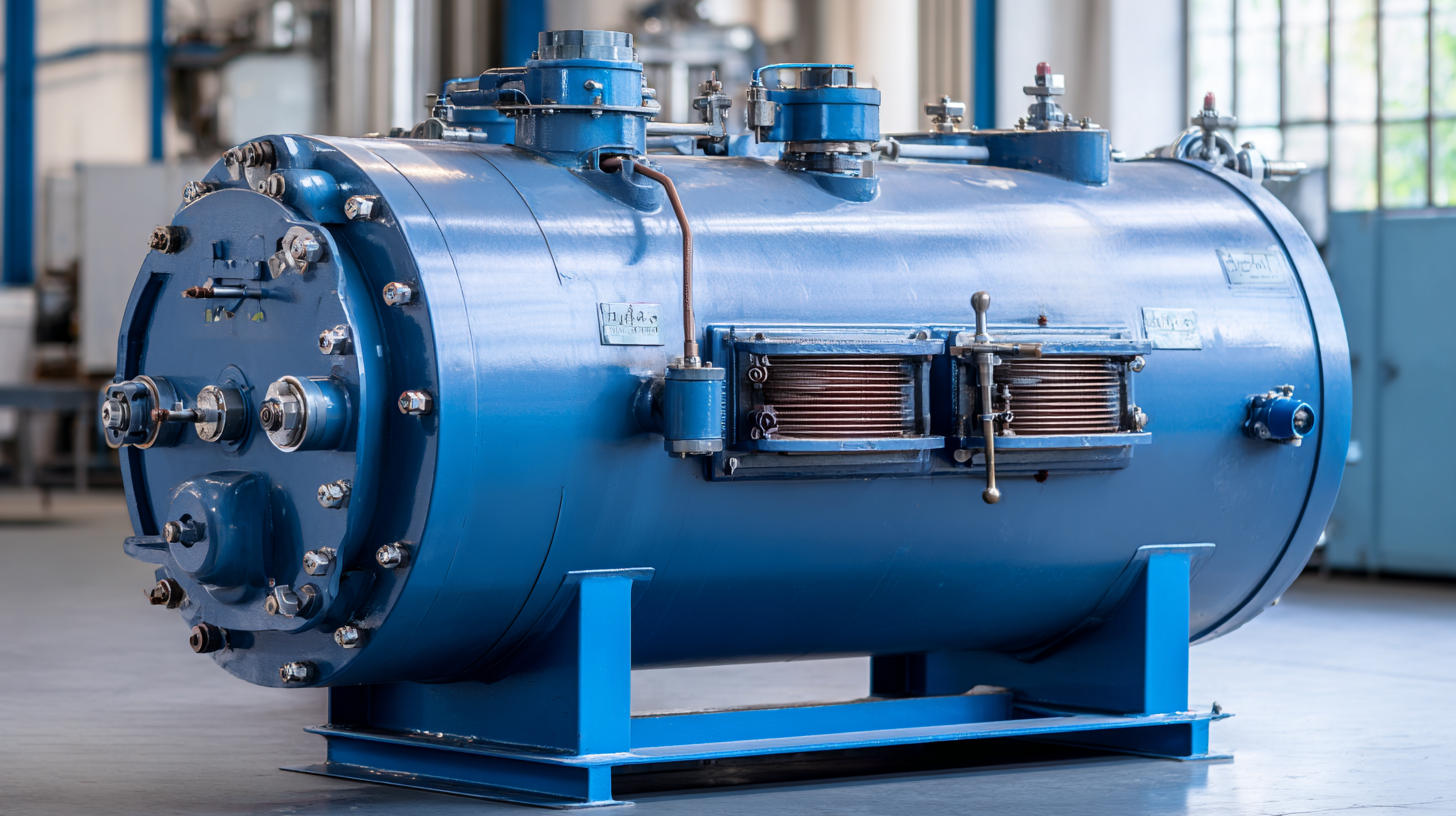

Filter dryers play a crucial role in enhancing the performance of compressor systems by ensuring that the compressed air remains clean and dry. As the demand for efficient air compression grows, integrating filter dryers can significantly minimize moisture and particulate contamination. This is particularly important as even small amounts of water vapor or dirt can lead to reduced efficiency and increased wear in compressor components, potentially causing costly downtimes. By maintaining optimal conditions, filter dryers help to prolong the lifespan of compressors and improve overall system reliability.

The compressed air filter and dryer industry is seeing substantial growth, with projections indicating an increase from USD 5.6 billion in 2023 to USD 7.4 billion by 2028, driven by a compound annual growth rate (CAGR) of 5.8%. This growth reflects the rising awareness among industrial users about the importance of maintaining air quality in compressor systems. Effective troubleshooting methods, such as utilizing a sight glass after the filter dryer, can also enhance performance by allowing operators to monitor potential clogging issues. As the market evolves, understanding the role of filter dryers will be essential for achieving greater efficiency and reliability in compressor operations.

This chart illustrates the efficiency percentage of compressor systems with and without filter dryers. The inclusion of filter dryers significantly enhances the performance of compressors.

Integrating filter dryers into compressor systems presents several key benefits that significantly enhance operational efficiency. One of the primary advantages is the removal of moisture and contaminants from the compressed air. By effectively filtering out these impurities, filter dryers prevent corrosion and wear within the compressor, leading to improved reliability and extended equipment lifespan. This ensures that the compressors operate at peak performance, minimizing downtime and maintenance costs.

In addition to preserving the mechanical integrity of compressors, filter dryers also enhance the overall energy efficiency of the system. When compressed air is free from moisture and contaminants, the compressor requires less energy to maintain optimum pressure levels. This reduction in energy consumption not only lowers operational costs but also contributes to a more sustainable industrial process. By investing in filter dryers, businesses can achieve significant savings and environmental benefits while ensuring that their compressor systems function efficiently and effectively.

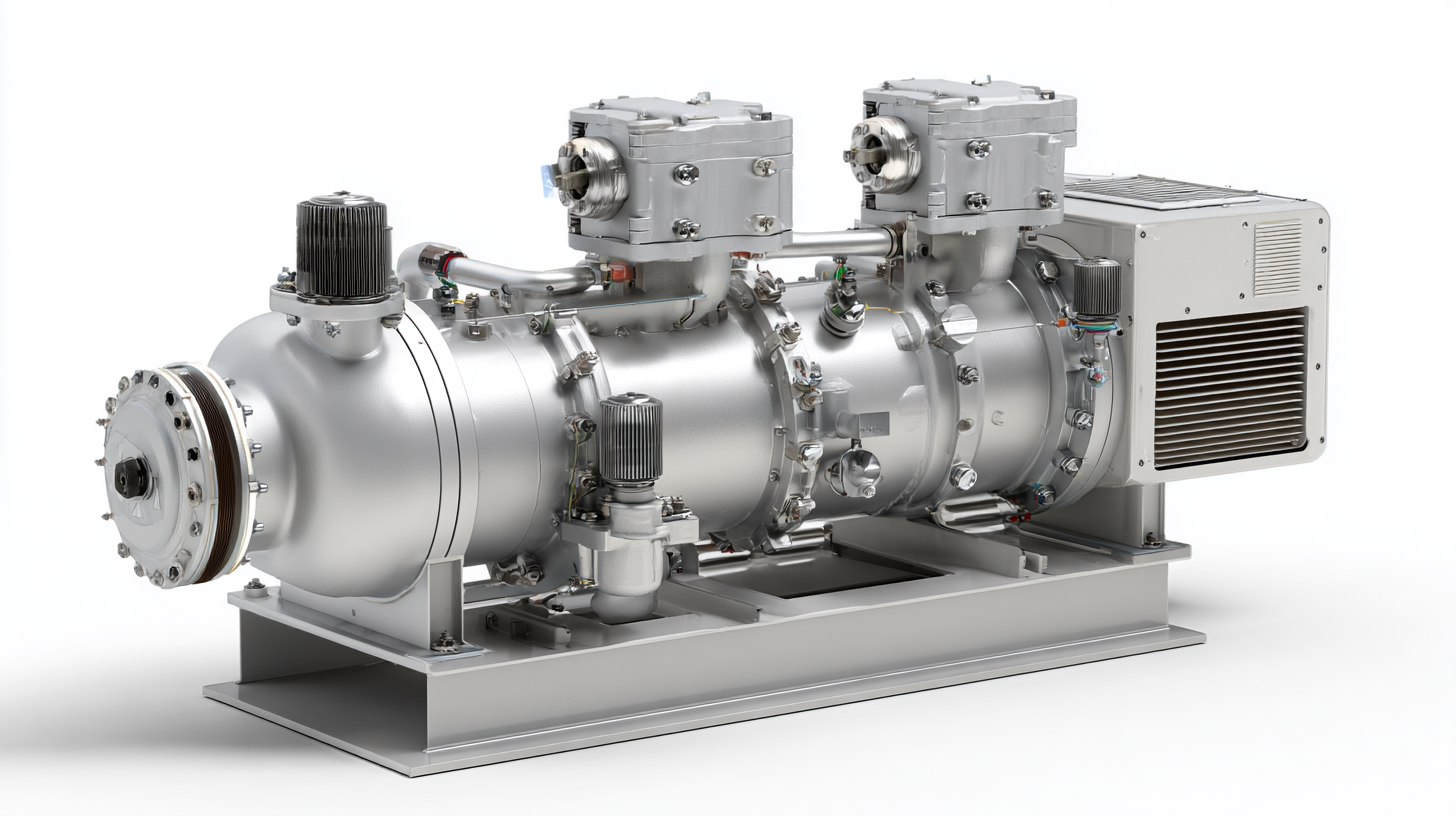

Installing filter dryers in compressor units is a vital step toward enhancing operational efficiency. The process begins with ensuring the compressor is fully powered down and isolated to ensure safety. Next, remove any existing components that might obstruct the installation path. Carefully inspect the filter dryer for any shipping damages before proceeding to mount it. Align the filter dryer with the inlet and outlet connections of the compressor, ensuring a snug fit to prevent leaks.

**Tips:** Always use the manufacturer’s specified tools for installation to prevent any potential damage. Double-check that all seals and gaskets are in good condition before closing up the unit.

Once the filter dryer is mounted, connect the appropriate piping and tighten all fittings securely. It's essential to follow the prescribed torque specifications to avoid future issues. After the connections are made, re-establish power to the compressor and conduct a thorough leak test to verify installation integrity.

**Tips:** Maintain a clean work environment during installation, as dirt and debris can compromise the system’s efficiency. Keep a maintenance schedule to periodically check the filter dryer’s condition for optimal performance.

Filter dryers play a crucial role in enhancing the performance of compressors by addressing several common issues faced during compression processes. One of the key challenges in these systems is the presence of moisture and contaminants in the compressed air. Moisture can lead to corrosion, reduced efficiency, and even breakdowns. By integrating filter dryers into the compression system, operators can significantly reduce the moisture content, thereby extending the lifespan of the equipment and improving overall performance.

Another significant issue mitigated by filter dryers is the accumulation of solid particles and oils in the compressed air. These contaminants can obstruct valves, cause wear and tear on internal components, and impact the quality of end products, especially in sensitive applications. Filter dryers effectively capture these unwanted substances, ensuring that only clean, dry air enters the compressor. This not only enhances the reliability of the system but also minimizes maintenance costs, leading to more efficient operations and better energy savings in the long run.

Maintaining filter dryers is crucial for maximizing compressor performance. Regular inspection and cleaning of the filter elements can prevent clogs that reduce airflow and increase energy consumption. It's essential to follow the manufacturer's guidelines on replacement schedules, as worn filters can lead to diminished separation efficiency and increased operational costs. Additionally, monitoring the pressure drops across the filter can help identify when maintenance is needed, ensuring optimal performance levels.

Proper installation and alignment of filter dryers also play a significant role in their effectiveness. Ensuring that the drainage and airflow paths are unobstructed allows for smooth operations and prevents moisture buildup, which can adversely affect compressor function. Implementing a routine maintenance schedule, including checks for leaks and the integrity of seals, will contribute to enhanced reliability and efficiency. Adhering to these best practices not only prolongs the lifespan of the filter dryers but also elevates overall compressor performance, ensuring a stable and efficient operation.

| Dimension | Value | Best Practices |

|---|---|---|

| Airflow Efficiency | 90% | Regular filter replacements |

| Operating Temperature | 75°F | Monitor and adjust cooling systems |

| Pressure Drop | 3 psi | Optimize filter selection |

| Maintenance Frequency | Monthly | Schedule routine inspections |

| Operational Costs | $500/month | Implement energy-efficient practices |

| Downtime Risk | 5% | Conduct regular performance audits |