In the HVAC industry, optimizing the efficiency of Refrigerant Recovery Filter Driers is crucial for enhancing system performance and reducing environmental impact. According to a recent report by the U.S. Environmental Protection Agency, improper refrigerant recovery can lead to significant ozone depletion, with millions of pounds of refrigerants escaping into the atmosphere annually. The implementation of innovative techniques in filter drier design and operation can improve refrigerant recovery rates by up to 30%, as highlighted in the 2022 HVAC Efficiency Benchmark Report. These advancements not only help in achieving compliance with regulations but also contribute to energy savings, benefitting both the environment and operational costs. By leveraging cutting-edge technologies and best practices, HVAC professionals can ensure that their systems are optimized for effective refrigerant recovery, ultimately leading to enhanced sustainability and efficiency within the industry.

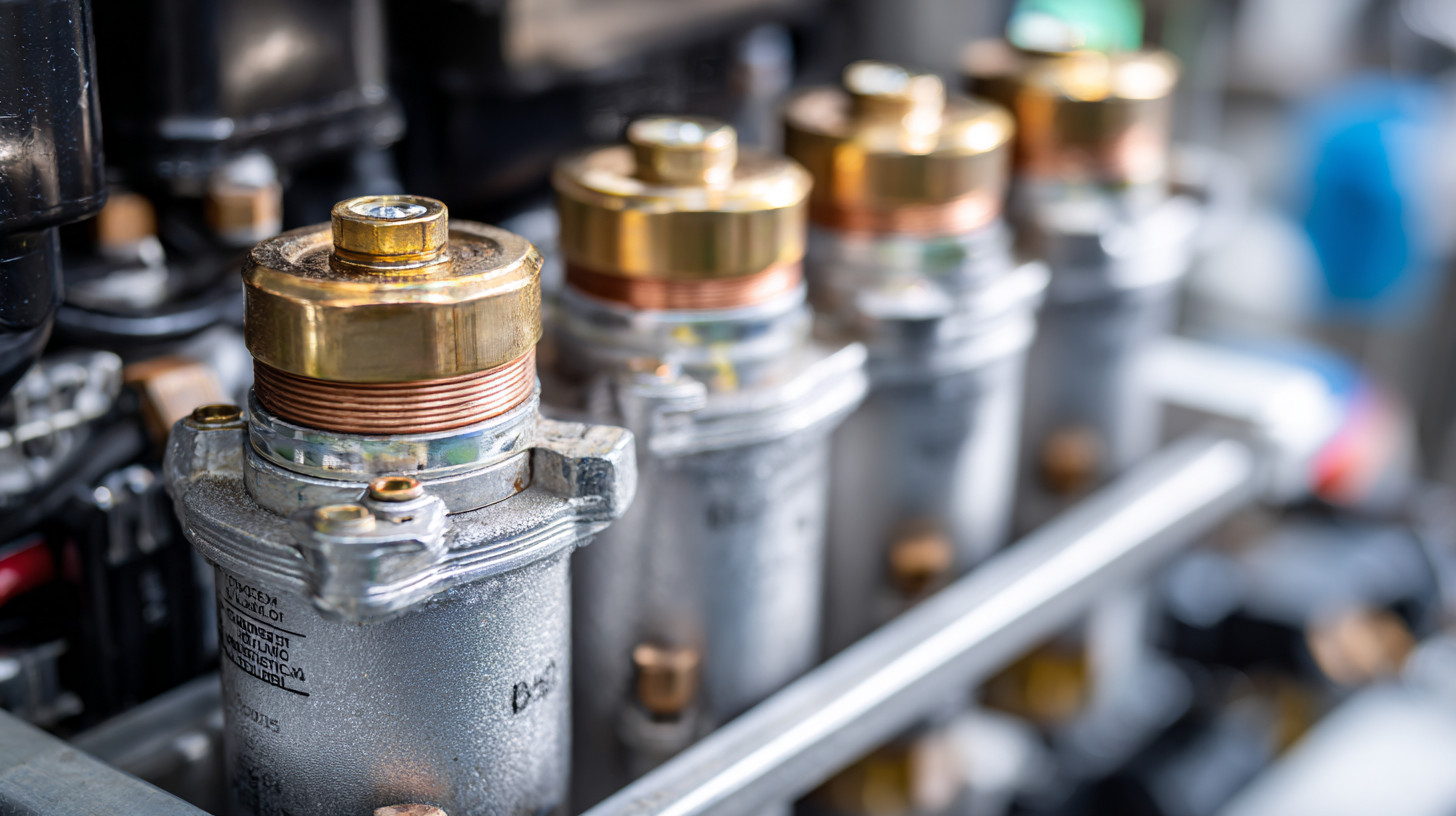

Innovative filter drier designs play a crucial role in

enhancing refrigerant recovery efficiency within HVAC systems. Traditional filter driers often face challenges in effectively capturing contaminants and moisture, which can hinder the overall performance of the refrigeration cycle. By incorporating advanced materials and configurations, modern filter driers are engineered to provide superior filtration and moisture removal. For instance, the use of molecular sieves and enhanced desiccants allows for better adsorption of moisture, leading to cleaner refrigerant pathways and improved operational efficiency.

Innovative filter drier designs play a crucial role in

enhancing refrigerant recovery efficiency within HVAC systems. Traditional filter driers often face challenges in effectively capturing contaminants and moisture, which can hinder the overall performance of the refrigeration cycle. By incorporating advanced materials and configurations, modern filter driers are engineered to provide superior filtration and moisture removal. For instance, the use of molecular sieves and enhanced desiccants allows for better adsorption of moisture, leading to cleaner refrigerant pathways and improved operational efficiency.

Incorporating innovative designs such as

dual-stage filtering systems can further optimize the recovery process. These systems utilize a combination of coarse and fine filters, ensuring that both large particulates and microscopic contaminants are effectively removed from the refrigerant. Additionally, the integration of smart technology into filter drier designs allows for real-time monitoring of refrigerant quality, which aids technicians in identifying issues promptly and maintaining optimal system performance. These advancements not only enhance refrigerant recovery efficiency but also contribute to the longevity and reliability of HVAC systems, ultimately reducing maintenance costs and environmental impact.

The efficiency of refrigerant recovery filter driers in HVAC systems is heavily influenced by the choice of sorbent materials. Recent studies indicate that the specific surface area and pore size distribution of sorbents significantly impact their moisture and contaminant removal capabilities. For instance, activated alumina has been recognized for its high affinity for water with a moisture removal capacity that can exceed 10% by weight. This characteristic makes it a popular choice in applications where low humidity levels are crucial for optimal system performance.

In contrast, zeolite sorbents offer superior adsorption kinetics and thermal stability, which can enhance the overall efficiency of filter driers. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), systems using advanced zeolite materials demonstrated a reduction in pressure drop by up to 20%, leading to improved energy efficiency. Moreover, integrating composite materials that combine the properties of traditional sorbents with novel engineered solutions has shown promise in extending the service life of filter driers and minimizing maintenance costs in HVAC systems. Such innovations are at the forefront of enhancing performance and sustainability in refrigerant recovery processes.

| Sorbent Material | Filter Drier Efficiency (%) | Pressure Drop (Pa) | Recovery Rate (kg/hr) | Operational Temperature Range (°C) |

|---|---|---|---|---|

| Activated Carbon | 85 | 150 | 10 | -10 to 50 |

| Molecular Sieve | 90 | 120 | 12 | -20 to 60 |

| Silica Gel | 82 | 160 | 9 | -10 to 40 |

| Alumina | 88 | 140 | 11 | -15 to 55 |

| Synthetic Polymer | 86 | 130 | 10.5 | -5 to 45 |

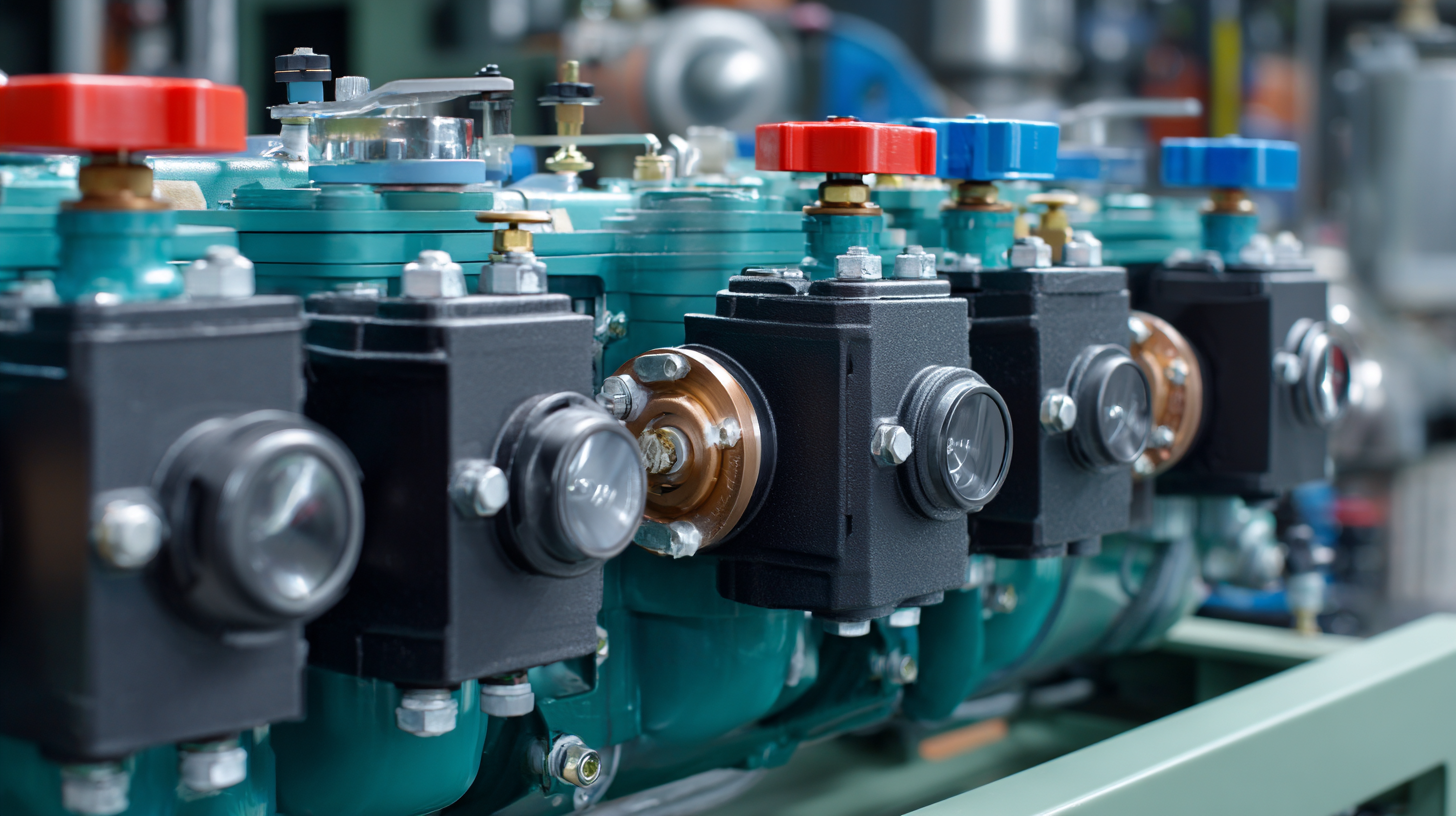

Harnessing advanced sensor technologies for real-time monitoring in HVAC systems is a game-changer for optimizing refrigerant recovery filter drier efficiency. By integrating Internet of Things (IoT) devices and advanced analytics, facilities can achieve significant improvements in energy efficiency and refrigerant management. According to industry reports, the incorporation of real-time data can enhance operational efficiency by up to 30%, leading to cost savings and reduced environmental impact.

To further illustrate, the use of AI algorithms in real-time monitoring can identify anomalies in refrigerant flow or filter drier performance, allowing facilities to address issues before they escalate. Such proactive measures not only ensure compliance with environmental regulations but also contribute to a more sustainable operation. Tips for implementing this technology include starting with a comprehensive assessment of existing HVAC systems and investing in IoT-ready sensors that provide actionable data.

Moreover, leveraging cloud-based technology for air quality monitoring has indicated improved decision-making for HVAC operators. By continuously monitoring system performance and refrigerant levels, operators can optimize maintenance schedules based on actual usage patterns and performance data. This approach allows for a significant reduction in downtime and operational costs. Regularly updating monitoring technologies is crucial for maintaining system efficiency and adapting to newly emerging standards in the HVAC industry.

In recent years, energy-efficient practices in HVAC refrigerant management have taken center stage as the industry strives to minimize environmental impacts while optimizing system performance. According to the International Institute of Refrigeration, refrigerant management can account for up to 70% of energy savings in HVAC systems when implemented correctly. Employing advanced techniques such as the installation of high-efficiency filter driers can drastically enhance refrigerant recovery efficiencies, thereby reducing waste and improving overall system reliability.

Moreover, a report by the U.S. Department of Energy emphasizes that proper refrigerant management not only reduces greenhouse gas emissions but also can save businesses up to 30% on energy costs over the lifespan of their HVAC systems. Techniques such as regular maintenance checks, incorporating advanced monitoring technologies, and adopting LEED-certified equipment are pivotal in achieving these energy savings. As the market continues to innovate, embracing these energy-efficient practices will be crucial for HVAC professionals aiming to lead in sustainable refrigerant management.

The importance of regulatory standards in shaping refrigerant recovery techniques cannot be overstated. The Environmental Protection Agency (EPA) in the United States has established stringent regulations under the Clean Air Act, which require the proper recovery and recycling of refrigerants. According to the EPA, approximately 15% of the refrigerant used in HVAC systems is lost every year due to improper recovery practices. This loss not only poses environmental risks but also financially burdens HVAC companies, highlighting the need for adherence to regulations.

Additionally, the introduction of standards such as the European Union’s F-Gas Regulation has driven innovation in refrigerant recovery filter drier technologies. These regulations mandate reducing Fluorinated Greenhouse Gas emissions by limiting the use of certain refrigerants and promoting efficient recovery systems. A report from the International Energy Agency (IEA) indicates that adherence to such regulations can lead to a 30% reduction in refrigerant emissions, thereby enhancing the overall efficiency of HVAC systems while maintaining compliance. As a result, HVAC contractors are increasingly investing in advanced recovery systems that align with regulatory requirements, reflecting a pivotal shift in the industry towards sustainability and efficiency.

This chart illustrates the efficiency of different refrigerant recovery filter drier optimization techniques based on their impact on recovery time and compliance with regulatory standards.