In the world of HVAC systems, understanding the role of a Liquid Line Filter Drier is crucial. According to industry expert John Smith, "A Liquid Line Filter Drier is essential for system performance and longevity." This device serves as a key component in keeping refrigerants clean and free from moisture.

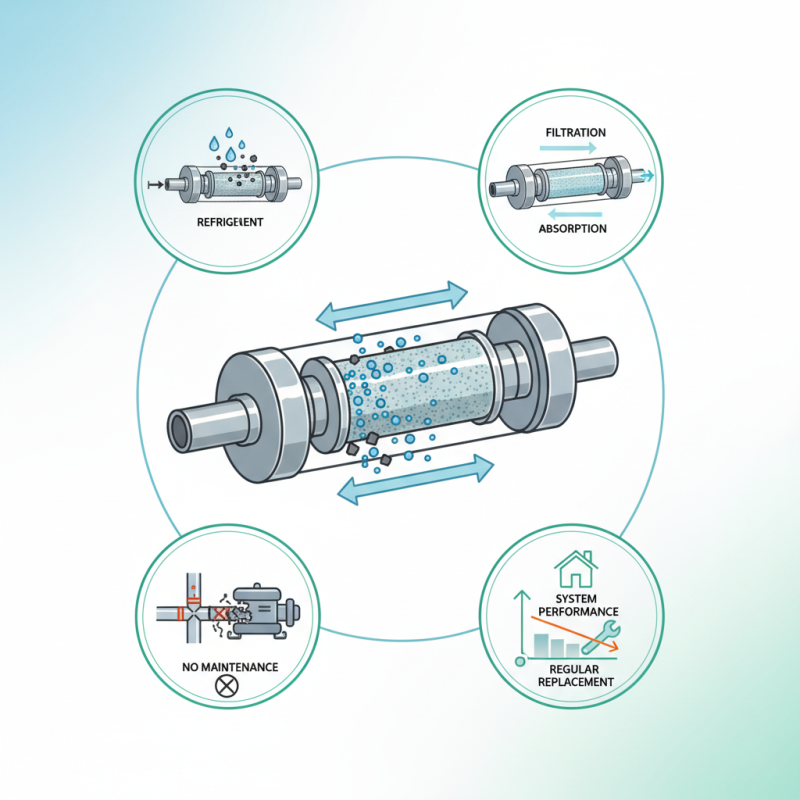

The Liquid Line Filter Drier operates by filtering out contaminants and absorbing moisture from refrigerants. This process helps prevent corrosion and damage to other components in the system. Yet, many technicians overlook the importance of regular maintenance. Failure to replace a clogged filter drier can lead to inefficiency and higher energy costs.

Moreover, the design of a Liquid Line Filter Drier can be improved, but this requires careful consideration. It's not always easy to determine the right size or type for specific applications. Awareness of these nuances can lead to better system performance, but it also demands continuous learning and adaptation from professionals in the field.

A liquid line filter drier plays a crucial role in HVAC systems. It ensures that refrigerants remain uncontaminated. This device removes moisture and particulate matter. According to industry reports, nearly 90% of system failures relate to contamination. Such statistics highlight the importance of maintaining clean refrigerants.

The filter drier is placed in the liquid line. It includes a desiccant material that absorbs moisture. Typically, the size of the drier correlates with the system's capacity. A suitable filter drier can help improve efficiency and extend the lifespan of components. Industry experts suggest regular checks to guarantee optimal performance.

Improper installation can lead to issues. For example, an incorrectly sized drier may not capture all contaminants. Such oversights can undermine the system’s efficiency. Awareness of these pitfalls is vital for technicians. A detailed understanding of a liquid line filter drier can help prevent common mistakes. Keeping these details in mind fosters better HVAC system performance.

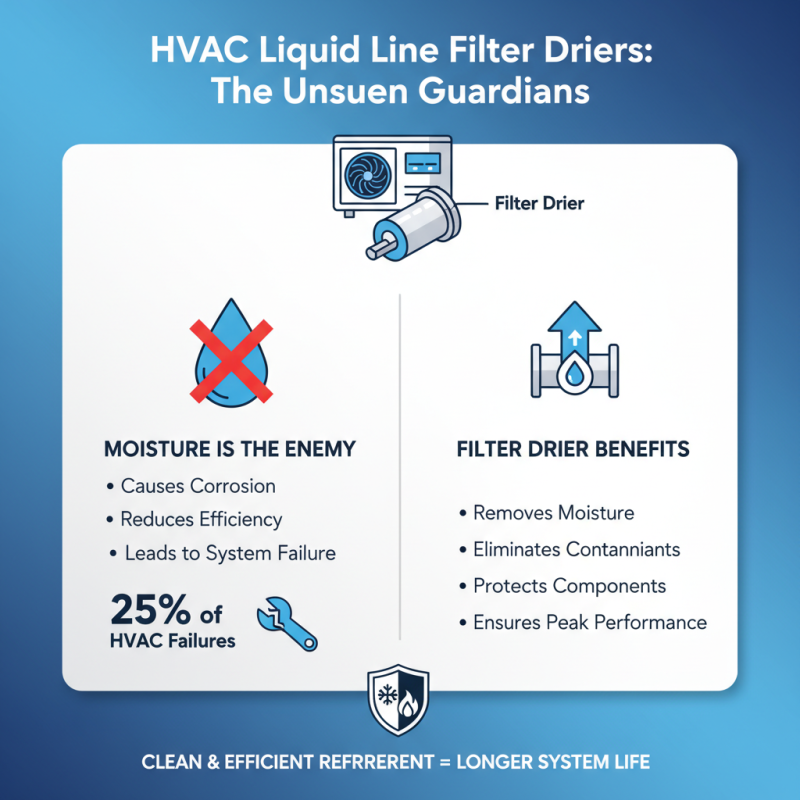

Liquid line filter driers are crucial components in HVAC systems. They serve a vital purpose by removing moisture and contaminants from the refrigerant. Moisture can lead to serious issues, such as corrosion and reduced efficiency. Studies show that up to 25% of HVAC failures are linked to moisture-related problems. This statistic emphasizes the importance of maintaining a clean refrigerant environment.

In practical terms, a filter drier collects dirt, debris, and moisture. It allows the refrigerant to flow seamlessly, ensuring optimal system performance. Clogged or malfunctioning drier units can impede refrigerant flow, resulting in increased energy consumption. This situation can lead to higher utility bills and more frequent repairs. Interestingly, many technicians may overlook routine maintenance, not realizing that nearly 15% of HVAC systems operate with some form of contamination.

Choosing and installing an appropriate liquid line filter drier can extend the life of the HVAC system. There is an ongoing debate in the industry about the best types of driers for specific applications. Variances in refrigerants and system design add layers of complexity. Ultimately, the effectiveness of a filter drier depends not only on its design but also on regular checks and maintenance practices.

A Liquid Line Filter Drier is essential in refrigeration systems. It removes moisture and impurities from refrigerants. This function prevents clogging and system damage. The filter drier typically contains desiccant materials. These materials absorb moisture effectively. According to industry surveys, systems can lose up to 15% efficiency due to contaminants. It's crucial to address this issue promptly.

In refrigeration cycles, the liquid line filter drier operates in a key location. It is situated between the condenser and the expansion valve. The filter drier allows liquid refrigerant to flow while trapping contaminants. This positioning helps maintain optimal system performance. If the filter drier becomes saturated, it can lead to increased pressure drop. This situation can stress the compressor, potentially causing failure.

Regular maintenance checks are often overlooked. Some technicians might ignore the filter drier until a service breakdown occurs. This reactive approach can lead to costly repairs. Industry reports suggest that proactive maintenance can extend system life by up to 20%. Awareness of the filter drier's role can enhance efficiency and system longevity. It’s an area worthy of reflection in any refrigeration strategy.

Liquid line filter driers are essential components in refrigeration and air conditioning systems. They help remove moisture and contaminants from the refrigerant. There are several types of liquid line filter driers available, each suited for specific applications.

The three common types are bi-flow, hermetic, and field-serviceable. Bi-flow filter driers are used in heat pumps. They work in both cooling and heating modes. Hermetic filter driers are sealed units, ideal for compact systems. Field-serviceable driers allow technicians to replace the filter when necessary. This flexibility can save costs in maintenance.

Tips: Always assess the environment of your system. Extreme conditions can impact filter life.

Choosing the right type is crucial for system efficiency. Misjudging your needs can lead to issues. Always consult with an expert if unsure. Regular maintenance is vital. Dirty or damaged filter driers can lead to reduced performance, causing system stress.

Tips: Monitor your system's pressure levels. This can indicate filter health.

Liquid line filter driers play a crucial role in maintaining the efficiency of refrigeration systems.

They are essential for removing moisture and contaminants from the refrigerant. However, they require regular maintenance to function optimally.

Neglecting this aspect can lead to serious problems. System failures may occur, and costly repairs could follow.

Replacing a liquid line filter drier is an important task. Signs of a malfunctioning drier include frequent refrigerant leaks and system freeze-ups.

It’s vital to address these issues promptly. Changing the filter drier typically takes a few hours. During this process, ensure the system is properly evacuated.

This step prevents any leftover contaminants from causing further issues.

Periodic checks can help identify issues early. Keep an eye on pressure readings and listen for unusual noises.

These could indicate a problem with the filter drier. Regular maintenance may seem tedious but can save time and money in the long run.

A little effort in monitoring the system can lead to increased reliability and efficiency.