In today's energy-conscious world, the efficiency of appliances is more critical than ever, particularly for compact devices like the mini fridge. Understanding the mechanism behind mini fridge compressor efficiency is essential for manufacturers, consumers, and environmental advocates alike. According to a report by the U.S. Department of Energy, refrigerators account for approximately 7% of residential energy consumption, with mini fridges often being less efficient due to their design constraints and smaller size.

Advances in compressor technology, particularly those utilizing inverter-driven systems, have shown a potential energy savings of up to 30% compared to traditional models. By exploring the intricate workings of mini fridge compressors, we can uncover strategies for enhancing their performance, reducing energy usage, and ultimately contributing to a more sustainable future.

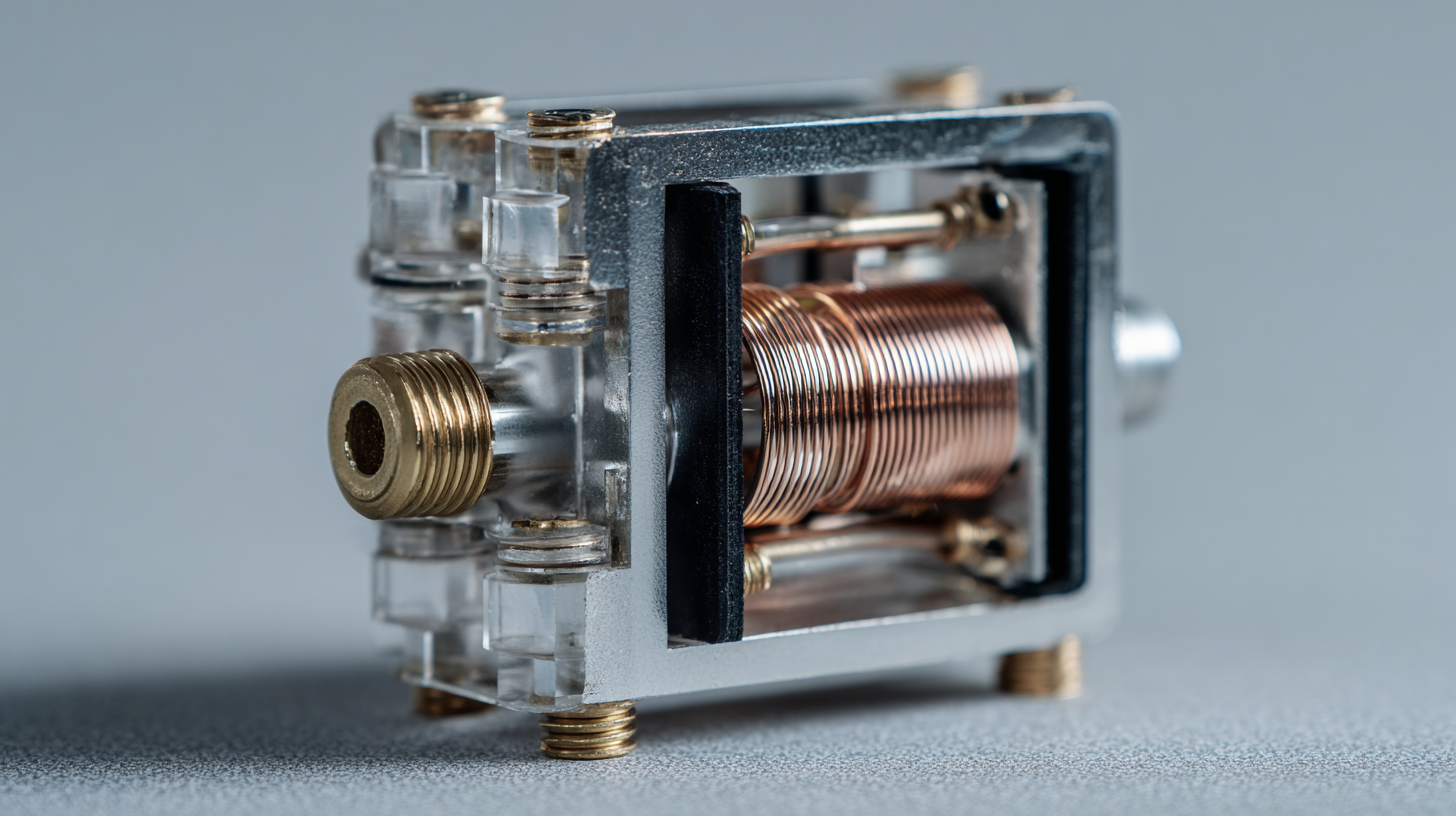

Mini fridge compressors are crucial to the efficient functioning of refrigeration units, playing a key role in energy transfer. The fundamental mechanism involves the vapor-compression cycle, where refrigerant absorbs heat and evaporates within the evaporator coils, subsequently being compressed into a high-pressure gas by the compressor. Industry reports indicate that optimizing the compressor's efficiency can lead to significant reductions in energy consumption—up to 30% in some cases.

The energy transfer process within these compressors is heavily influenced by several factors, including refrigerant type, compressor design, and thermal insulation within the fridge. For instance, using high-efficiency compressors, such as those utilizing variable speed technology, can improve energy transfer rates and reduce operational costs. According to a study by the U.S. Department of Energy, refrigerators equipped with Energy Star-rated compressors can save consumers around $200 over the lifespan of the unit, highlighting the importance of these mechanisms in both economic and environmental contexts.

The efficiency of mini fridge compressors is primarily determined by various factors that encompass both technical specifications and operational practices. One critical aspect influencing compressor efficiency ratings is the design of the compressor itself. Compressors equipped with advanced technologies, such as variable speed drives, can adjust their output to match cooling demands, leading to significant energy savings compared to fixed-speed models.

Additionally, the materials used in the construction of the compressor play a vital role in its overall efficiency. High-quality components can enhance thermal conductivity and reduce energy loss, contributing to a more efficient cooling process. Moreover, external conditions like ambient temperature and airflow also affect compressor performance. Industry standards often emphasize the importance of testing compressors under specified operating conditions to establish realistic efficiency ratings, ensuring consumers make informed decisions when selecting mini fridges for energy use and performance.

This bar chart illustrates the efficiency ratings of mini fridge compressors, highlighting key factors such as energy consumption, cooling capacity, noise level, and durability. These dimensions significantly influence overall compressor efficiency in the industry.

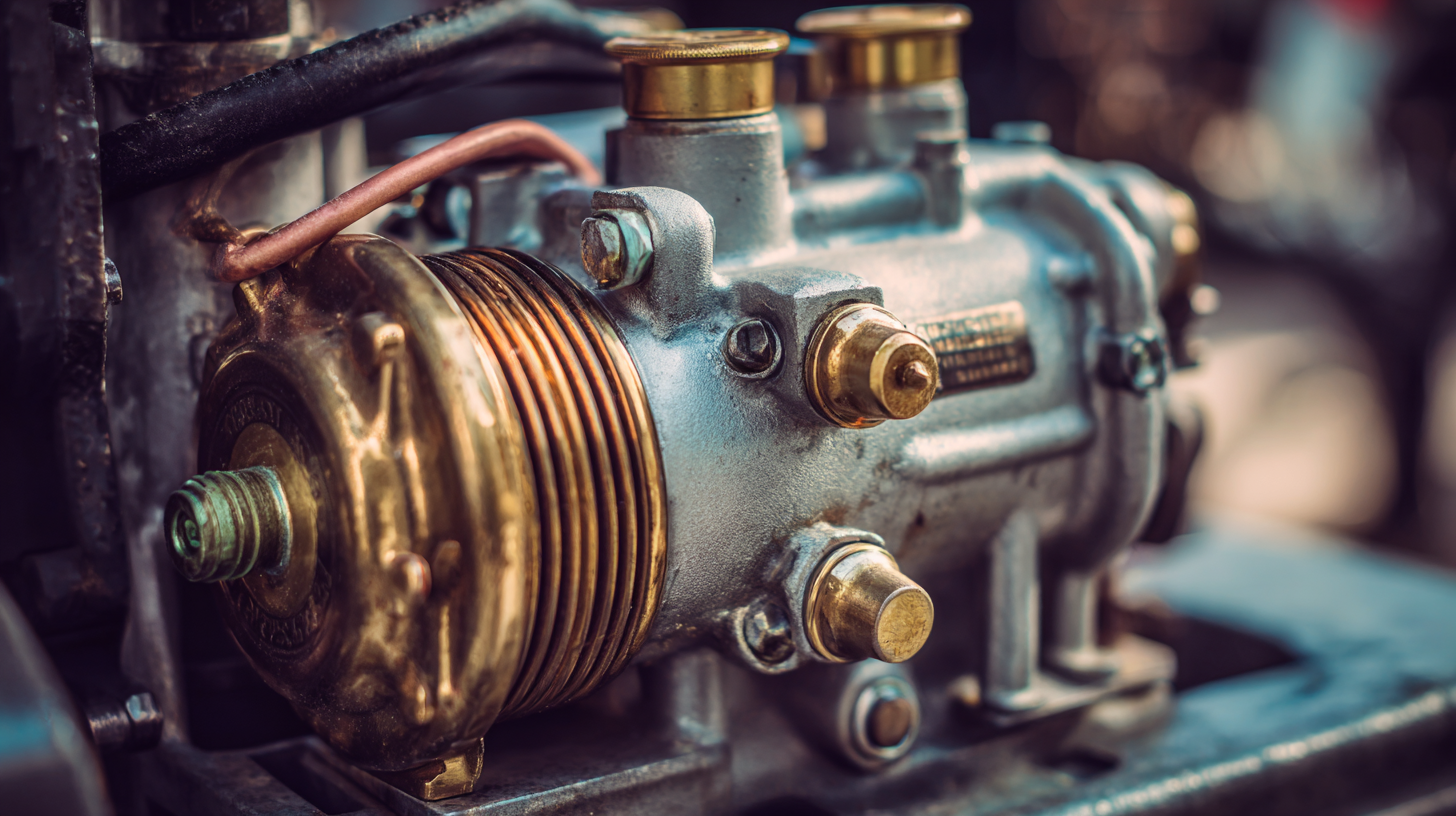

The performance of mini fridge compressors is significantly influenced by the type of refrigerant used. Traditional refrigerants like R-134a and R-12 have been staples in refrigeration technology, but their environmental impact has spurred the development of alternatives. New refrigerants, such as R-600a (isobutane) and R-290 (propane), are gaining popularity due to their lower global warming potential and higher energy efficiency. These newer options not only reduce the carbon footprint of mini fridges but can also enhance cooling performance, making them more effective for compact refrigeration applications.

Switching to different refrigerants affects the thermodynamic properties of the compressor, including its pressure and temperature profiles. For instance, hydrocarbons such as R-600a tend to operate at lower pressures and can lead to more efficient heat exchange processes. This results in less energy consumption and a quieter operation. However, the flammability of some alternative refrigerants poses safety considerations that manufacturers must address. Therefore, the choice of refrigerant is crucial, as it directly impacts both the efficiency and safety of mini fridge compressors, ultimately shaping their overall effectiveness in meeting consumer needs.

| Refrigerant Type | Energy Efficiency Ratio (EER) | Cooling Capacity (BTU/hr) | Power Consumption (W) | Environmental Impact (GWP) |

|---|---|---|---|---|

| R-134a | 3.0 | 200 | 66 | 1430 |

| R-600a | 4.0 | 180 | 45 | 3 |

| R-290 | 3.5 | 250 | 70 | 3 |

| R-744 (CO2) | 3.7 | 220 | 60 | 1 |

| R-32 | 3.2 | 210 | 65 | 675 |

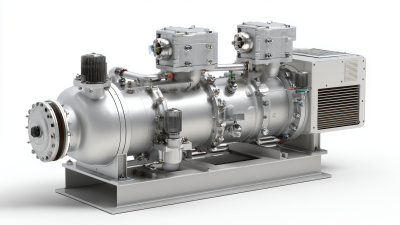

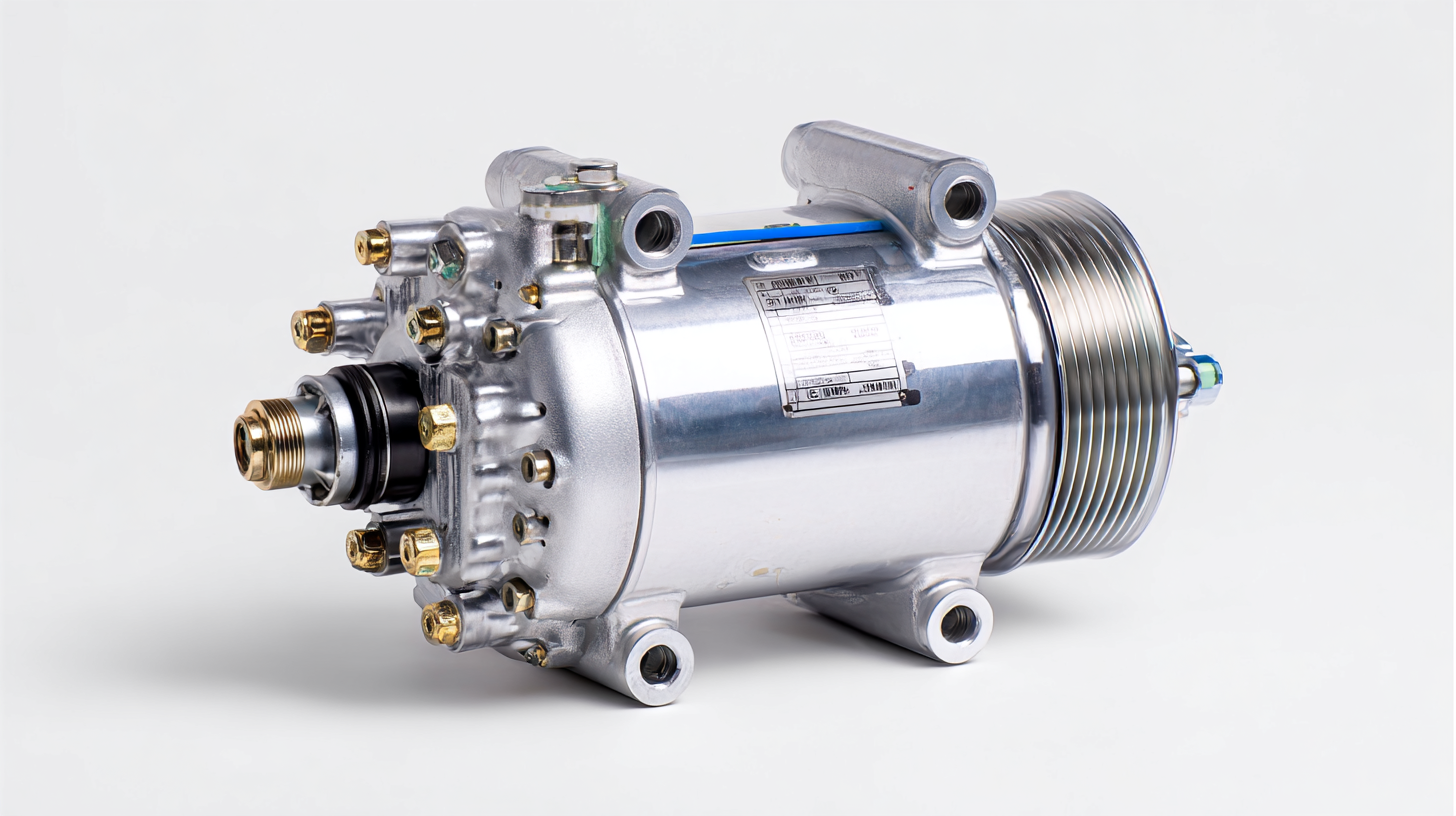

The efficiency of mini fridge compressors is influenced by various technologies, which can significantly impact their energy consumption. Traditional reciprocating compressors have long been the standard, known for their reliability and relatively simple design. However, advancements in compressor technology, such as rotary and inverter-driven compressors, have emerged and are promising enhancements in energy efficiency. Rotary compressors, for example, tend to operate more quietly and have fewer moving parts, which can reduce energy consumption during operation.

Inverter-driven compressors are particularly noteworthy as they adjust the compressor speed according to the cooling demand, leading to substantial energy savings. Unlike traditional compressors that turn on and off frequently, inverters maintain a more consistent temperature and optimize power use, creating a more energy-efficient cooling cycle. Comparative studies highlight that while inverter-driven models may have a higher initial cost, their long-term energy savings can make them a more economical choice. This evolution in compressor technology underscores the importance of understanding the specific mechanisms at play, as they directly correlate to a mini fridge's overall energy efficiency and environmental impact.

Understanding the energy consumption of mini fridges in real-world settings is crucial for evaluating their efficiency. Research has shown that while manufacturers often provide energy usage estimates based on ideal conditions, actual consumption can vary significantly based on factors such as ambient temperature, frequency of door openings, and settings chosen by users. This variability underscores the importance of testing mini fridges in controlled environments that mimic typical household situations to gather accurate data for consumers.

Moreover, advancements in compressor technology and insulation materials have led to notable gains in efficiency over the years. Mini fridges equipped with inverter compressors tend to operate more efficiently, adjusting their power output to match the cooling demand. Real-world data shows that these models can consume up to 30% less energy than traditional compressors. As consumers increasingly prioritize energy savings, understanding these dynamics is essential for making informed choices that reduce both environmental impact and energy bills.