In the realm of HVAC system maintenance, the importance of a Filter Drier cannot be overstated. Industry expert Dr. Emily Cooper, a renowned HVAC systems analyst, emphasizes that “a well-maintained Filter Drier is essential for ensuring the longevity and efficiency of your HVAC system.” Without this crucial component, systems become vulnerable to moisture and debris buildup, leading to performance issues and potential failures.

The Filter Drier plays a critical role in safeguarding the refrigerant circuit, filtering out impurities and absorbing moisture. As the HVAC systems run, contaminants can accumulate, risking damage to sensitive components. By implementing regular maintenance that includes the replacement or cleaning of the Filter Drier, homeowners and businesses alike can significantly extend the life of their HVAC systems.

Not only does the Filter Drier enhance efficiency by ensuring clean refrigerant flow, but it also helps to prevent costly repairs. Regular attention to this often-overlooked component is a prudent investment in the overall health of your HVAC system, underscoring the necessity of incorporating proper maintenance practices.

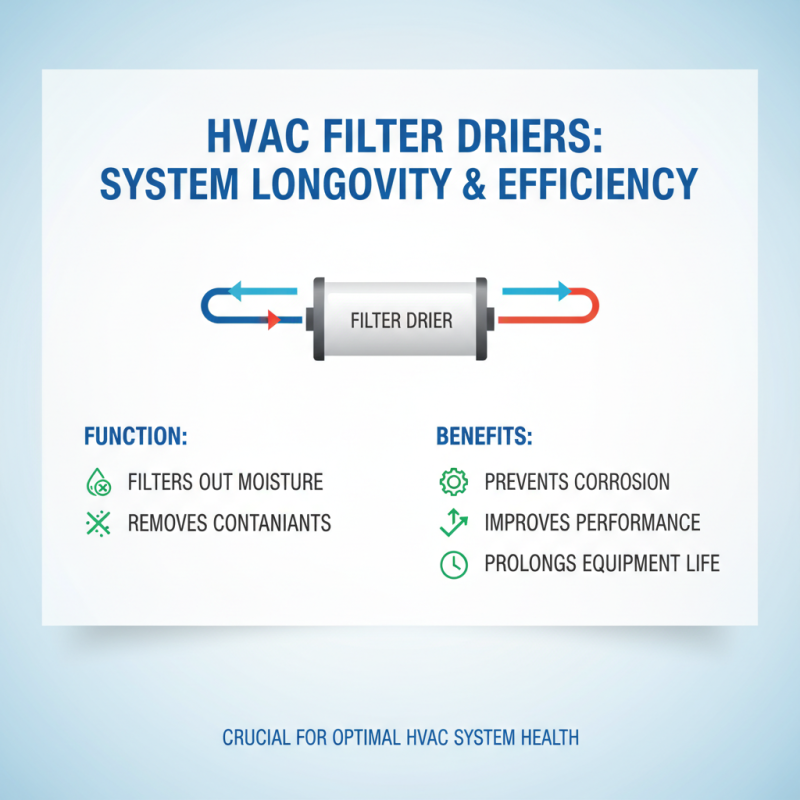

In the realm of HVAC system maintenance, filter driers play a crucial role in ensuring the longevity and efficiency of heating and cooling systems. These components serve as vital checkpoints in the refrigerant cycle, filtering out moisture and contaminants that can accumulate over time. Moisture in the refrigerant can lead to corrosion and deterioration of internal components, resulting in costly repairs and decreased system performance. By effectively removing these harmful impurities, filter driers help maintain optimal system functionality and prolong the lifespan of HVAC equipment.

Additionally, the presence of a filter drier can significantly enhance the energy efficiency of an HVAC system. When contaminants are allowed to build up, they can restrict refrigerant flow and reduce heat exchange efficiency, forcing the system to work harder to achieve the desired temperature. This not only increases energy consumption but can also lead to premature wear and tear. By incorporating filter driers into regular maintenance practices, homeowners and facility managers can ensure their systems operate efficiently, ultimately leading to lower energy bills and a smaller environmental footprint.

Filter driers play a crucial role in the operation of HVAC systems by ensuring that the refrigerant circulated within the system remains clean and uncontaminated. These devices are designed to remove moisture and impurities from the refrigerant before it flows through the system. Moisture is particularly detrimental as it can lead to several issues, such as corrosion within components and the formation of ice, which can obstruct airflow and reduce system efficiency. By absorbing excess moisture, filter driers help maintain optimal performance and extend the life of HVAC equipment.

The operation of filter driers relies on the use of specialized desiccants and filtration mechanisms. When the refrigerant passes through the filter drier, moisture is absorbed by the desiccant material, which effectively traps water molecules. Additionally, the filter component captures particulates and debris, preventing these contaminants from entering the system. This dual-action process contributes to improved reliability and efficiency, as a cleaner refrigerant circulates throughout the HVAC system. Regular maintenance and timely replacement of filter driers are essential to ensure that these devices continue to function effectively, safeguarding the overall health of the HVAC system.

A filter drier plays a crucial role in maintaining the efficiency and longevity of your HVAC system. One of the primary benefits is its ability to remove moisture and contaminants from the refrigerant. Excess moisture can lead to corrosion and damage to various components within the system, causing inefficiencies and potential failures. By installing a filter drier, you ensure that the refrigerant remains clean and dry, promoting optimal system performance and extending its lifespan.

In addition to moisture removal, filter driers also capture dirt, debris, and acid that can accumulate over time. This accumulation can block fluid pathways and result in uneven cooling or heating. By maintaining a clear and healthy refrigerant flow, filter driers enhance energy efficiency, reducing the workload on the compressor and leading to lower energy consumption. Overall, using a filter drier is a smart investment for anyone looking to maintain the reliability and efficiency of their HVAC system while protecting it against potential failures.

| Benefit | Description | Impact on System |

|---|---|---|

| Moisture Removal | Filter driers extract moisture from refrigerant to prevent corrosion and component failure. | Increases longevity of HVAC components. |

| Contaminant Filtration | They filter out contaminants like dirt and debris from the refrigerant. | Enhances overall system efficiency and effectiveness. |

| Enhanced Performance | Maintaining clean refrigerant flow improves system performance. | Results in lower energy consumption and costs. |

| System Protection | Prevents system damage due to inefficient refrigerant operation. | Increases the reliability and lifespan of HVAC systems. |

| Cost-Effectiveness | Lower repair and replacement costs due to better maintenance. | Provides long-term savings on HVAC operations. |

A filter drier plays a crucial role in the maintenance of HVAC systems by ensuring the clean and efficient operation of air conditioning and refrigeration units. Regular maintenance of filter driers can prevent several common issues that arise from moisture and contaminants in the refrigerant. According to the U.S. Department of Energy, nearly 30% of energy consumption in commercial buildings is related to heating, ventilation, and air conditioning. Inefficient systems due to improper filtration can lead to increased energy costs, making filter drier maintenance not just a matter of system longevity, but also of economic efficiency.

One prevalent issue mitigated by maintaining a filter drier is the accumulation of moisture in the refrigeration system. This moisture can lead to corrosion, resulting in refrigerant leaks that undermine system efficiency. The Air Conditioning Contractors of America (ACCA) indicates that up to 20% of an HVAC system’s cooling capacity can be lost due to improper moisture management. Additionally, contaminants like dirt and debris can block the flow of refrigerant, leading to inadequate cooling and heating performance. Regular cleaning or replacement of filter driers can significantly reduce the risk of these problems, thereby enhancing system reliability and reducing maintenance costs over time.

When installing or replacing a filter drier in an HVAC system, it is essential to follow best practices to ensure optimal performance and longevity. First, before installation, always check the system for any leaks and ensure it is clean. A clean system will help the drier function effectively, preventing contaminants from entering the refrigerant circuit. Make sure to select the correct size and type of filter drier for your specific system. This ensures compatibility and efficient moisture and impurity removal.

During installation, it is crucial to position the filter drier correctly. Ideally, it should be installed on the liquid line, where it can adequately remove moisture and particulates before they reach the expansion device. Pay careful attention to the flow direction indicated on the drier, as incorrect installation can lead to system inefficiencies. Additionally, after installation, evacuate the system to remove any trapped air and moisture, and ensure proper refrigerant levels before starting the system. Regular maintenance checks should include inspecting the filter drier for signs of clogging or deterioration to maintain system health.