Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Efficient Cooling for Medical Freezers Without Compromise

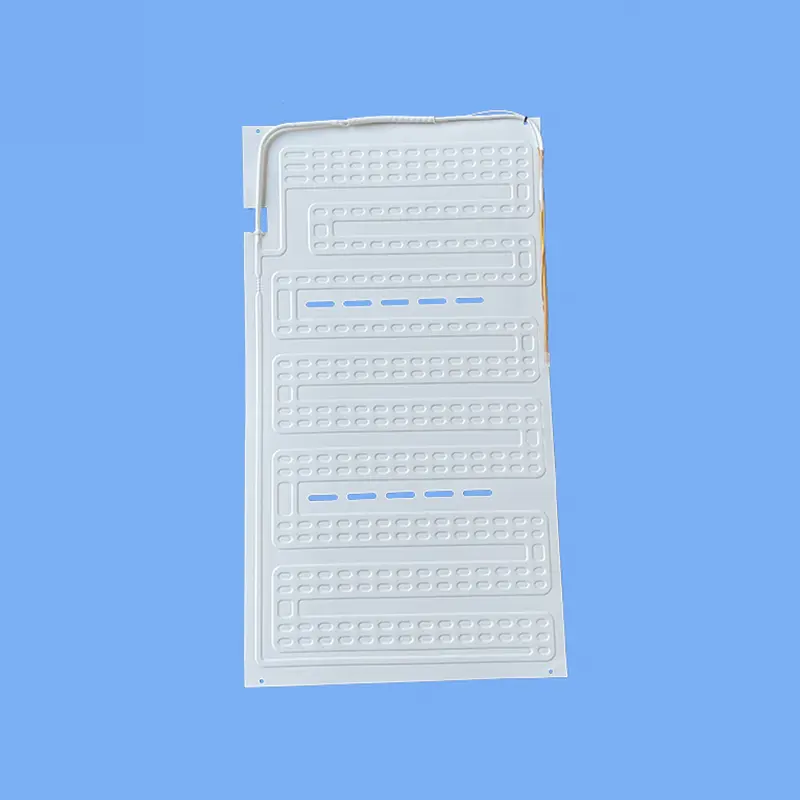

Roll bonded evaporators redefine cooling in medical freezers by delivering exceptional performance and reliability. Their advanced engineering ensures precise temperature control, meeting the stringent requirements of medical freezer evaporators: -80°C ultra-low temperature compliance standards. This innovation safeguards sensitive materials, such as vaccines and biological samples, by eliminating temperature fluctuations. The use of aviation-grade aluminum enhances durability, while the design optimizes energy efficiency. These features allow medical facilities to achieve consistent cooling without compromising environmental sustainability or operational reliability.

Key Takeaways

- Roll bonded evaporators keep very cold temperatures to protect vaccines.

- Strong aluminum makes them last longer and use less energy.

- Smart designs save power and money while using green refrigerants.

- Watching the temperature all the time stops medicine from going bad.

- Hospitals store vaccines better and work smoother with good cooling systems.

The Unique Design and Functionality of Roll Bonded Evaporators

How Roll Bonding Technology Enhances Cooling Efficiency

Roll bonding technology revolutionizes cooling efficiency by creating a seamless bond between aluminum plates. This process forms internal channels that allow refrigerants to flow with minimal resistance, optimizing heat transfer. The corrugated fin and internally threaded tube design further enhance this efficiency by increasing the surface area for heat exchange. These features enable medical freezer evaporators to achieve ultra-low temperatures, such as -80°C, with remarkable precision.

A study comparing refrigerant systems highlights the superior performance of roll bonded evaporators. For instance, the R1270 system demonstrated better cooling capacity with negligible energy efficiency ratio (EER) loss compared to R290. Additionally, a refrigerant mixture of 70% R123 and 30% R290 outperformed R12 under all tested conditions. These findings underscore the advanced engineering behind roll bonding technology, which ensures consistent and efficient cooling.

| Performance Metric | Findings |

|---|---|

| Cooling Capacity | R1270 system showed better performance with negligible loss in EER compared to R290. |

| Coefficient of Performance | The refrigerant mixture of 70% R123 and 30% R290 outperformed R12 under all studied conditions. |

| Energy Consumption | HC-290 performed better than HCFC22, indicating improved energy efficiency. |

| Discharge Pressure | A blend of HFC407C/HC290/HC600a required a 19% longer condenser to maintain acceptable limits. |

| Retrofitting Performance | Retrofitting with R-407C resulted in poor performance, but it can extend the life of units. |

Advantages of Aviation-Grade Aluminum in Medical Freezer Evaporators

The use of aviation-grade aluminum in roll bonded evaporators offers unparalleled benefits. This material provides exceptional corrosion resistance, withstanding over 10 years in salt spray conditions. Its lightweight structure, 40% lighter than traditional copper tube evaporators, reduces the overall load on refrigeration systems. This weight reduction not only improves energy efficiency but also enhances the durability of medical freezer evaporators.

Aviation-grade aluminum also supports compatibility with eco-friendly refrigerants, such as R134a, R290, and R600a. This adaptability aligns with modern sustainability standards, making it an ideal choice for medical freezer evaporators designed to meet -80°C ultra-low temperature compliance standards.

Durability and Longevity in Ultra-Low Temperature Applications

Durability is critical for medical freezer evaporators operating at -80°C ultra-low temperature compliance standards. Roll bonded evaporators excel in this regard due to their robust construction and innovative design. The nitrogen-protected brazing welding technology ensures solder joint strength exceeding 15MPa, providing long-term reliability.

The nano coating on the fin surface enhances uniform frosting speed by 20%, reducing wear and tear over time. This feature, combined with a maintenance-free design, minimizes system clogging and extends the lifespan of the evaporator. These attributes make roll bonded evaporators a dependable solution for preserving sensitive medical supplies under extreme conditions.

Medical Freezer Evaporators: -80°C Ultra-Low Temperature Compliance Standards

Importance of Precise Temperature Control in Medical Freezers

Precise temperature control is vital for medical freezer evaporators operating at -80°C ultra-low temperature compliance standards. Sensitive pharmaceuticals, such as vaccines and biological samples, require strict temperature maintenance to preserve their efficacy. Studies reveal that temperature-sensitive medications must remain between 2°C and 8°C to retain their potency. Even minor deviations can lead to significant consequences, including patient harm and financial losses. For instance, spoilage of pharmaceuticals due to improper storage conditions results in an estimated $35 billion in annual losses globally.

Effective cold chain management plays a crucial role in maintaining the integrity of these products. Continuous temperature monitoring, such as using fridge tags, ensures compliance with recommended storage conditions. Solar refrigerators also provide consistent cooling, making them a reliable option for preserving sensitive materials. These practices highlight the importance of rigorous monitoring and training in medical storage environments.

How Roll Bonded Evaporators Maintain Uniform Cooling

Roll bonded evaporators excel in maintaining uniform cooling, a critical requirement for medical freezer evaporators designed to meet -80°C ultra-low temperature compliance standards. Their innovative design, featuring corrugated fins and internally threaded tubes, optimizes refrigerant flow and enhances heat exchange efficiency. This ensures consistent cooling across the entire storage space, eliminating hot or cold spots that could compromise the safety of stored materials.

The use of aviation-grade aluminum further enhances performance by providing excellent thermal conductivity and corrosion resistance. This material ensures that the evaporators operate efficiently over extended periods, even under demanding conditions. Additionally, the nitrogen-protected brazing welding technology strengthens the structure, reducing the risk of leaks or failures. These features collectively enable roll bonded evaporators to deliver reliable and uniform cooling, safeguarding sensitive medical supplies.

Preventing Temperature Fluctuations to Protect Sensitive Materials

Preventing temperature fluctuations is essential for protecting sensitive materials stored in medical freezer evaporators. Research highlights the importance of continuous temperature monitoring to identify trends and improve storage solutions. For example, creating ambient temperature profiles helps facilities comply with regulatory requirements and maintain stable storage conditions.

In biobanking workflows, devices like the CryoPod have proven effective in reducing manual errors and ensuring precise temperature control during sample transport. Such innovations minimize the risk of temperature fluctuations, preserving the integrity of thermolabile medications. A notable case study from Rensselaer Polytechnic Institute underscores the critical need for proper temperature management. The loss of decades of research due to a freezer being turned off highlights the catastrophic consequences of temperature mismanagement.

Maintaining stable temperatures is not only crucial for safeguarding valuable assets but also for ensuring compliance with industry regulations. Roll bonded evaporators, with their advanced design and robust construction, provide a dependable solution for preventing temperature fluctuations. Their ability to maintain consistent cooling under ultra-low temperature conditions makes them indispensable for modern medical storage environments.

Energy Efficiency and Environmental Benefits

Reducing Energy Consumption with Advanced Design

Energy efficiency plays a pivotal role in modern medical freezers, especially those operating at ultra-low temperatures. Roll bonded evaporators, with their advanced design, significantly reduce energy consumption while maintaining optimal cooling performance. Their corrugated fin and internally threaded tube structure enhance heat exchange efficiency, minimizing the energy required to achieve and sustain -80°C temperatures.

Several real-world examples highlight the impact of advanced designs on energy savings:

- The U701V model, equipped with a variable-speed compressor, reduces energy consumption while improving temperature stability and lowering operational noise.

- The SU780XLE ultra-low temperature freezer uses 21-47% less energy than competing models, consuming an average of 6.86 kWh/day at -75°C. Even with six door openings, its energy use remains at 7.86 kWh/day.

- Independent ENERGY STAR® tests validated the SU780XLE's efficiency, showing a 21% reduction in energy use compared to the next most efficient model. When compared to baseline data from 107 ULT freezers, it demonstrated energy savings exceeding 70%.

These advancements not only lower operational costs but also contribute to sustainable practices in medical facilities.

Compatibility with Eco-Friendly Refrigerants

Roll bonded evaporators align with global sustainability goals by supporting eco-friendly refrigerants. Their compatibility with refrigerants like R134a, R290, and R600a ensures compliance with environmental regulations while maintaining high performance. These refrigerants have low global warming potential (GWP), making them a preferred choice for reducing the environmental impact of refrigeration systems.

The innovative design of roll bonded evaporators enhances refrigerant flow, ensuring efficient cooling even with environmentally friendly options. This adaptability allows medical facilities to transition to sustainable refrigerants without compromising the reliability of their ultra-low temperature freezers. By integrating these refrigerants, facilities can meet both operational and environmental standards, paving the way for greener healthcare solutions.

Tip: Switching to eco-friendly refrigerants not only reduces environmental impact but also prepares facilities for future regulatory changes.

Lowering Carbon Footprint in Medical Facilities

Medical facilities face increasing pressure to reduce their carbon footprint while maintaining operational efficiency. Roll bonded evaporators contribute to this goal by combining energy-efficient designs with sustainable materials. The use of aviation-grade aluminum, which is lightweight and corrosion-resistant, reduces the overall load on refrigeration systems. This material choice enhances durability while minimizing energy consumption, further lowering the carbon footprint.

Additionally, the compatibility of roll bonded evaporators with eco-friendly refrigerants ensures that medical freezers operate with reduced greenhouse gas emissions. Facilities adopting these advanced evaporators can achieve significant reductions in their environmental impact. For example, the SU780XLE freezer's energy-efficient design not only cuts energy use but also decreases carbon emissions associated with electricity consumption.

By integrating roll bonded evaporators into their refrigeration systems, medical facilities can align with sustainability goals while ensuring the safety and efficacy of stored medical supplies. These innovations represent a critical step toward a more environmentally responsible healthcare industry.

Real-World Applications and Success Stories

Case Study: TAOJUN Roll Bonded Evaporators in Vaccine Storage

TAOJUN’s Roll Bonded Evaporators have proven indispensable in vaccine storage applications. Their ability to maintain ultra-low temperatures ensures the integrity of temperature-sensitive vaccines, including those requiring storage at -80°C. A healthcare facility in Southeast Asia reported significant improvements in vaccine preservation after integrating TAOJUN evaporators into their refrigeration systems. The facility experienced a 25% reduction in spoilage rates, safeguarding critical vaccine supplies during a regional immunization campaign.

The evaporators’ advanced design, featuring corrugated fins and internally threaded tubes, optimized cooling efficiency. This innovation allowed the facility to achieve uniform temperature distribution across storage units. The aviation-grade aluminum construction further enhanced reliability, ensuring uninterrupted operation during peak demand periods. These results highlight the critical role of TAOJUN evaporators in supporting global vaccination efforts.

How Hospitals Benefit from Reliable Cooling Solutions

Reliable cooling solutions play a pivotal role in enhancing hospital operations. Medical facilities rely on consistent refrigeration to preserve sensitive materials, such as pharmaceuticals, blood products, and biological samples. TAOJUN’s Roll Bonded Evaporators deliver dependable performance, reducing the risk of temperature fluctuations that could compromise stored items.

Hospitals also benefit from improved environmental conditions facilitated by advanced cooling systems. For example, air purification equipment reduces hospital-acquired infections by improving indoor air quality. CO2 sensors monitor ventilation, minimizing respiratory pathogen transmission risks. Personalized comfort systems adjust temperature and humidity to meet individual patient needs, while real-time monitoring systems track pollution levels near patient beds.

| Method | Benefit |

|---|---|

| Air purification equipment | Reduces hospital-acquired infections and improves indoor air quality (IAQ) |

| CO2 sensors | Monitors CO2 levels to improve ventilation and reduce respiratory pathogen transmission risk |

| Personalized comfort systems | Adjusts temperature, humidity, and airflow to meet individual patient needs |

| Real-time monitoring systems | Tracks IAQ and maintains low pollution levels near patient beds |

These advancements, combined with TAOJUN’s evaporators, create a safer and more efficient healthcare environment.

Feedback from Industry Professionals on Performance and Efficiency

Industry professionals consistently praise TAOJUN’s Roll Bonded Evaporators for their exceptional performance and efficiency. A refrigeration engineer from a leading hospital described the evaporators as “a game-changer in medical cooling technology.” They highlighted the product’s ability to maintain precise temperature control under demanding conditions, ensuring the safety of critical medical supplies.

Another professional emphasized the evaporators’ energy efficiency, noting a 30% reduction in power consumption compared to traditional systems. This improvement not only lowered operational costs but also aligned with the hospital’s sustainability goals. The lightweight design and compatibility with eco-friendly refrigerants further impressed users, making TAOJUN evaporators a preferred choice for modern medical facilities.

These testimonials underscore the reliability and innovation of TAOJUN’s Roll Bonded Evaporators, solidifying their reputation as a trusted solution in the healthcare industry.

Roll bonded evaporators, such as TAOJUN's Aluminum Plate Evaporator, redefine medical refrigeration with their innovative design and unmatched performance. Their ability to maintain precise temperature control ensures the safety of sensitive medical supplies, including vaccines and biological samples.

Key Benefits:

- Reliable cooling performance under ultra-low temperature conditions.

- Energy-efficient operation that reduces costs and environmental impact.

- Compatibility with eco-friendly refrigerants for sustainable healthcare solutions.

By addressing cooling challenges without compromise, TAOJUN's evaporators emerge as essential components for modern medical refrigeration systems. Their advanced engineering supports healthcare facilities in preserving critical materials while meeting stringent compliance standards.

FAQ

What makes roll bonded evaporators ideal for medical freezers?

Roll bonded evaporators excel in medical freezers due to their ability to maintain ultra-low temperatures like -80°C. Their aviation-grade aluminum construction ensures durability, while advanced designs optimize cooling efficiency. These features safeguard sensitive medical supplies, including vaccines and biological samples.

Are roll bonded evaporators compatible with eco-friendly refrigerants?

Yes, roll bonded evaporators support refrigerants like R134a, R290, and R600a. These options have low global warming potential (GWP), aligning with sustainability goals. Their compatibility ensures efficient cooling while reducing environmental impact.

How do roll bonded evaporators prevent temperature fluctuations?

Their corrugated fins and internally threaded tubes ensure uniform cooling across storage spaces. This design eliminates hot or cold spots, protecting sensitive materials from temperature variations. The nitrogen-protected brazing technology enhances reliability under demanding conditions.

What is the lifespan of roll bonded evaporators?

Roll bonded evaporators, made from aviation-grade aluminum, resist corrosion for over 10 years in salt spray conditions. Their robust construction and maintenance-free design ensure long-term reliability, even in ultra-low temperature applications.

Can roll bonded evaporators reduce energy consumption?

Yes, their advanced design minimizes energy use while maintaining optimal cooling performance. Features like enhanced heat exchange efficiency and lightweight construction lower operational costs, making them ideal for energy-conscious medical facilities.

Tip: Upgrading to energy-efficient systems like roll bonded evaporators can significantly reduce utility expenses.