Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How AC Refrigerator Motors Help Maintain Consistent Airflow

AC refrigerator motors play a central role in modern cooling systems. These motors power fans and compressors, facilitating the movement of air and controlling temperature with precision. Their efficiency ensures consistent airflow, which contributes to healthier indoor environments.

Recent trends highlight advancements in motor technology:

- The market is expanding due to a focus on energy efficiency.

- Regulations are encouraging manufacturers to innovate.

- Inverter technology enables variable-speed motors for optimized cooling.

Various motor types are gaining traction, including:

- AC induction motors and DC brushless motors.

- DC inverter motors, favored for energy-saving and compact designs.

Key Takeaways

- AC fridge motors keep airflow steady, making air cleaner and comfy.

- Taking care of ACs, like changing filters, helps motors work better and last longer.

- Putting vents and fans in smart spots improves airflow and stops stuffy air and hot areas.

- Using better motors, like the Taojun HVAC FAN, saves energy and moves air well.

- Learning about motors helps people pick the best ones for healthier homes.

Understanding AC Refrigerator Motors

Components of AC Refrigerator Motors

AC refrigerator motors consist of several key components that work together to ensure efficient operation. Each part plays a specific role in driving airflow and maintaining temperature control. The primary components include:

- Stator and Rotor: The stator generates a magnetic field, while the rotor rotates within this field to produce mechanical energy.

- Windings: These copper or aluminum coils conduct electricity, creating the magnetic field necessary for motor operation.

- Bearings: Bearings support the rotor, reducing friction and ensuring smooth rotation.

- Housing: This protective casing shields the internal components from dust, moisture, and physical damage.

- Control Electronics: Advanced motors, such as Electronically Commutated Motors (ECMs), include control circuits for precise speed and efficiency adjustments.

Different motor types, such as Shaded Pole (SP), Permanent Split Capacitor (PSC), and ECM motors, vary in their design and performance. SP motors are simple and reliable but less efficient. PSC motors offer better efficiency and reversibility. ECM motors stand out for their ability to maintain constant speed and airflow under varying conditions, making them ideal for modern cooling systems.

Tip: Choosing the right motor type depends on the specific application and desired balance between cost, efficiency, and performance.

How Motors Drive Fans and Compressors for Air Circulation

AC refrigerator motors play a pivotal role in driving both fans and compressors, ensuring consistent airflow and temperature regulation. The motor powers the fan blades, which circulate air across the evaporator coils. This process cools the air and distributes it evenly throughout the space.

For compressors, the motor compresses refrigerant gas, increasing its pressure and temperature. This high-pressure gas then flows through the condenser coils, releasing heat and enabling the cooling cycle to continue. The seamless operation of these components depends on the motor's ability to maintain steady performance.

ECM motors excel in this regard. Unlike SP and PSC motors, ECM motors can adjust their speed based on load requirements. This capability ensures optimal airflow even under restricted conditions, such as clogged filters or blocked vents. Additionally, ECM motors operate more quietly, avoiding the 60-cycle hum typical of SP and PSC motors.

Note: Regular maintenance of fans and compressors can enhance motor performance and prolong the lifespan of the entire cooling system.

Benefits of Consistent Airflow

Enhanced Air Quality and Pollutant Reduction

Consistent airflow plays a vital role in improving indoor air quality by reducing the concentration of pollutants. When air circulates effectively, it prevents the buildup of harmful particles such as dust, pollen, and volatile organic compounds (VOCs). Systems powered by an AC Refrigerator Motor ensure that air moves continuously, allowing filtration mechanisms to capture contaminants more efficiently.

A study comparing different ventilation systems highlights the impact of consistent airflow on pollutant reduction:

| Ventilation System Type | Reduction in 0.3-2.0 Micron Particles | Reduction in Total Volatile Compounds (TVOC) |

|---|---|---|

| Central-Fan-Integrated Supply (CFIS) | House 1: 85% House 2: 73% | CFIS: 47% reduction |

| Energy Recovery Ventilation (ERV) | N/A | ERV: 57% reduction |

| Exhaust System | N/A | Increased TVOC by 37% (House 1) Increased TVOC by 18% (House 2) |

The table demonstrates that systems like CFIS and ERV, which rely on consistent airflow, significantly reduce pollutants. In contrast, exhaust systems without proper circulation can increase VOC levels. By maintaining steady air movement, AC Refrigerator Motors contribute to healthier indoor environments.

Tip: Regularly replacing air filters enhances pollutant reduction and ensures optimal motor performance.

Even Temperature Distribution for Improved Comfort

Uneven temperature distribution can lead to discomfort, especially in larger spaces. Consistent airflow ensures that treated air reaches every corner of a room, eliminating cold or hot spots. AC Refrigerator Motors excel in driving fans that distribute air evenly, creating a balanced indoor climate.

Statistical findings reveal the relationship between temperature distribution and comfort:

| AC Setpoint (°C) | Temperature Distribution | Comfort Level |

|---|---|---|

| 18 | Uniform | High |

| 20 | Uneven | Low |

| 25 | Uniform | High |

The data shows that uniform temperature distribution correlates with higher comfort levels. Motors capable of maintaining steady airflow ensure that air circulates effectively, preventing temperature imbalances. This feature is particularly beneficial in homes and offices where comfort is a priority.

Prevention of Stale Air and Hotspots Indoors

Stale air and hotspots often result from poor ventilation and inadequate air circulation. These issues not only compromise comfort but also create an environment conducive to mold growth and unpleasant odors. Consistent airflow prevents such problems by continuously refreshing indoor air and maintaining a stable temperature.

AC Refrigerator Motors, with their ability to drive fans and compressors efficiently, play a crucial role in this process. By ensuring that air moves freely, they eliminate stagnant zones and promote a healthier living space. This functionality is especially important in areas with limited natural ventilation, such as basements or enclosed rooms.

Note: Strategic placement of vents and fans can further enhance airflow, ensuring that no area is left untreated.

Energy Efficiency in Modern AC Refrigerator Motors

Features of energy-efficient motor designs

Modern AC refrigerator motors prioritize energy efficiency to reduce power consumption and environmental impact. These motors incorporate advanced designs that optimize performance while minimizing waste. Key features include:

- Variable-Speed Operation: Motors with variable-speed capabilities adjust their performance based on cooling demands. This feature prevents energy overuse during low-load conditions.

- Improved Insulation: Enhanced insulation materials reduce heat loss, ensuring motors operate at peak efficiency.

- High-Efficiency Ratings: Motors achieve efficiency levels that align with ENERGY STAR® standards, offering significant savings in energy costs.

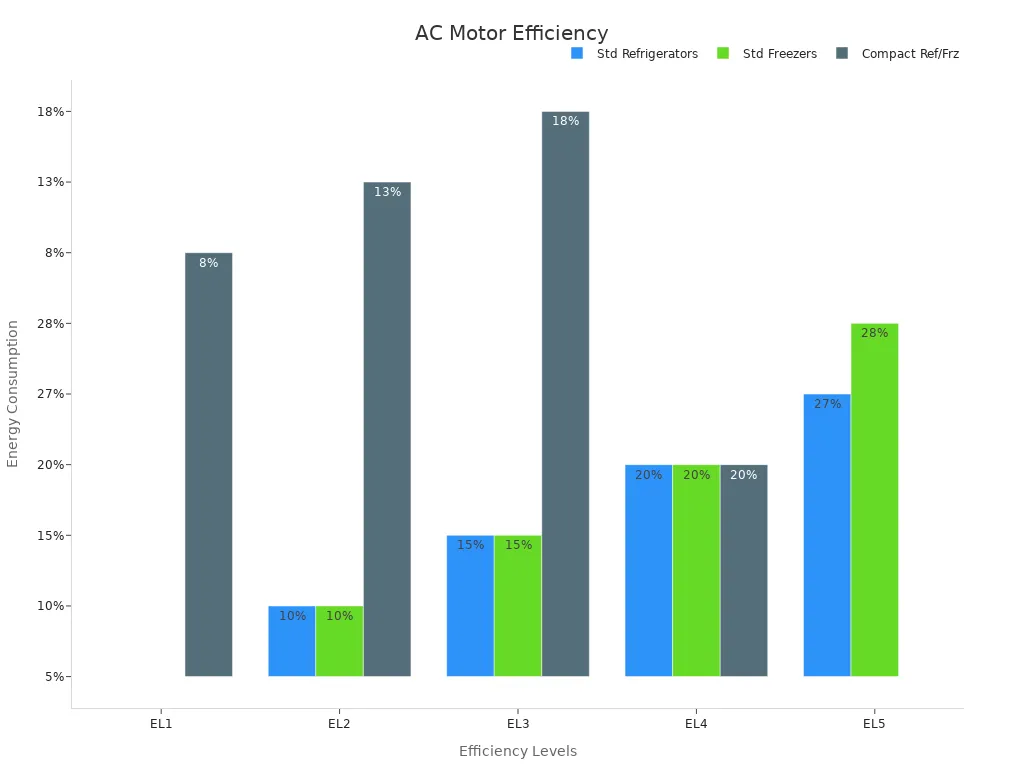

The U.S. Department of Energy (DOE) has proposed new energy conservation standards for residential refrigerators and freezers. Efficiency levels are categorized in increments, with Trial Standard Level 5 (TSL5) offering the highest savings and reduced CO2 emissions.

| Product Class (AV, ft) | EL 1 | EL 2 | EL 3 | EL 4 | EL 5 |

|---|---|---|---|---|---|

| Standard-Size Refrigerator | 5% | 10% | 15% | 20% | 27% |

| Standard-Size Freezers | 5% | 10% | 15% | 20% | 28% |

| Compact Refrigerators and Freezers | 8% | 13% | 18% | 20% | N/A |

These advancements ensure that AC refrigerator motors deliver consistent airflow while maintaining energy efficiency.

Smart motor technology and its role in airflow optimization

Smart motor technology revolutionizes airflow optimization by integrating electronic controls and real-time adjustments. Unlike traditional mechanical fans, electronic fans powered by smart motors offer superior performance and flexibility.

| Feature | Electronic Fans | Mechanical Fans |

|---|---|---|

| Power Source | Electrically powered | Belt-driven from engine |

| Speed Regulation | Independent, real-time adjustment | Proportional to engine RPM |

| Energy Efficiency | Higher under low loads | Lower under low loads |

| Cooling Capacity | Sufficient during high loads | Limited under varying conditions |

| Size and Weight | Smaller and lighter | Larger and heavier |

| Operation After Shutdown | Yes, prevents thermal damage | No |

Smart motors enable precise speed regulation, ensuring optimal airflow under varying conditions. Their ability to operate independently of engine RPM enhances energy efficiency, especially during low-load scenarios. Additionally, these motors prevent thermal damage by continuing operation after system shutdown.

By integrating smart motor technology, AC refrigerator motors achieve consistent airflow and improved cooling capacity. This innovation enhances indoor comfort while reducing energy consumption, making it a valuable addition to modern cooling systems.

Practical Tips for Optimizing Air Circulation

Importance of regular maintenance for AC systems

Regular maintenance ensures optimal airflow and prolongs the lifespan of cooling systems. Neglecting upkeep can lead to clogged filters, reduced efficiency, and uneven air distribution. Key maintenance tasks include replacing air filters, scheduling seasonal checkups, and cleaning around the unit.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Change Air Filters | Every 1-3 months | Prevents mold and mildew buildup, ensures proper airflow |

| Schedule Seasonal Checkups | Annually | Maintains system efficiency and identifies potential issues |

| Clean Around the Unit | Regularly | Prevents dust buildup that can hinder airflow |

Replacing air filters prevents contaminants from accumulating and obstructing airflow. Seasonal checkups allow technicians to identify and resolve issues before they escalate. Cleaning around the unit reduces dust and debris that can block vents or fans. These practices collectively enhance the performance of AC Refrigerator Motors, ensuring consistent air circulation.

Tip: Set reminders for maintenance tasks to avoid delays and ensure uninterrupted airflow.

Strategic placement of vents and fans

The placement of vents and fans significantly impacts airflow efficiency. Proper positioning ensures treated air reaches all areas of a room, eliminating stagnant zones and improving indoor air quality. Research studies highlight the importance of strategic placement in optimizing ventilation.

| Study | Findings |

|---|---|

| Gilkeson et al. | Cross natural ventilation improved pathogen dilution in hospital wards. |

| Qian et al. | Larger openings with fans enhanced ventilation performance. |

| Ai et al. | Mechanical ventilation reduced aerosol spread in cross-infection cases. |

| Xiaoping et al. | Displacement ventilation minimized inhalation of smaller droplets. |

| Akbari & Salmanzadeh | Optimal placement of air cleaners improved indoor air quality. |

Positioning vents near ceilings and fans at strategic angles maximizes airflow. Cross ventilation techniques, such as placing vents on opposite walls, promote air movement and reduce pollutant concentration. In offices or homes, displacement ventilation minimizes the spread of contaminants, creating a healthier environment.

Note: Consult HVAC professionals to determine the best placement for vents and fans based on room layout and airflow requirements.

Upgrading to advanced motors like Taojun HVAC FAN for better performance

Upgrading to advanced motors enhances air circulation and energy efficiency. The Taojun HVAC FAN exemplifies modern motor technology with features designed for superior performance. Its high-efficiency impeller and motor generate substantial air volume, ensuring rapid and consistent airflow.

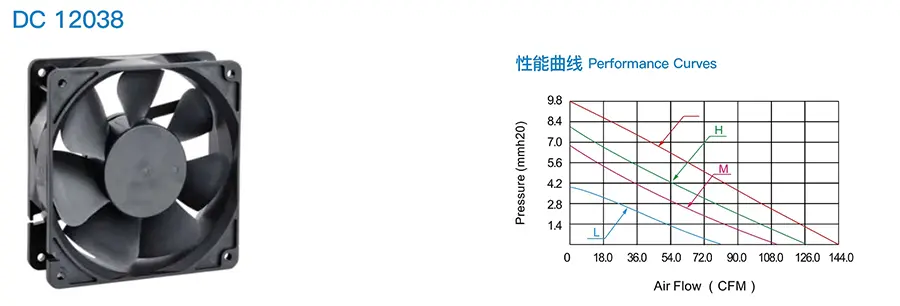

The FAN operates quietly, making it ideal for residential and commercial spaces where noise reduction is essential. Its speed-adjustment capability allows users to tailor air circulation to specific needs, preventing over-cooling or overheating. Models like the FAN DC 12038 offer durable construction and adaptability to various voltage requirements, making them suitable for diverse applications.

By integrating the Taojun HVAC FAN into cooling systems, homeowners and businesses can achieve optimal airflow while reducing energy consumption. This upgrade ensures consistent air distribution, improved comfort, and enhanced indoor air quality.

Tip: Consider advanced motors like Taojun HVAC FAN for long-term savings and better air circulation.

AC refrigerator motors play a vital role in ensuring consistent airflow, which enhances air quality and indoor comfort. Modern innovations, such as those found in Taojun HVAC products, provide energy-efficient solutions that optimize air circulation. By understanding the importance of these motors and applying practical strategies, homeowners can create healthier living spaces. Upgrading to advanced motor technologies further improves performance, making it a worthwhile investment for long-term comfort and efficiency.

FAQ

What is the primary function of an AC refrigerator motor?

An AC refrigerator motor powers fans and compressors to regulate airflow and temperature. It ensures consistent air circulation, which improves indoor comfort and air quality. These motors are essential for maintaining the efficiency of cooling systems in residential, commercial, and industrial settings.

How does consistent airflow improve indoor air quality?

Consistent airflow prevents the buildup of pollutants like dust and VOCs. It allows filtration systems to capture contaminants more effectively. This process creates a healthier indoor environment by reducing allergens and maintaining fresh air circulation throughout the space.

Why are energy-efficient motors important?

Energy-efficient motors reduce power consumption and operating costs. They also minimize environmental impact by lowering carbon emissions. Advanced designs, such as variable-speed operation and improved insulation, ensure optimal performance while conserving energy.

How can homeowners optimize air circulation?

Homeowners can optimize air circulation by regularly maintaining their AC systems, strategically placing vents and fans, and upgrading to advanced motors like the Taojun HVAC FAN. These steps ensure consistent airflow, prevent hotspots, and enhance overall comfort.

What makes the Taojun HVAC FAN a good choice?

The Taojun HVAC FAN offers high-efficiency air circulation, low noise operation, and customizable speed settings. Its durable construction and advanced features make it suitable for various applications. It ensures consistent airflow, improves comfort, and reduces energy consumption, making it a reliable investment.