Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How Single Tube Copper Accumulator Improves Energy Efficiency in Cooling Systems

The Single Tube Copper Accumulator plays a vital role in boosting energy efficiency in cooling systems. Its advanced design delivers superior heat transfer, prevents refrigerant flooding, and ensures better oil management. These features reduce compressor wear, maximize system reliability, and lower operational costs for businesses.

Key Takeaways

- The Single Tube Copper Accumulator improves cooling system efficiency by preventing liquid refrigerant from reaching the compressor and enhancing heat transfer with copper’s high thermal conductivity.

- It supports proper oil return to the compressor, reducing wear and extending the system’s lifespan, which lowers maintenance needs and operational costs.

- Its lightweight, durable design makes installation easier and adapts to various industries, offering reliable performance and long-term savings.

Single Tube Copper Accumulator: Function and Role

What Is a Single Tube Copper Accumulator

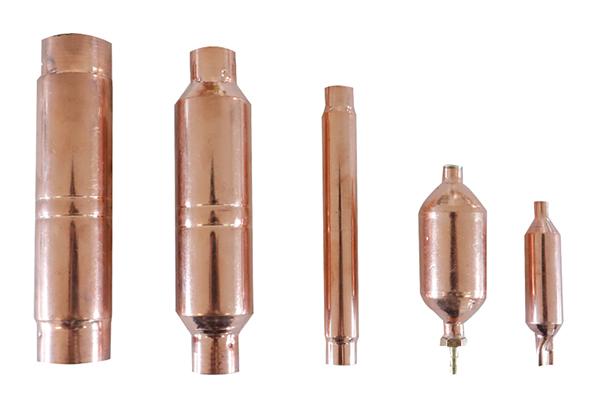

A Single Tube Copper Accumulator is a specialized component used in cooling and refrigeration systems. It acts as a reservoir for excess refrigerant, ensuring that only vapor returns to the compressor. This design helps maintain system stability and prevents liquid refrigerant from causing damage. Manufacturers use copper for its high thermal conductivity, which improves heat transfer and enhances overall efficiency. The accumulator’s lightweight construction also makes installation and maintenance easier for technicians.

Technical guidelines define several key characteristics for optimal performance:

- The accumulator must hold at least 50% of the system’s refrigerant charge.

- It should operate with minimal pressure drop, ideally not exceeding a 0.5°F equivalent.

- The device must return liquid at proper rates under different load conditions.

- Install the accumulator after the suction line filter and insulate it to prevent condensation.

- For vertical models, position it close to the compressor and protecT Copper Fittings.

- For horizontal models, align the inlet with the return tube and maintain a straight run to the compressor.

- Additional features may include connections for liquid injection and hot gas bypass.

- Support the unit with angle brackets attached to end caps.

- Safety features, such as fusible elements, provide venting during fire conditions.

How It Works in Cooling Systems

The Single Tube Copper Accumulator plays a crucial role in maintaining the efficiency and reliability of cooling systems. It acts as a buffer, stabilizing the volume of liquid refrigerant within the system. Research on passive two-phase liquid cooling systems shows that an accumulator helps maintain consistent thermal performance, especially when system loads fluctuate. In smaller systems, the accumulator’s relative size becomes more significant, further improving thermal stability and efficiency.

By managing refrigerant flow, the Single Tube Copper Accumulator prevents liquid from reaching the compressor. This protection reduces the risk of mechanical failure and extends the lifespan of the system. The accumulator also ensures that oil returns to the compressor at the correct rate, supporting smooth operation. These functions make the Single Tube Copper Accumulator an essential component for modern cooling and refrigeration applications.

Solving Energy Efficiency Challenges with Single Tube Copper Accumulator

Preventing Refrigerant Flooding

Refrigerant flooding poses a significant risk to the performance and longevity of cooling systems. When liquid refrigerant enters the compressor, it can cause mechanical damage and reduce system efficiency. The Single Tube Copper Accumulator acts as a safeguard by capturing excess liquid refrigerant and allowing only vapor to return to the compressor. This process stabilizes system operation and prevents costly breakdowns.

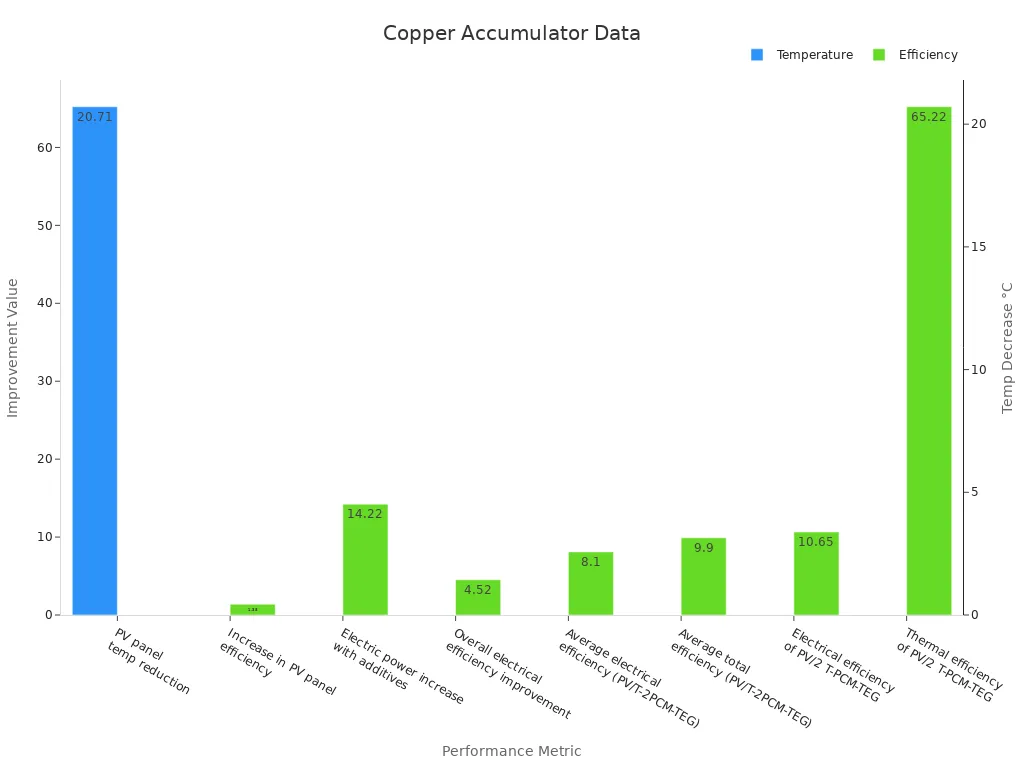

A range of technical studies highlights the effectiveness of copper tube accumulators in managing refrigerant flow. For example, research on serpentine copper tubes in hybrid cooling systems demonstrates a reduction in surface temperatures by up to 20.71 °C and an increase in overall electrical efficiency by 4.52%. These improvements result from the accumulator’s ability to enhance heat dissipation and maintain optimal refrigerant states.

| Performance Metric | Quantitative Improvement |

|---|---|

| PV panel surface temperature reduction | Up to 20.71 °C decrease |

| Increase in PV panel efficiency | 1.38% |

| Electric power increase with thermal conductivity additives | 14.22% increase |

| Overall electrical efficiency improvement | 4.52% |

| Average electrical efficiency increase (PV/T-2PCM-TEG system) | 8.1% higher than PV/T-TEG system |

| Average total efficiency increase (PV/T-2PCM-TEG system) | 9.9% higher than PV/T-TEG system |

| Electrical efficiency of PV/2 T-PCM-TEG system | 10.65% |

| Thermal efficiency of PV/2 T-PCM-TEG system | 65.22% |

These results confirm that integrating a copper accumulator into the cooling circuit not only prevents refrigerant flooding but also delivers measurable gains in energy efficiency.

Enhancing Oil Management

Proper oil management is essential for the smooth operation of any refrigeration or cooling system. The Single Tube Copper Accumulator supports this by ensuring that oil returns to the compressor at the correct rate. This function maintains lubrication, which is critical for reducing friction and preventing wear on moving parts.

Technical benchmarks and case studies provide further insight into the benefits of copper tube designs:

- Tay NHS et al. (2013) demonstrated that copper tubes in PCM thermal energy storage systems improve heat transfer and energy efficiency.

- Seddegh S et al. (2016) found that the orientation and design of copper tubes in shell-and-tube units directly influence thermal storage efficiency.

- Christopher S et al. (2020) highlighted efficiency improvements in evacuated tube collectors using copper-based finned tubes.

- Y.L. Shabtay et al. (2014) showed that combining copper tubes with high-conductivity materials enhances thermal storage and energy efficiency.

- J. Shon et al. (2014) reported better heat storage rates and energy efficiency in automotive systems with copper tube heat exchangers.

- K. Merlin et al. (2016) discussed how improved tube and shell designs, including copper, boost latent heat storage performance.

Note: These studies consistently show that copper tube accumulators optimize oil return, minimize oil carryover, and maintain system cleanliness. This leads to improved heat transfer and reduced maintenance needs.

Reducing Compressor Wear and Extending Lifespan

Compressor reliability stands at the heart of any efficient cooling system. The Single Tube Copper Accumulator plays a crucial role in protecting the compressor from stress and premature failure. By preventing liquid refrigerant from reaching the compressor and ensuring proper oil return, the accumulator reduces mechanical wear and extends the operational life of the compressor.

Industry benchmarks indicate several key advantages:

- Longer compressor life due to reduced stress and improved lubrication.

- Lower system load as the accumulator recovers and utilizes heat more efficiently.

- Energy savings from optimized refrigerant handling and reduced compressor workload.

- Minimal oil carryover, which prevents performance losses and refrigerant contamination.

- Enhanced compressor protection by maintaining proper oil levels.

- Reduced maintenance requirements due to high-efficiency oil separation.

- Improved system reliability and extended operational life.

These benefits translate into lower operating costs and fewer service interruptions. The compact and durable design of the Single Tube Copper Accumulator supports long-term use and easy installation, making it a preferred choice for professionals seeking to maximize system uptime and efficiency.

Key Benefits for System Performance and Cost

Improved Energy Efficiency and Heat Transfer

Copper’s high thermal conductivity gives cooling systems a significant advantage. The Single Tube Copper Accumulator uses this property to transfer heat quickly and efficiently. This rapid heat exchange helps maintain optimal temperatures throughout the system. As a result, energy consumption drops, and the system operates at peak performance. Many engineers choose copper accumulators for their ability to handle temperature fluctuations without losing efficiency.

Tip: Systems with better heat transfer often require less energy to reach and maintain desired cooling levels.

Increased Reliability and Reduced Maintenance

Reliable operation remains a top priority for any cooling system. The Single Tube Copper Accumulator protects compressors from liquid refrigerant and ensures proper oil return. These features reduce the risk of mechanical failure. Fewer breakdowns mean less downtime and lower repair costs. Technicians also find copper accumulators easier to inspect and maintain due to their lightweight design. This reliability extends the lifespan of critical components.

Cost Savings and Versatility

Facility managers often seek solutions that balance performance with cost. The Single Tube Copper Accumulator delivers both. Its durable construction reduces the need for frequent replacements. Lower maintenance requirements translate to long-term savings. The lightweight design simplifies installation, saving labor costs. This accumulator adapts to various applications, including HVAC, refrigeration, and automotive systems. Its versatility makes it a smart investment for many industries.

Cooling systems achieve higher efficiency and reliability with this advanced accumulator. System designers, operators, and facility managers benefit from improved performance, reduced maintenance, and cost savings.

- Consider this solution for new projects or retrofits to maximize operational value and long-term success.

FAQ

What industries use the Single Tube Copper Accumulator?

HVAC, refrigeration, and automotive sectors rely on this component. It adapts to diverse systems, supporting efficient cooling and reliable operation.

How does copper improve accumulator performance?

Copper’s high thermal conductivity enables rapid heat transfer. This property increases energy efficiency and helps maintain stable temperatures throughout the cooling system.

Is the Single Tube Copper Accumulator easy to install?

Technicians find the lightweight design simplifies installation. The product’s construction allows for quick setup and easy integration into existing systems.