Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Medical Refrigeration Demand: High-Efficiency Finned Condenser for Ultra-Low Temperature

Medical refrigeration plays an essential role in healthcare and research by ensuring the safe storage of critical materials. In the U.S., the biomedical refrigerators and freezers market reached a valuation of approximately USD 1.4 billion in 2023, with a projected growth rate of 5.3% CAGR through 2032. This growth aligns with the rising demand for reliable storage solutions driven by an aging population and the increasing prevalence of chronic diseases. Ultra-low temperature solutions, valued at USD 800 million in 2023, are projected to grow significantly due to their importance in preserving vaccines, pharmaceuticals, and biological samples. A high-efficiency medical finned condenser enhances refrigeration systems by delivering precise and stable cooling, meeting the stringent requirements of modern healthcare facilities.

Key Takeaways

- Medical refrigerators are important for keeping vaccines and samples safe. Good systems stop damage and keep them working well.

- Special finned condensers make cooling better in these systems. They save energy and lower costs to run them.

- New tech like smart tools and natural coolants is changing medical refrigerators. These ideas help the environment and work better.

- Keeping the right temperature is key for delicate items. Places need to buy good refrigerators to keep things safe and steady.

- Knowing the problems with very cold temperatures helps make better designs. This helps systems work well and last longer.

Growing Demand for Medical Refrigeration

Applications in Healthcare and Research

Medical refrigeration plays a pivotal role in healthcare and research by ensuring the safe storage of temperature-sensitive materials. Hospitals and laboratories rely on specialized refrigeration units to maintain the integrity of critical substances.

- Blood bank fridges store blood and blood products under strict temperature control, preventing spoilage and ensuring their usability for transfusions.

- Explosion-proof fridges are essential for handling volatile substances in research settings, reducing fire risks by eliminating electrical components.

- Chromatography fridges provide precise temperature control for delicate lab techniques, supporting advanced research and diagnostic processes.

These applications highlight the indispensable role of refrigeration in preserving the quality and safety of medical and research materials.

Vaccine Storage and Biological Sample Preservation

The storage of vaccines and biological samples demands stringent temperature control to maintain their efficacy and usability. Vaccines, for instance, require ultra-low temperatures to prevent degradation. Biological samples, such as tissues and blood, must also be preserved under specific conditions to ensure their viability for analysis.

- Timely processing is critical to prevent the breakdown of nucleic acids and proteins in biological samples.

- Appropriate temperature control varies based on the material, ranging from refrigerated (2°C–8°C) to cryopreserved (-196°C) conditions.

- Minimal freeze-thaw cycles are necessary to protect sensitive biomolecules from damage.

These benchmarks underscore the importance of advanced refrigeration systems in maintaining the integrity of vaccines and biological specimens.

Pharmaceutical Advancements Driving Refrigeration Needs

The rapid growth of the pharmaceutical industry has significantly increased the demand for advanced medical refrigeration. Immunization programs worldwide require reliable cold storage solutions for vaccines. Blood banks have also seen a rise in refrigeration needs due to growing awareness of blood donation and the prevalence of chronic diseases.

- The biopharmaceutical industry depends on precise refrigeration for biologics and specialty drugs.

- Blood components used in transfusions require stable temperature control to ensure their safety and effectiveness.

These advancements demonstrate how innovations in pharmaceuticals continue to drive the need for cutting-edge refrigeration technologies.

Challenges in Achieving Ultra-Low Temperatures

Technical Hurdles in Maintaining Stable Ultra-Low Temperatures

Achieving and maintaining ultra-low temperatures presents significant technical challenges. Refrigeration systems must handle substantial temperature differences across various components. For instance, stainless steel shelves, often used in ultra-low temperature (ULT) freezers, require cooling due to their large mass. This adds complexity to the system's design and operation. Precise control over cooling capacity is also essential, particularly in processes like freeze-drying, where even minor temperature fluctuations can compromise product quality.

- Key technical challenges include:

- Managing significant temperature differences between components.

- Cooling large masses, such as stainless steel shelves.

- Ensuring precise cooling capacity for sensitive processes.

A deeper understanding of these hurdles has been made possible through high-resolution datasets. These datasets, spanning up to 10 years, provide insights into the performance of ULT freezers under various conditions.

| Key Features of the Dataset | Description |

|---|---|

| High-resolution historical data | Spanning up to 10 years of operational data from ULT freezers. |

| Data from various systems | Includes data from both ON/OFF and variable speed control systems. |

| Comprehensive measurements | Contains data from freezing chambers and critical locations in refrigeration systems. |

| Event labeling | Includes regular events like door operations and fault events from service reports. |

These datasets enhance the understanding of long-term performance variations and guide the development of predictive maintenance models, ensuring more reliable refrigeration systems.

Energy Efficiency and Environmental Concerns

Ultra-low temperature refrigeration systems consume significant energy, raising concerns about their environmental impact. ULT freezers account for up to 90% of their carbon footprint during use, emitting nearly 13 tonnes of CO2e annually. In comparison, an average household refrigerator emits just 0.89 tonnes of CO2e. Poor placement of ULT freezers can further increase energy consumption by 4%, highlighting the importance of proper management practices.

| Aspect | Value |

|---|---|

| Energy consumption during use | Upwards of 90% of carbon footprint |

| CO2 emissions from ULT freezers | Just under 13 tonnes of CO2e |

| CO2 emissions from average fridge | 0.89 tonnes of CO2e |

| Increase in energy consumption | 4% due to poor placement |

Replacing older ULT freezers with newer models can improve energy efficiency. However, the high cost of replacement often limits this option to cases of extreme inefficiency. Even with new systems, achieving maximum efficiency depends on effective management practices. Addressing these challenges requires innovative designs and materials that reduce energy consumption while maintaining performance.

The Need for Reliable and Precise Cooling Systems

Reliable and precise cooling systems are critical for ultra-low temperature applications. These systems ensure stable conditions, protecting sensitive materials like vaccines and biological samples from temperature fluctuations. For example, Liebherr ultra-low temperature freezers provide precision cooling for critical applications in science, medicine, and pharmaceuticals. Their design maintains stable conditions, safeguarding the efficacy of stored materials. Similarly, BINDER ultra-low freezers guarantee absolute temperature stability, ensuring proper storage for vaccines that require strict cold chain management.

The role of components like the medical finned condenser becomes crucial in achieving these outcomes. Its design enhances cooling performance, contributing to the stability and reliability of refrigeration systems. By integrating advanced technologies, these systems meet the stringent demands of modern healthcare and research facilities.

Medical Finned Condenser: A Key Component

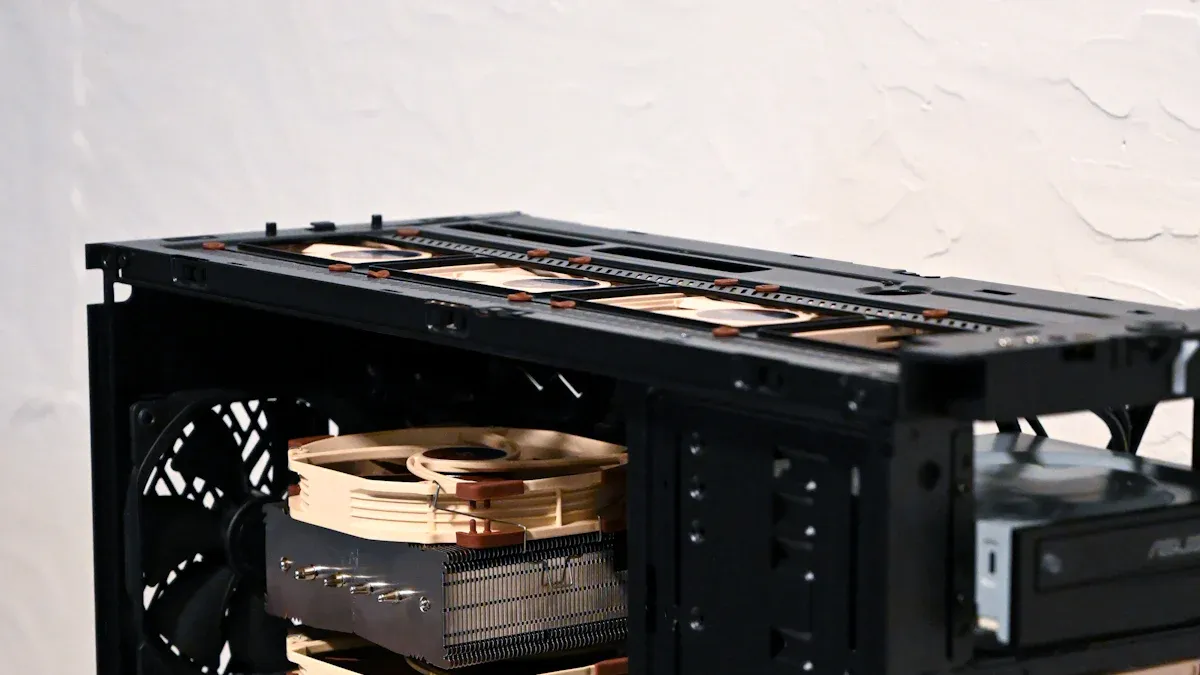

Overview of Finned Condensers and Their Function

A finned condenser is a critical component in refrigeration systems, designed to enhance heat transfer efficiency. It operates by dissipating heat from the refrigerant, allowing the system to maintain the desired low temperatures. The fins, typically made of aluminum or copper, increase the surface area for heat exchange, improving the overall cooling performance.

The functionality of a finned condenser can be better understood through its key components and their roles:

| Component/Function | Description |

|---|---|

| Steam In | Total mass flow rate of the exhaust steam, dependent on plant size and steam cycle heat rate. |

| Steam Temperature | Temperature of exhaust steam entering the condensers, estimated based on steam turbine back pressure. |

| Initial Temp. Diff. | Temperature difference between inlet steam and dry cooling system steam, affecting performance and cost. |

| Number of Cells | Number of cells in the dry cooling system, typically eight heat exchanger bundles per cell. |

| Footprint Area | Plot area of the dry cooling system, influenced by initial temperature difference and ambient pressure. |

This table highlights how each component contributes to the condenser's ability to regulate temperature effectively. By optimizing these parameters, finned condensers ensure stable and reliable cooling, which is essential for medical applications.

Design Features That Enhance Cooling Performance

The design of a medical finned condenser directly impacts its cooling efficiency. Engineers incorporate advanced features to maximize heat transfer and minimize energy consumption.

- Fin Configurations:

- Longitudinal fins increase the cooling rate and reduce solidification time.

- Pin fins improve the performance of phase-change material (PCM)-based heat sinks.

- Plate fins are commonly used in electronic cooling systems for their high efficiency.

| Fin Configuration | Impact on Cooling Performance |

|---|---|

| Longitudinal Fins | Increase cooling rate, reduce solidification time |

| Pin Fins | Improve performance of PCM-based heat sinks |

| Plate Fins | Utilized in cooling electronic equipment |

- Material Selection: Aluminum and copper are preferred for their excellent thermal conductivity and durability.

- Compact Design: Modern condensers feature compact designs to fit into smaller refrigeration units without compromising performance.

These features enable medical finned condensers to deliver precise and efficient cooling, meeting the stringent demands of ultra-low temperature systems.

Contribution to Achieving Ultra-Low Temperatures

Medical finned condensers play a pivotal role in achieving and maintaining ultra-low temperatures. Their ability to enhance heat dissipation ensures that refrigeration systems can reach target temperatures quickly and efficiently.

-

Performance Metrics:

- Ultra-low temperature cascade refrigeration systems demonstrate significant improvements with finned condensers.

- Temperature variations are effectively managed at freezing points of -40 °C, -80 °C, and -86 °C.

- Power consumption decreases from 1461.4 W to 997.5 W during the pull-down period.

- The system achieves a target temperature of -80 °C in approximately 240 minutes.

-

Case Studies:

- Finned condensers have proven essential in vaccine storage, particularly for COVID-19 vaccines. These systems maintain the ultra-low temperatures required to preserve vaccine efficacy.

By integrating advanced designs and materials, medical finned condensers ensure the reliability and precision of ultra-low temperature refrigeration systems. Their contribution is indispensable in safeguarding sensitive medical materials and supporting critical healthcare operations.

Advantages for Medical Applications

Energy Efficiency and Cost Savings

Medical refrigeration systems equipped with finned condensers offer exceptional energy efficiency. The use of louvered finsin their design significantly enhances heat exchange performance. These fins, crafted with precise dimensions and angles, maximize the cooling process while minimizing energy consumption. Internally threaded copper tubes further increase the heat exchange area, ensuring optimal efficiency. This advanced engineering reduces operational costs for healthcare facilities, making these systems a cost-effective solution for ultra-low temperature applications.

💡 Tip: Facilities can achieve long-term savings by investing in high-efficiency refrigeration systems with medical finned condensers, as they lower energy bills and reduce maintenance expenses.

Enhanced Reliability and Temperature Stability

Modern refrigeration systems with medical finned condensers deliver unparalleled reliability and temperature stability. Their design ensures consistent cooling performance, even under demanding conditions. Key performance indices validate this reliability:

| Performance Index | Description |

|---|---|

| Coefficient of Performance (COP) | Indicates the system's efficiency and stability by measuring the ratio of refrigerant effect to compressor work. |

| Refrigerant Effect | Reflects the amount of heat absorbed by the evaporator, crucial for maintaining stable temperatures. |

| Compressor Work | Represents the energy required by the compressor, directly impacting system reliability. |

These metrics highlight the ability of medical refrigeration systems to maintain precise temperature control, safeguarding sensitive materials like vaccines and biological samples.

Improved Safety for Sensitive Medical Materials

The integration of medical finned condensers enhances the safety of temperature-sensitive materials. These systems ensure consistent ultra-low temperatures, preventing degradation of critical substances. For instance, vaccines stored at improper temperatures risk losing their efficacy, which can compromise public health efforts. Similarly, biological samples require stable conditions to remain viable for research or diagnostic purposes. The advanced cooling capabilities of these systems minimize temperature fluctuations, reducing the risk of material spoilage.

By combining energy efficiency, reliability, and safety, medical finned condensers play a vital role in supporting healthcare and research operations. Their innovative design ensures that sensitive materials are preserved under optimal conditions, meeting the stringent demands of modern medical applications.

Future Innovations in Medical Refrigeration

Emerging Technologies in Refrigeration Systems

The medical refrigeration industry is undergoing a transformation driven by cutting-edge technologies. These advancements aim to improve efficiency, reduce environmental impact, and enhance reliability. Several emerging technologies are shaping the future of refrigeration systems:

- Thermoelectric Cooling: This method uses the Peltier effect to achieve efficient cooling without moving parts or chemical refrigerants.

- Magnetic Refrigeration: By leveraging the magnetocaloric effect, this innovative approach eliminates the need for traditional refrigerants, though it remains in the experimental phase.

- Natural Refrigerants: CO2, ammonia, and hydrocarbons are gaining popularity for their eco-friendly properties and reduced greenhouse gas emissions.

- IoT and AI Integration: Smart technologies enable real-time monitoring, predictive analytics, and energy optimization, ensuring precise temperature control.

- Solar-Powered Refrigeration: This solution provides reliable cooling in areas with limited access to electricity, supporting global healthcare initiatives.

These technologies reflect the industry's commitment to sustainability and efficiency, addressing the growing demand for advanced medical refrigeration solutions.

🌱 Note: The adoption of natural refrigerants and solar-powered systems aligns with global efforts to reduce carbon footprints and promote green energy.

Advancements in Finned Condenser Design and Materials

Finned condensers are evolving to meet the demands of ultra-low temperature applications. Engineers are focusing on innovative designs and materials to enhance performance and durability. Recent advancements include:

- Material Innovations: The use of eco-friendly and high-conductivity materials, such as aluminum and copper alloys, improves heat transfer efficiency while reducing environmental impact.

- Optimized Fin Configurations: Longitudinal, pin, and plate fins are being refined to maximize cooling rates and minimize energy consumption.

- Compact Designs: Modern condensers feature space-saving designs that integrate seamlessly into smaller refrigeration units without compromising functionality.

These improvements ensure that finned condensers remain a cornerstone of medical refrigeration systems, delivering reliable and energy-efficient cooling for sensitive materials.

Integration of Smart Systems for Monitoring and Control

Smart systems are revolutionizing the way refrigeration units are monitored and controlled. Advanced platforms now offer predictive analytics, real-time diagnostics, and energy management features. Key solutions include:

| Solution Name | Key Features |

|---|---|

| OpSense | IoT platform for food safety, energy management, task checklists, alerts, and reports. |

| Johnson Controls EcoStruxure™ | Predictive analytics, remote diagnostics, and live sensor data for refrigeration systems. |

| Siemens Insights Hub | Cloud-based analytics, machine learning, and predictive maintenance for critical storage. |

| Liebherr Smart Monitoring | Comprehensive monitoring, maintenance alerts, and energy efficiency optimization. |

These systems empower healthcare facilities to maintain precise temperature control, reduce energy consumption, and prevent costly equipment failures. By integrating IoT and AI technologies, medical refrigeration systems achieve unparalleled reliability and efficiency.

💡 Tip: Facilities can leverage smart monitoring solutions to streamline operations and ensure the safety of stored medical supplies.

Medical refrigeration remains a cornerstone of healthcare and research, ensuring the safe storage of vaccines, pharmaceuticals, and biological samples. Vaccines, for instance, require strict temperature control to maintain efficacy. Studies have shown that improper storage can compromise immune responses, while effective refrigeration systems significantly reduce freezing incidents. In low-income regions, where only a fraction of health facilities have refrigerators, innovative solutions are essential for maintaining the cold chain and preventing wastage.

The medical finned condenser plays a vital role in addressing these challenges. Its advanced design enhances cooling efficiency, ensuring precise temperature control for ultra-low temperature applications. This reliability safeguards sensitive materials, supporting critical healthcare operations.

Future innovations in refrigeration systems promise to further enhance performance. Emerging technologies, such as natural refrigerants and smart monitoring systems, aim to improve energy efficiency and reduce environmental impact. These advancements will continue to meet the growing demands of modern healthcare and research.

FAQ

What is the purpose of a medical finned condenser in refrigeration systems?

A medical finned condenser enhances heat dissipation in refrigeration systems. It ensures stable ultra-low temperatures by increasing the surface area for heat exchange. This component plays a critical role in preserving sensitive medical materials like vaccines and biological samples.

How do finned condensers improve energy efficiency?

Finned condensers use advanced designs, such as louvered fins and internally threaded copper tubes, to maximize heat transfer. These features reduce energy consumption by optimizing cooling performance, making refrigeration systems more cost-effective and environmentally friendly.

Why are ultra-low temperatures important in medical refrigeration?

Ultra-low temperatures prevent the degradation of sensitive materials, such as vaccines and biological samples. These conditions maintain the efficacy of stored substances, ensuring their safety and usability for healthcare and research purposes.

What materials are commonly used in finned condensers?

Finned condensers typically use aluminum or copper. These materials offer excellent thermal conductivity and durability, ensuring efficient heat transfer and long-lasting performance in refrigeration systems.

How do smart systems enhance medical refrigeration?

Smart systems provide real-time monitoring, predictive analytics, and energy optimization. These technologies ensure precise temperature control, reduce energy costs, and prevent equipment failures, making refrigeration systems more reliable for critical medical applications.