Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

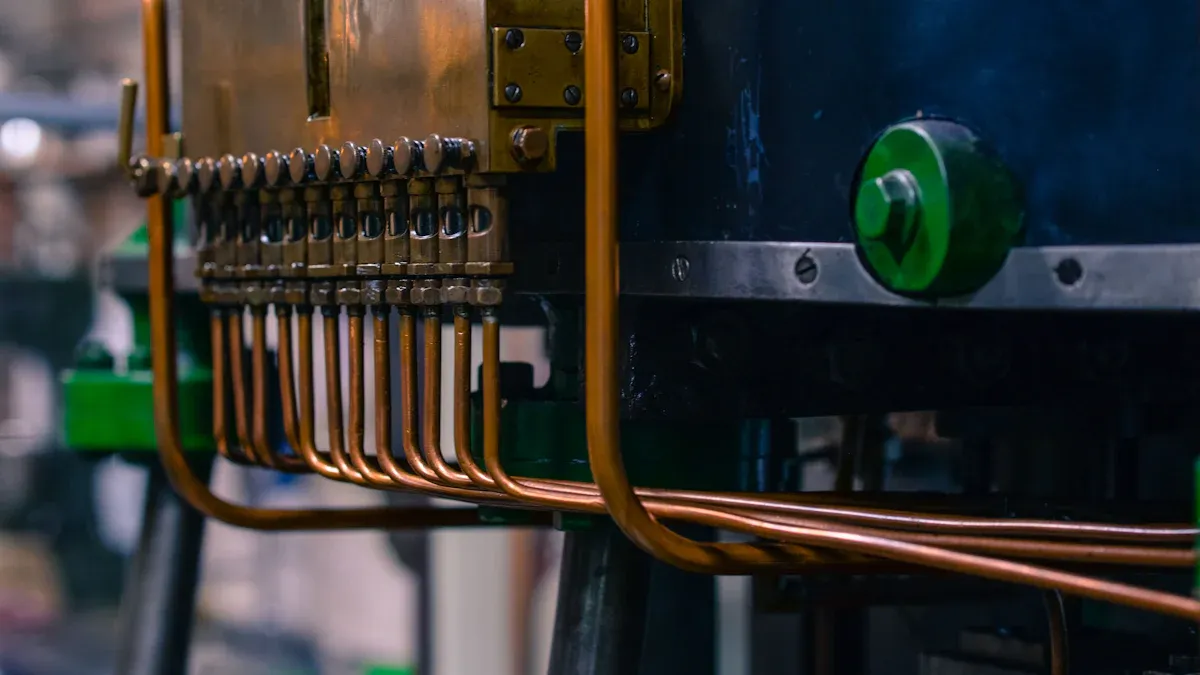

Top Refrigeration systems copper filter drier manufacturer 2025

Leading names in the refrigeration systems copper Filter Drier manufacturer sector include Ningbo Taojun, Miracle, SuperAirCool, Emerson, Danfoss, Castel S.r.l., Xiamen Trump, SHANDONG SHING CHEMICAL, Vrcooler, Parker Hannifin, Hansen Technologies, and Ningbo Kyson Cool Electronic Technology. Each company stands out for product quality, global reach, advanced technology, and strong industry reputation. Professionals seeking reliable suppliers benefit from these trusted manufacturers.

Key Takeaways

- Top refrigeration copper filter drier manufacturers deliver high-quality products that protect system components and improve efficiency.

- Certifications like ISO9001, UL, and RoHS prove a manufacturer's commitment to quality, safety, and environmental standards.

- A strong global presence and distribution network help manufacturers provide fast delivery and reliable support worldwide.

- Innovation in materials and technology leads to better moisture absorption, longer system life, and easier maintenance.

- Customer reviews highlight the importance of product reliability, affordable pricing, and excellent after-sales service.

- Choosing the right manufacturer means matching product features to your system's needs and checking for customization options.

- Technical support and quick after-sales service reduce downtime and ensure smooth system operation.

- Balancing price with product quality and service guarantees the best value and long-term performance.

Criteria for Ranking Top Refrigeration Systems Copper Filter Drier Manufacturer

Product Quality and Reliability

Manufacturers earn their reputation by delivering products that consistently perform under demanding conditions. In the refrigeration industry, copper filter driers play a vital role in protecting system components and ensuring long-term efficiency. Leading companies focus on advanced materials and engineering to meet these needs.

- Copper filter driers remove contaminants, moisture, and acids, which protects compressors and expansion valves.

- Advanced desiccants and materials improve moisture and acid absorption, supporting operational efficiency and environmental compliance.

- Danfoss filter driers, for example, use a solid core design that offers a fast adsorption rate, superior flow capacity, and low pressure drop. These features reduce maintenance costs and enhance reliability.

- Manufacturers offer various connection types, such as solder, flare, flare o-ring, and face seal, using materials like pure copper, Cu-plated, and steel for durability.

- The market emphasizes preventive maintenance and aftermarket demand, highlighting the importance of reliability and long-term system performance.

- Filter driers are tailored for specific lines, such as liquid line and suction line, to protect key components and boost overall system reliability.

A top refrigeration systems copper filter drier manufacturer prioritizes these aspects to deliver dependable solutions for diverse applications.

Industry Certifications and Standards

Certifications and adherence to industry standards set leading manufacturers apart. Companies that achieve ISO9001:2008 certification demonstrate a commitment to quality management systems. Compliance with the EU ROHS environmental protection directive and US UL certification signals dedication to safety and environmental responsibility. These certifications assure customers that products meet international benchmarks for performance, safety, and sustainability. Manufacturers that maintain rigorous testing and documentation processes build trust with clients and partners worldwide.

Global Presence and Distribution Network

A strong global presence ensures that manufacturers can serve customers efficiently across multiple regions. Leading companies invest in robust distribution networks, technical support, and inventory management to reduce lead times and improve service quality. The following table highlights key metrics that illustrate the international reach of top manufacturers:

| Metric Description | Data / Example |

|---|---|

| Global Market Share of Leading Manufacturers | Danfoss, Parker Hannifin, Emerson Electric Co. hold 45-60% combined market share |

| Regional Market Share Growth | 19% combined growth in West Coast distribution channels (Sanhua and Linquip) |

| Market Share Gains in Developing Economies | 12-15% by India’s ACRASTAR and Brazil’s Filtrak |

| Adoption Rate Improvement | 2.3X faster specification adoption in Australia due to distributor networks |

| Lead Time Reduction | 40% reduction in Europe through distributor inventory management |

| Exporting Countries | China, EU, South Korea, Japan, Taiwan, Germany, USA, Poland, India, Ukraine (top exporters) |

| Distributor Role | Geographic specialization, technical support, inventory management, faster adoption |

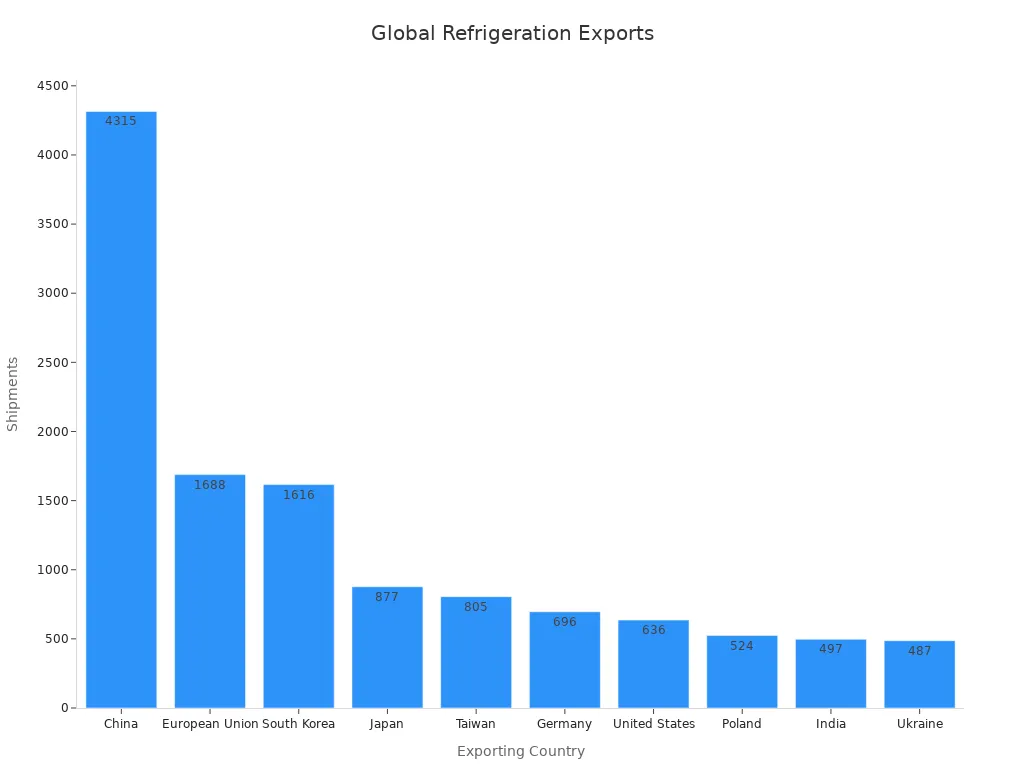

Export data further demonstrates the broad international sourcing and distribution footprint:

| Rank | Exporting Country | Export Volume (Shipments) |

|---|---|---|

| 1 | China | 4,315 |

| 2 | European Union | 1,688 |

| 3 | South Korea | 1,616 |

| 4 | Japan | 877 |

| 5 | Taiwan | 805 |

| 6 | Germany | 696 |

| 7 | United States | 636 |

| 8 | Poland | 524 |

| 9 | India | 497 |

| 10 | Ukraine | 487 |

A refrigeration systems copper filter drier manufacturer with a global footprint can respond quickly to market changes and customer needs, ensuring reliable supply and support worldwide.

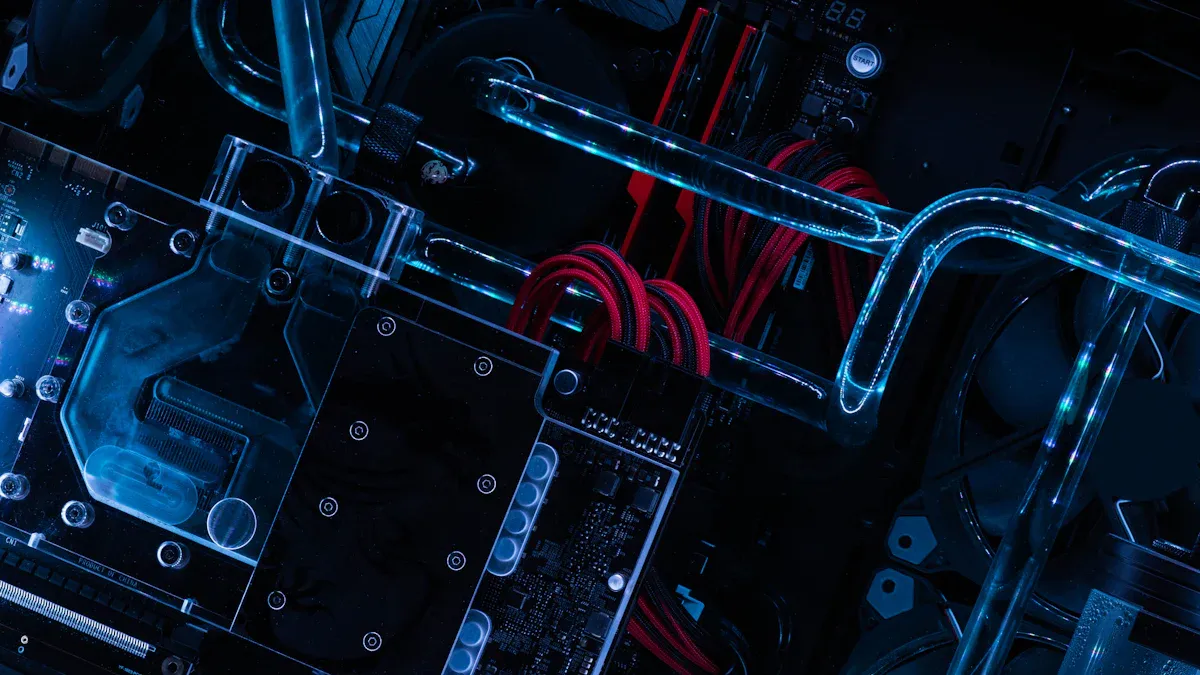

Innovation and Technological Advancements

Manufacturers in the refrigeration industry invest heavily in research and development. They introduce new materials and processes to improve the performance of copper filter driers. Many companies now use advanced desiccants that absorb moisture more efficiently. This innovation extends the lifespan of refrigeration systems and reduces maintenance needs.

Automation and precision engineering play a significant role in modern production lines. Manufacturers employ automated welding and assembly techniques. These methods ensure consistent quality and minimize human error. Some companies also utilize computer-aided design (CAD) to optimize the internal structure of filter driers. This approach enhances flow characteristics and maximizes contaminant removal.

Smart technology integration is another trend. Certain manufacturers offer filter driers with built-in sensors. These sensors monitor pressure and moisture levels in real time. Technicians can access this data remotely, which helps them schedule maintenance before problems arise.

Tip: Companies that prioritize innovation often lead the market. They set new standards for efficiency and reliability in refrigeration systems.

Continuous improvement remains a core value for every leading refrigeration systems copper filter drier manufacturer. Their commitment to technological advancement ensures that customers receive products that meet evolving industry demands.

Customer Reviews and Reputation

Customer feedback provides valuable insight into the reputation of top manufacturers. Many clients highlight fast product updates and affordable pricing. These factors indicate a strong position in a competitive market. Customers also appreciate reliable product supply and robust capital, which fosters confidence in long-term partnerships.

- Many reviews mention the principle of "Quality first, Honesty as base." This phrase reflects the trust customers place in these companies.

- Clients often state that product details meet or exceed their expectations. This supports claims of high manufacturing standards.

- The focus on scientific management and operational efficiency stands out. Customers recognize that these priorities lead to better service and product consistency.

- Competitive product quality and reasonable prices remain key reasons for choosing these manufacturers.

"The operational focus on customer priority and efficiency has fostered a long-term business relationship," one customer notes.

A refrigeration systems copper filter drier manufacturer with a strong reputation attracts repeat business and positive word-of-mouth. Their dedication to quality and customer satisfaction sets them apart in the global market.

Detailed Profiles of Top Refrigeration Systems Copper Filter Drier Manufacturer

Ningbo Taojun Refrigeration Equipment Co., Ltd.

Company Overview

Ningbo Taojun Refrigeration Equipment Co., Ltd. operates from Xiangshan, Ningbo, a city known for its scenic beauty and industrial growth. Established in 1988, the company evolved from the Xiangshan Refrigeration Accessories Factory of Zhejiang University. Over three decades, it has grown into a comprehensive enterprise that integrates design, development, production, sales, and after-sales service for refrigeration accessories. In 2021, the company achieved recognition as a national high-tech enterprise, reflecting its commitment to innovation and quality.

Key Products and Solutions

Ningbo Taojun specializes in a broad range of refrigeration system components. Its product lineup includes copper filter driers, check valves, air conditioning valves, condensers, brass and copper accessories, and air conditioning cable ties. The company also offers customized solutions to meet specific client requirements. The "Lingshan" filter drier stands out as a flagship product, widely recognized in the domestic market for its reliability and performance.

Unique Selling Points

Ningbo Taojun places strong emphasis on technological advancement and process innovation. The company invests in modern equipment and adopts advanced management concepts to ensure first-class product quality. Customer satisfaction remains a core value, supported by reasonable design, reliable quality, and comprehensive after-sales service. The "Lingshan" brand has become synonymous with trust and excellence in the Chinese refrigeration industry.

Certifications and Compliance

The company maintains strict quality control standards. It holds ISO9001:2008 quality management system certification, EU ROHS environmental protection directive certification, and US UL certification. These credentials demonstrate a commitment to international standards for safety, environmental responsibility, and product reliability.

Notable Clients and Projects

Ningbo Taojun has established long-term partnerships with leading home appliance brands such as Haier, Xinfei, Midea, Gree, Whirlpool, Electrolux, and Huarui. Its products reach customers in major Chinese cities and are exported to Europe, America, South America, Southeast Asia, the Middle East, and Africa. The company’s extensive client base and global distribution network highlight its reputation as a trusted refrigeration systems copper filter drier manufacturer.

Miracle

Company Overview

Miracle has earned a reputation as a leader in the refrigeration systems copper filter drier market. The company focuses on delivering innovative solutions that address the evolving needs of the HVAC and refrigeration industries. Miracle’s global presence and dedication to quality have positioned it as a preferred partner for manufacturers and service providers worldwide.

Key Products and Solutions

Miracle offers a comprehensive range of copper filter driers designed for both commercial and residential refrigeration systems. Its products feature advanced moisture absorption technology and efficient impurity filtration. The company also provides customized solutions to ensure compatibility with various system designs and refrigerant types.

Unique Selling Points

Miracle stands out for its commitment to energy efficiency and environmental sustainability. The company integrates cutting-edge technologies to reduce energy consumption and minimize environmental impact. Each product undergoes rigorous testing to guarantee reliability and performance. Miracle’s focus on innovation leadership and customer satisfaction has resulted in strong market acceptance and trust.

Certifications and Compliance

Miracle adheres to strict quality assurance protocols. Its products comply with international standards for safety, performance, and environmental protection. The company’s dedication to continuous improvement ensures that its offerings remain at the forefront of the industry.

Notable Clients and Projects

Manufacturers and service providers across the globe rely on Miracle’s copper filter driers. The company’s solutions support a wide range of applications, from large-scale commercial refrigeration systems to specialized industrial projects. High customer satisfaction and repeat business underscore Miracle’s status as a top refrigeration systems copper filter drier manufacturer.

SuperAirCool

Company Overview

SuperAirCool has established itself as a prominent player in the global refrigeration systems market. The company focuses on engineering high-performance copper filter driers that meet the demands of modern refrigeration and air conditioning systems. Its commitment to quality and innovation drives its success in both domestic and international markets.

Key Products and Solutions

SuperAirCool manufactures copper filter driers capable of withstanding high pressures up to 100 pounds. The use of premium copper ensures superior durability, corrosion resistance, and excellent thermal conductivity. The desiccant material inside each filter drier effectively removes moisture, preventing ice formation, corrosion, and acid buildup. The company offers a variety of sizes and capacities to accommodate different system requirements.

Unique Selling Points

- SuperAirCool’s filter driers undergo rigorous quality and performance testing.

- The design ensures low pressure drop, maintaining efficient refrigerant flow.

- Products are compatible with eco-friendly refrigerants, supporting sustainability.

- The recyclability of copper enhances the environmental profile of the product.

- Proper installation and regular maintenance contribute to long-term durability and optimal performance.

SuperAirCool’s focus on increased system efficiency, longer equipment lifespan, and reduced maintenance costs has driven its global market success.

Certifications and Compliance

SuperAirCool meets stringent industry standards through comprehensive testing and quality assurance processes. The company’s products align with international safety and environmental regulations, ensuring reliability and peace of mind for customers.

Notable Clients and Projects

SuperAirCool serves a diverse client base, including commercial refrigeration contractors, OEMs, and service providers. Its products are widely used in projects that demand high reliability and efficiency. The company’s global reach and consistent product quality have made it a preferred choice in the refrigeration systems copper filter drier manufacturer sector.

Emerson (Emerson Climate Technologies)

Company Overview

Emerson Climate Technologies operates as a global leader in the HVAC and refrigeration industry. The company forms part of Emerson Electric Co., a corporation with a long-standing reputation for engineering excellence. Emerson Climate Technologies focuses on delivering advanced solutions for temperature control, energy efficiency, and system reliability. The company maintains a strong presence in North America, Europe, Asia, and other key markets.

Key Products and Solutions

Emerson offers a comprehensive range of copper filter driers designed for both commercial and residential refrigeration systems. The product lineup includes liquid line filter driers, suction line filter driers, and bi-flow filter driers. Emerson's filter driers feature high-quality copper construction, advanced desiccant blends, and optimized flow paths. These products help remove moisture, acids, and contaminants, ensuring the longevity and efficiency of refrigeration systems. Emerson also provides compatible accessories and replacement parts to support a wide variety of system configurations.

Unique Selling Points

Emerson distinguishes itself through a commitment to innovation and quality. The company invests heavily in research and development, introducing new materials and manufacturing processes that enhance product performance. Emerson leverages advanced manufacturing technologies to maintain consistent quality across its product range. Strategic collaborations and acquisitions allow Emerson to expand its portfolio and reach new markets. The company’s extensive distribution network ensures timely delivery and technical support for customers worldwide.

Emerson’s focus on technological advancement and market expansion has solidified its leadership in the refrigeration systems copper filter drier manufacturer sector.

Certifications and Compliance

Emerson Climate Technologies adheres to strict international standards. The company’s filter driers meet ISO 9001 quality management requirements and comply with major safety and environmental regulations, including UL and RoHS. Emerson’s rigorous testing protocols guarantee product reliability and safety for end users.

Notable Clients and Projects

Emerson serves a diverse client base, including major OEMs, commercial contractors, and service providers. Its products appear in large-scale supermarket refrigeration systems, industrial cold storage facilities, and residential HVAC units. Emerson’s reputation for reliability and innovation has led to long-term partnerships with leading brands in the refrigeration and air conditioning industry.

Danfoss

Company Overview

Danfoss stands as a prominent multinational engineering company specializing in refrigeration, air conditioning, and heating solutions. Founded in Denmark, Danfoss has expanded its operations to serve customers in over 100 countries. The company’s focus on sustainable technology and energy efficiency drives its product development and market strategy.

Key Products and Solutions

Danfoss manufactures a wide array of copper filter driers for refrigeration and air conditioning applications. The product range includes solid core filter driers, replaceable core driers, and bi-flow models. Danfoss designs its filter driers to provide rapid moisture and acid absorption, low pressure drop, and high dirt retention. The company also offers specialized filter driers for use with environmentally friendly refrigerants and high-pressure systems.

Unique Selling Points

Danfoss emphasizes product reliability, energy efficiency, and environmental responsibility. The company uses advanced desiccant materials and precision engineering to ensure optimal performance. Danfoss filter driers support both traditional and modern refrigerants, making them suitable for a wide range of applications. The company’s global research centers drive continuous innovation, keeping Danfoss at the forefront of the refrigeration systems copper filter drier manufacturer market.

Danfoss’s dedication to sustainability and technical excellence has earned it a strong reputation among industry professionals.

Certifications and Compliance

Danfoss maintains compliance with international quality and safety standards. The company’s filter driers carry ISO 9001 certification and meet UL, CE, and RoHS requirements. Danfoss implements strict quality control measures throughout its manufacturing process to ensure consistent product performance.

Notable Clients and Projects

Danfoss supplies filter driers to leading refrigeration and HVAC manufacturers, supermarket chains, and industrial facilities. Its products feature in high-profile projects, including commercial refrigeration installations, food processing plants, and energy-efficient building systems. Danfoss’s global reach and trusted brand make it a preferred partner for demanding applications.

Castel S.r.l.

Company Overview

Castel S.r.l. is an Italian company with a rich history in the refrigeration and air conditioning industry. Established in Milan, Castel has built a reputation for quality craftsmanship and technical expertise. The company focuses on designing and manufacturing components for refrigeration systems, with a strong emphasis on copper filter driers.

Key Products and Solutions

Castel produces a broad selection of copper filter driers, including liquid line, suction line, and bi-flow models. The company’s filter driers feature robust copper bodies, high-performance desiccants, and precision-engineered internal structures. Castel also offers a variety of connection types and sizes to accommodate different system requirements. The product range extends to other refrigeration components, such as solenoid valves and sight glasses.

Unique Selling Points

Castel combines traditional Italian manufacturing techniques with modern technology. The company prioritizes product durability, ease of installation, and compatibility with a wide range of refrigerants. Castel’s filter driers undergo thorough quality testing to ensure reliability in demanding environments. The company’s flexibility in customization allows it to meet specific customer needs.

Castel’s blend of heritage, innovation, and customer focus has established it as a respected refrigeration systems copper filter drier manufacturer in Europe and beyond.

Certifications and Compliance

Castel adheres to international standards for quality and safety. The company’s products hold ISO 9001 certification and comply with CE and PED directives. Castel’s commitment to regulatory compliance ensures safe and reliable operation in diverse markets.

Notable Clients and Projects

Castel supplies components to OEMs, refrigeration contractors, and distributors across Europe, Asia, and the Americas. Its filter driers appear in commercial refrigeration systems, cold storage warehouses, and specialized industrial applications. Castel’s reputation for quality and service has led to long-standing relationships with major industry players.

Xiamen Trump Refrigeration Parts Co., Ltd.

Company Overview

Xiamen Trump Refrigeration Parts Co., Ltd. operates from Xiamen, China. The company has built a strong reputation in the HVAC and refrigeration industry. Since its founding, Xiamen Trump has focused on the research, development, and manufacturing of high-quality refrigeration components. The company serves both domestic and international markets, offering reliable solutions for a wide range of applications.

Key Products and Solutions

Xiamen Trump manufactures a comprehensive selection of copper filter driers. The product line includes liquid line filter driers, suction line filter driers, and bi-flow filter driers. The company also produces other refrigeration accessories such as sight glasses, accumulators, and valves. Each product features robust copper construction and advanced desiccant materials. These features help ensure effective moisture and acid removal from refrigeration systems.

Unique Selling Points

- Xiamen Trump emphasizes product customization. The company tailors filter driers to meet specific customer requirements.

- The engineering team uses advanced production techniques to maintain consistent quality.

- Fast delivery and responsive customer service set Xiamen Trump apart from many competitors.

- The company invests in continuous improvement, updating its product designs to match evolving industry standards.

Customers often praise Xiamen Trump for its flexibility and willingness to develop custom solutions for unique system needs.

Certifications and Compliance

Xiamen Trump holds several important certifications. The company has achieved ISO 9001 certification for quality management. Its products comply with RoHS and CE directives, ensuring safety and environmental responsibility. These certifications demonstrate the company’s commitment to meeting international standards.

Notable Clients and Projects

Xiamen Trump supplies products to a diverse client base. The company works with OEMs, refrigeration contractors, and distributors in Asia, Europe, and the Americas. Its filter driers appear in commercial refrigeration systems, cold storage facilities, and air conditioning units. Many clients choose Xiamen Trump as their preferred refrigeration systems copper filter drier manufacturer due to its reliability and service.

SHANDONG SHING CHEMICAL CO., LTD.

Company Overview

SHANDONG SHING CHEMICAL CO., LTD. operates as a leading manufacturer in the refrigeration and chemical industries. The company is based in Shandong Province, China. Over the years, SHING CHEMICAL has expanded its product offerings and built a strong presence in both domestic and global markets.

Key Products and Solutions

SHING CHEMICAL specializes in copper filter driers for refrigeration systems. The company also produces refrigerants, desiccants, and other chemical additives. Its filter driers use high-purity copper and advanced desiccant blends. These products help protect compressors and other system components from moisture and contaminants.

Unique Selling Points

- SHING CHEMICAL integrates chemical expertise into its filter drier design, resulting in superior moisture absorption.

- The company offers a wide range of filter drier sizes and configurations.

- Strong research and development capabilities allow SHING CHEMICAL to introduce new products quickly.

- The company maintains competitive pricing without sacrificing quality.

SHING CHEMICAL’s focus on innovation and chemical engineering gives it an edge in the refrigeration systems market.

Certifications and Compliance

SHING CHEMICAL holds ISO 9001 certification for quality management. The company’s products meet RoHS and CE standards. Regular audits and testing ensure ongoing compliance with international regulations.

Notable Clients and Projects

SHING CHEMICAL supplies filter driers and refrigerants to major appliance manufacturers, HVAC contractors, and distributors worldwide. Its products are used in supermarket refrigeration, industrial cooling, and residential air conditioning. The company’s reputation as a reliable refrigeration systems copper filter drier manufacturer continues to grow in global markets.

Vrcooler

Company Overview

Vrcooler operates as a dynamic supplier in the refrigeration and HVAC industry. The company is headquartered in China and serves customers around the world. Vrcooler focuses on providing high-quality components and technical support for refrigeration systems.

Key Products and Solutions

Vrcooler offers a broad portfolio of copper filter driers. The product range includes standard and custom filter driers for liquid and suction lines. Vrcooler also supplies related components such as expansion valves, sight glasses, and pressure controls. The company’s filter driers use premium copper and high-efficiency desiccants to ensure optimal system protection.

Unique Selling Points

- Vrcooler provides fast shipping and flexible order quantities, making it suitable for both large and small projects.

- The company offers technical support and guidance to help clients select the right filter drier for their application.

- Vrcooler’s products are compatible with a wide variety of refrigerants, including environmentally friendly options.

- The company maintains a strong focus on customer satisfaction and after-sales service.

Many customers value Vrcooler’s responsive service and ability to deliver reliable products on short notice.

Certifications and Compliance

Vrcooler’s manufacturing processes meet ISO 9001 quality standards. The company’s products comply with CE and RoHS directives. These certifications ensure that Vrcooler’s filter driers meet international safety and environmental requirements.

Notable Clients and Projects

Vrcooler supplies filter driers to refrigeration contractors, OEMs, and distributors in Europe, North America, and Asia. Its products are used in commercial refrigeration, industrial cooling, and residential HVAC systems. Vrcooler’s reputation as a trusted refrigeration systems copper filter drier manufacturer continues to strengthen as it expands its global reach.

Parker Hannifin

Company Overview

Parker Hannifin stands as a global leader in motion and control technologies. The company began operations in 1917 and has since expanded its reach to over 50 countries. Parker Hannifin focuses on engineering solutions for a wide range of industries, including refrigeration, aerospace, and industrial manufacturing. The company’s strong commitment to innovation and quality has earned it a trusted reputation among professionals worldwide.

Key Products and Solutions

Parker Hannifin offers an extensive portfolio of copper filter driers for refrigeration systems. The product range includes liquid line filter driers, suction line filter driers, and bi-flow models. Each filter drier features high-grade copper construction and advanced desiccant blends. These products remove moisture, acids, and contaminants from refrigeration circuits. Parker Hannifin also provides accessories such as sight glasses, valves, and pressure controls to support complete system integration.

Unique Selling Points

- Parker Hannifin invests heavily in research and development. The company introduces new materials and designs that improve system efficiency.

- The company’s filter driers support a wide range of refrigerants, including environmentally friendly options.

- Parker Hannifin maintains a global distribution network. Customers receive fast delivery and technical support in every major market.

- The company’s focus on reliability and performance ensures long service life for refrigeration equipment.

Note: Parker Hannifin’s dedication to customer satisfaction and continuous improvement sets it apart as a top choice for system designers and contractors.

Certifications and Compliance

Parker Hannifin adheres to strict international standards. The company’s filter driers carry ISO 9001 certification and comply with UL, CE, and RoHS directives. Regular audits and quality checks ensure that every product meets safety and environmental requirements.

Notable Clients and Projects

Parker Hannifin supplies components to leading OEMs, refrigeration contractors, and distributors worldwide. Its filter driers appear in supermarket refrigeration, industrial cooling plants, and commercial HVAC systems. The company’s reputation as a reliable refrigeration systems copper filter drier manufacturer continues to grow through successful partnerships and high-profile projects.

Hansen Technologies

Company Overview

Hansen Technologies operates as a specialist in industrial refrigeration controls and components. The company started in the United States and has expanded its presence to serve customers globally. Hansen Technologies focuses on providing innovative solutions for ammonia and halocarbon refrigeration systems. The company’s expertise covers both standard and custom-engineered products.

Key Products and Solutions

Hansen Technologies manufactures a range of copper filter driers designed for demanding industrial applications. The product lineup includes liquid line and suction line filter driers, as well as replaceable core models. Hansen Technologies also produces valves, pressure regulators, and safety devices. Each filter drier uses high-quality copper and advanced desiccant materials to ensure effective moisture and contaminant removal.

Unique Selling Points

- Hansen Technologies specializes in solutions for large-scale and industrial refrigeration systems.

- The company’s engineering team develops products that withstand harsh operating conditions.

- Hansen Technologies offers technical support and training for system installers and operators.

- The company’s products integrate easily with other system components, supporting efficient maintenance and upgrades.

Tip: Hansen Technologies’ focus on industrial applications makes it a preferred partner for food processing, cold storage, and chemical manufacturing facilities.

Certifications and Compliance

Hansen Technologies maintains ISO 9001 certification for quality management. The company’s products comply with major international safety and environmental standards, including UL and CE. Regular product testing and documentation ensure ongoing compliance.

Notable Clients and Projects

Hansen Technologies supplies filter driers and controls to industrial refrigeration contractors, OEMs, and facility managers. Its products appear in food processing plants, cold storage warehouses, and large-scale distribution centers. The company’s reputation for reliability and technical expertise has led to long-term relationships with industry leaders.

Ningbo Kyson Cool Electronic Technology Co., Ltd.

Company Overview

Ningbo Kyson Cool Electronic Technology Co., Ltd. operates from Ningbo, China. The company specializes in the design and production of refrigeration system components. Since its founding, Ningbo Kyson Cool has focused on delivering high-quality products for both domestic and international markets. The company’s commitment to innovation and customer service drives its growth.

Key Products and Solutions

Ningbo Kyson Cool manufactures a variety of copper filter driers for refrigeration and air conditioning systems. The product range includes liquid line, suction line, and bi-flow filter driers. Each unit features robust copper construction and high-efficiency desiccants. The company also offers related products such as valves, accumulators, and sight glasses to support complete system solutions.

Unique Selling Points

- Ningbo Kyson Cool emphasizes product customization. The company tailors filter driers to meet specific customer requirements.

- The company uses advanced manufacturing techniques to ensure consistent quality.

- Fast order processing and responsive customer support distinguish Ningbo Kyson Cool in the market.

- The company’s products support a wide range of refrigerants and system configurations.

Many customers appreciate Ningbo Kyson Cool’s flexibility and willingness to develop solutions for unique project needs.

Certifications and Compliance

Ningbo Kyson Cool holds ISO 9001 certification for quality management. The company’s products comply with CE and RoHS directives. Regular quality audits and testing ensure that every filter drier meets international standards for safety and performance.

Notable Clients and Projects

Ningbo Kyson Cool supplies filter driers to OEMs, refrigeration contractors, and distributors in Asia, Europe, and the Americas. Its products appear in commercial refrigeration systems, residential air conditioning units, and specialized industrial applications. The company’s reputation as a trusted refrigeration systems copper filter drier manufacturer continues to expand with each successful project.

How to Choose the Right Refrigeration Systems Copper Filter Drier Manufacturer

Assessing Application Requirements

Selecting the right refrigeration systems copper filter drier manufacturer begins with a clear understanding of the application. Each refrigeration system has unique demands based on capacity, refrigerant type, and environmental conditions. Engineers should identify whether the system operates in a commercial, industrial, or residential setting. They must also consider the type of refrigerant, system pressure, and required moisture removal efficiency. For example, high-capacity supermarket refrigeration systems need filter driers with greater contaminant holding capacity and robust construction. In contrast, residential units may require compact designs with standard filtration. Matching the filter drier’s specifications to the system’s needs ensures optimal performance and longevity.

Tip: Always review the manufacturer’s technical datasheets to confirm compatibility with your system’s refrigerant and operating conditions.

Evaluating Product Range and Customization

A comprehensive product range and customization options set leading manufacturers apart. Some companies, like Dry All, offer an extensive selection of liquid and suction line filter driers, including bead type and solid core configurations. They provide advanced customization, such as Schrader valve integration, moisture indicators, and diverse connection types. These features allow system designers to optimize performance and maintenance efficiency.

The following table compares product range and customization options among manufacturers:

| Feature / Manufacturer | Dry All (HVAC&R Filter Driers) | Chinese Shell Type Refrigerant Filter Drier Manufacturer |

|---|---|---|

| Product Range | Extensive, multiple configurations | Shell type, various sizes |

| Customization Options | Advanced, including tailor-made solutions | Focus on robustness, limited customization |

| Innovation Focus | High, unique solutions | Durability and filtration efficiency |

| Maintenance | Easy servicing, Schrader valves | Replaceable filter elements |

| Targeted Benefits | Optimized design and maintenance | Long service life, reliability |

Manufacturers focusing on robustness, such as those producing shell type filter driers, emphasize copper or steel shells, corrosion resistance, and easy maintenance. These features benefit users seeking durability and reduced maintenance frequency. When evaluating a refrigeration systems copper filter drier manufacturer, buyers should prioritize those offering both a broad product range and the ability to tailor solutions for specific system requirements.

Considering Order Volume and Lead Times

Order volume and lead times play a crucial role in supplier selection. Manufacturers often provide different lead times based on the quantity ordered. For instance, a typical lead time for orders between 1 and 200 pieces is 20 days. Larger orders require negotiation to determine delivery schedules.

| Order Quantity (pieces) | Lead Time (days) |

|---|---|

| 1 to 200 | 20 |

| More than 200 | Negotiable |

Buyers should assess their project timelines and inventory needs before placing orders. Reliable manufacturers communicate lead times clearly and offer flexibility for bulk orders. Fast and predictable delivery supports uninterrupted project schedules and helps maintain system uptime.

Note: Establishing a strong relationship with a manufacturer can lead to better terms and faster response times for urgent orders.

Reviewing Technical Support and After-Sales Service

Technical support and after-sales service play a crucial role when selecting a refrigeration systems copper filter drier manufacturer. Customers often need guidance during installation, troubleshooting, or maintenance. Manufacturers that provide responsive support help reduce downtime and prevent costly errors.

A top manufacturer offers several support channels. These may include phone hotlines, email assistance, live chat, and online resources. Many companies also provide detailed product manuals and video tutorials. Some even assign dedicated account managers for large clients. This approach ensures that customers receive prompt and accurate answers to their questions.

Tip: Always check if the manufacturer offers 24/7 technical support, especially for critical applications.

After-sales service extends beyond initial installation. Leading manufacturers handle warranty claims efficiently. They supply replacement parts quickly and offer on-site assistance when needed. Some companies conduct regular follow-ups to ensure customer satisfaction. This proactive approach builds trust and encourages long-term partnerships.

Customers should review testimonials and case studies. These resources reveal how the manufacturer responds to real-world issues. A strong reputation for technical support often signals a reliable partner.

Comparing Pricing and Value

Pricing remains a key factor in the decision-making process. However, buyers should look beyond the initial cost. Value includes product quality, durability, and the level of service provided. A refrigeration systems copper filter drier manufacturer that offers competitive pricing and high value stands out in the market.

The following table highlights important aspects to consider when comparing manufacturers:

| Factor | What to Look For |

|---|---|

| Product Price | Transparent and competitive rates |

| Quality Assurance | Consistent performance and reliability |

| Warranty Coverage | Clear terms and responsive claims process |

| Service Inclusions | Technical support and after-sales care |

| Delivery Terms | Fast shipping and flexible logistics |

Some manufacturers may offer lower prices but compromise on quality or support. Others provide premium products with extended warranties and comprehensive service packages. Buyers should calculate the total cost of ownership, including maintenance and potential downtime.

Note: The best value often comes from a balanced approach—reasonable pricing, strong support, and proven reliability.

By carefully reviewing both pricing and value, customers can select a manufacturer that meets their budget and performance expectations.

Frequently Asked Questions About Refrigeration Systems Copper Filter Drier Manufacturer

What is a copper filter drier and why is it important?

A copper filter drier is a critical component in refrigeration systems. It removes moisture and particulates from the refrigerant, ensuring the system operates efficiently and reliably. Technicians typically install copper filter driers in the liquid line near the metering device, with the preferred orientation being vertical and flow directed downward. This placement helps maximize the removal of contaminants before they reach sensitive components.

Copper filter driers serve as cost-effective solutions, especially in fractional-horsepower and low-vibration refrigeration systems. They use a desiccant bed to absorb moisture and trap debris, which protects compressors and expansion valves from damage. When used with capillary tubes, the outlet design allows for easy brazing without restricting refrigerant flow. For larger or higher-flow systems, manufacturers may include a spring-loaded desiccant bed to prevent desiccant attrition.

The significance of copper filter driers lies in their ability to:

- Prevent ice formation and corrosion by removing moisture.

- Trap dirt, acids, and other contaminants.

- Extend the lifespan of compressors and other components.

- Support energy efficiency and optimal cooling performance.

Proper installation and regular replacement of copper filter driers help maintain system reliability and reduce maintenance costs.

How do I know if a manufacturer is reliable?

A reliable refrigeration systems copper filter drier manufacturer demonstrates several key indicators. Customers should look for the following qualities:

- Proven Moisture Removal: The manufacturer’s products effectively eliminate moisture, preventing ice and corrosion.

- Superior Contaminant Filtration: Their filter driers trap dirt, debris, and acids, protecting system components.

- Acid Neutralization: The driers neutralize acids formed within the system, reducing the risk of corrosion.

- Extended Compressor Life: By removing harmful elements, the filter driers help prolong compressor lifespan and reduce maintenance needs.

- Consistent Cooling Performance: Reliable manufacturers deliver products that maintain efficient temperature control.

- System Damage Prevention: Their filter driers act as barriers against corrosion, ice, and component failure.

- Energy Efficiency: The products support optimal system conditions, lowering energy consumption.

Manufacturers like Miracle, with over 20 years of experience and partnerships with major brands such as LG, Samsung, and Whirlpool, exemplify reliability. They maintain strict quality control, provide detailed product specifications, and offer customization services. Verified Market Reports highlight that trusted manufacturers drive market growth through technological advancements and regulatory compliance.

What certifications should I look for?

Certifications play a vital role in verifying the quality and safety of copper filter driers. When evaluating a manufacturer, customers should check for the following certifications:

| Certification | Purpose | Common Issuers |

|---|---|---|

| ISO9001 | Quality management system | International Org. |

| ISO14001 | Environmental management system | International Org. |

| UL | Product safety and compliance | Underwriters Labs |

| EU ROHS | Restriction of hazardous substances | European Union |

| CE | Conformity with European safety standards | European Union |

Manufacturers holding these certifications, such as Miracle and others listed in Verified Market Reports, demonstrate a commitment to product quality, environmental responsibility, and international safety standards. These credentials assure customers that the manufacturer’s products meet rigorous industry requirements and can be trusted for use in diverse applications.

Always request documentation of certifications before making a purchasing decision.

Can I request custom filter drier solutions?

Many refrigeration systems require filter driers tailored to unique operational needs. Leading manufacturers recognize this demand and offer custom solutions to meet specific requirements. Clients often request modifications in size, connection type, desiccant blend, or pressure rating. Manufacturers like Ningbo Taojun, Miracle, and Danfoss provide engineering teams that collaborate with customers to design filter driers optimized for their systems.

Custom filter drier solutions benefit industries with non-standard refrigerants, high-capacity systems, or challenging environmental conditions. For example, a food processing facility may need a filter drier with enhanced acid absorption, while a commercial HVAC contractor might require a compact design for limited installation space.

Tip: When requesting a custom solution, clients should prepare detailed system specifications, including refrigerant type, flow rate, operating pressure, and installation constraints. This information helps manufacturers recommend the best materials and configurations.

The process for obtaining a custom filter drier typically involves:

- Submitting technical requirements and system details.

- Reviewing design proposals and material options.

- Approving prototypes or samples for testing.

- Finalizing production and delivery schedules.

Manufacturers with strong R&D capabilities can also provide rapid prototyping and small-batch production for pilot projects. Many companies offer ongoing technical support to ensure the custom filter drier performs as intended throughout its service life.

How do I maintain and replace copper filter driers?

Proper maintenance and timely replacement of copper filter driers ensure optimal performance and protect refrigeration systems from costly failures. Technicians should follow a structured approach to maximize equipment lifespan and system reliability.

- Regular installation and replacement of copper filter driers prevent compressor damage caused by particulates.

- The frequency of filter drier changes depends on refrigerant type and job duration. For larger or more demanding jobs, changing the filter drier more often than the minimum recommendation provides added protection.

- Cleaning or replacing inlet mesh filter screens helps prevent clogging and maintains efficient refrigerant flow.

- After recovering refrigerant, purging the recovery machine avoids cross-contamination between different refrigerants.

- Performance indicators that signal the need for maintenance or replacement include:

- Slow refrigerant recovery

- Excessive compressor noise

- Inability to hold pressure

- Unusual knocking sounds

Routine maintenance tasks also include cleaning the machine after each use, protecting inlet and discharge ports from debris, and running oil through the system to scavenge contaminants. Proper storage, such as keeping valves open and ensuring no excess refrigerant remains, prevents pressure buildup and extends equipment life.

Neglecting maintenance can lead to irreversible damage, making repair impossible and requiring full replacement of the filter drier or even the entire recovery machine.

With diligent care, copper filter driers and associated equipment can last 10 to 20 years. Technicians who follow best practices not only extend the lifespan of their systems but also ensure safe and efficient operation for every application.

Industry leaders such as Ningbo Taojun, Miracle, and Danfoss set high standards for quality and innovation in this field. Each refrigeration systems copper filter drier manufacturer offers unique strengths that suit different project requirements. Readers should review the detailed profiles and ranking criteria to select the best partner for their application. Careful evaluation ensures reliable system performance and long-term value.

FAQ

What materials do top manufacturers use for copper filter driers?

Leading manufacturers use high-purity copper for the shell and advanced desiccants inside. This combination ensures durability, corrosion resistance, and effective moisture removal. The choice of materials supports long service life and reliable system performance.

How often should technicians replace copper filter driers?

Technicians should replace copper filter driers during major repairs, after compressor failures, or when moisture contamination occurs. Regular maintenance schedules recommend replacement every 1–2 years for optimal system protection.

Can copper filter driers work with all refrigerants?

Most copper filter driers support a wide range of refrigerants, including traditional and eco-friendly options. Always check the manufacturer’s specifications to confirm compatibility with specific refrigerant types.

Why do certifications matter when choosing a manufacturer?

Certifications such as ISO9001, UL, and RoHS demonstrate a manufacturer’s commitment to quality, safety, and environmental standards. These credentials assure buyers that products meet international requirements and perform reliably.

What technical support do top manufacturers provide?

Top manufacturers offer technical documentation, installation guides, and responsive customer service. Many provide online resources, troubleshooting assistance, and direct support for complex projects.

How do manufacturers ensure product quality?

Manufacturers implement strict quality control processes, including material inspections, automated testing, and batch traceability. Regular audits and compliance checks maintain consistent product standards.

Are custom filter drier solutions available for unique applications?

Yes, many manufacturers design custom filter driers to meet specific system requirements. Clients can request modifications in size, connection type, or desiccant blend for specialized applications.

What are the signs of a failing copper filter drier?

Common signs include reduced cooling efficiency, unusual system noises, and visible moisture or debris in the sight glass. Prompt replacement prevents further system damage.