Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Top Strategies for Efficient Welding Torch Usage

Efficient welding torch usage plays a pivotal role in improving productivity while minimizing operational costs. In manual welding, operators often achieve an arc-on time of just 10 to 12%, with a maximum of 20%. This limited duration translates to approximately 60 minutes of active welding in a 10-hour workday. Optimizing welding processes can significantly enhance productivity by increasing arc-on time, reducing material waste, and lowering labor costs associated with cleanup and repairs.

Advanced tools like Taojun HVAC’s Welding Torch Tools for Refrigeration Systems offer precision and reliability, helping professionals achieve these goals. With features such as high-temperature flames exceeding 2000°C and ergonomic designs, these tools streamline welding tasks and ensure consistent results across various applications.

Key Takeaways

- Use welding torches wisely to save time and money. Keep the arc on longer to waste less material.

- Pick the right torch for the gas and heat needed. This helps join metals like copper and aluminum better.

- Check and clean your welding torch often to keep it working well. Clean the nozzle and look for broken parts to avoid problems.

- Choose comfy and strong tools to work safely and easily. Good tools last longer and help you work faster.

- Always follow safety rules, like wearing gear and keeping oil away from oxygen tanks. This keeps the workspace safe.

Selecting the Right Welding Torch

Factors to Consider for Refrigeration Systems

Choosing the right welding torch for refrigeration systems requires careful evaluation of gas type, flame temperature, and application compatibility. Refrigeration tasks often involve joining copper, brass, or aluminum components, which demand precise heat control and flame stability. Taojun HVAC’s Welding Torch Tools for Refrigeration Systems excel in these applications due to their high-temperature capabilities and versatile gas compatibility.

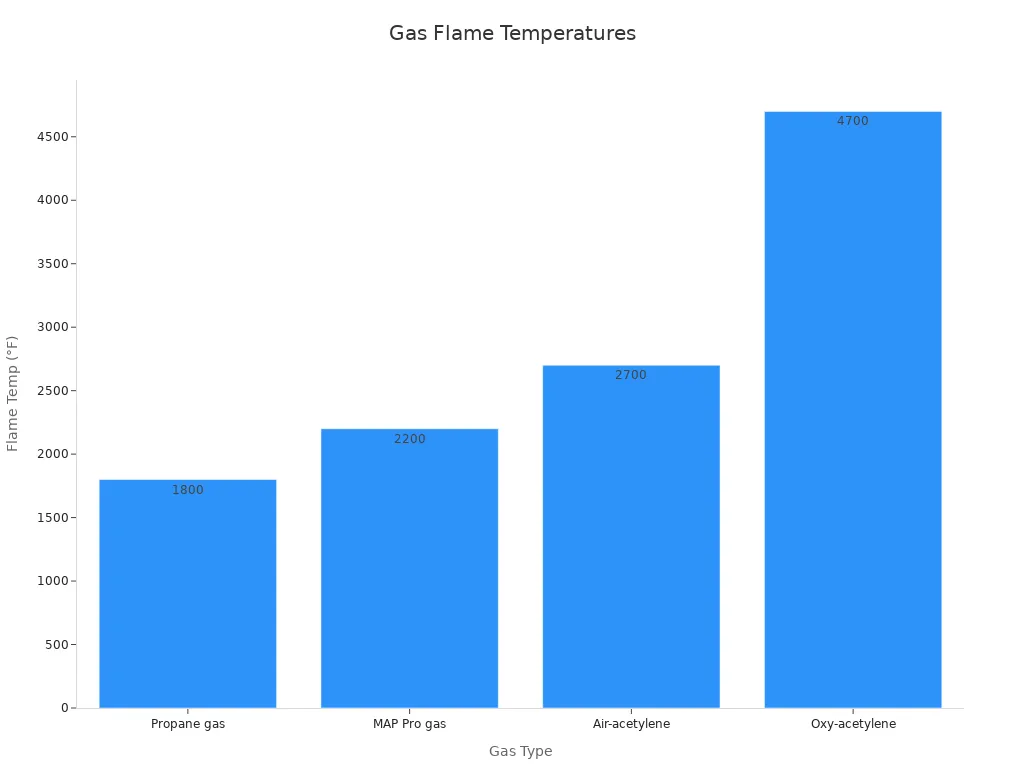

The table below highlights key gas types and their corresponding flame temperatures, helping professionals select the most suitable option for their specific needs:

| Gas Type | Flame Temperature (°F) | Applications |

|---|---|---|

| Propane gas | 1800 | Aluminum-to-aluminum and aluminum-to-copper joints |

| MAP Pro gas | 2200 | Aluminum-to-aluminum and aluminum-to-copper joints |

| Air-acetylene | 2700 | Copper-to-copper, copper-to-brass, copper-to-steel joints |

| Oxy-acetylene | 4700 | Copper-to-copper, copper-to-brass, copper-to-steel joints |

Professionals working with copper-to-copper or copper-to-brass joints often prefer air-acetylene or oxy-acetylene due to their higher flame temperatures. Taojun HVAC’s torches are compatible with MAPP and propane gases, ensuring flexibility across various refrigeration applications.

Comparing Models: LV-2B vs. LV-A

Taojun HVAC offers two exceptional welding torch models tailored for refrigeration systems: the LV-2B DualTip Hand Torch and the LV-A Self-Ignition Hand Torch. Each model provides unique features to suit different welding requirements.

| Feature | LV-2B DualTip Hand Torch | LV-A Self-Ignition Hand Torch |

|---|---|---|

| Flame Temperature | Up to 3600°F | Up to 3600°F |

| Tip Design | Dual tips for larger tubes | Self-ignition tip for quick operation |

| Material | Brass construction for durability | Brass construction for reliability |

| Rotation Capability | 360° spinning capability | 360° spinning capability |

| Gas Compatibility | MAPP and propane gases | MAPP and propane gases |

| Copper Tubing Capacity | Soft soldering up to Φ6”; brazing up to Φ3” | Soft soldering up to Φ4”; brazing up to Φ1¼” |

The LV-2B model is ideal for heavy-duty tasks, such as soldering and brazing larger copper tubes, while the LV-A torch offers quick ignition and efficient operation for smaller-scale applications. Both models ensure consistent performance and reduced gas consumption, making them indispensable tools for refrigeration professionals.

Importance of Ergonomics and Durability

Ergonomics and durability play a crucial role in welding torch selection. Taojun HVAC’s Welding Torch Tools for Refrigeration Systems prioritize user comfort and long-term reliability. Their lightweight design minimizes strain during extended use, while the brass construction ensures durability under demanding conditions.

Research highlights the importance of ergonomic principles in welding tools. A study on welding torch design revealed that lightweight and ribbed handles improve user experience and reduce injury risks. Taojun HVAC’s torches incorporate these principles, offering smooth handles for water-cooled applications and ribbed handles for air-cooled tasks.

Durability is equally vital. Heavy copper construction enhances arc stability, while high-dielectric silicon rubber provides insulation for safe operation. These features ensure Taojun HVAC’s torches withstand rigorous use, delivering consistent results over time.

Tip: Investing in ergonomically designed and durable welding torches not only enhances productivity but also reduces long-term costs associated with tool replacement and worker injuries.

Proper Torch Maintenance

Cleaning and Inspecting Taojun HVAC Torches

Regular cleaning and inspection are essential for maintaining the performance of Taojun HVAC welding torches. Dust, debris, and residue can accumulate on the nozzle and mixing chamber, affecting flame stability and heat output. Professionals should clean the nozzle and torch body daily using a soft brush or compressed air to remove contaminants.

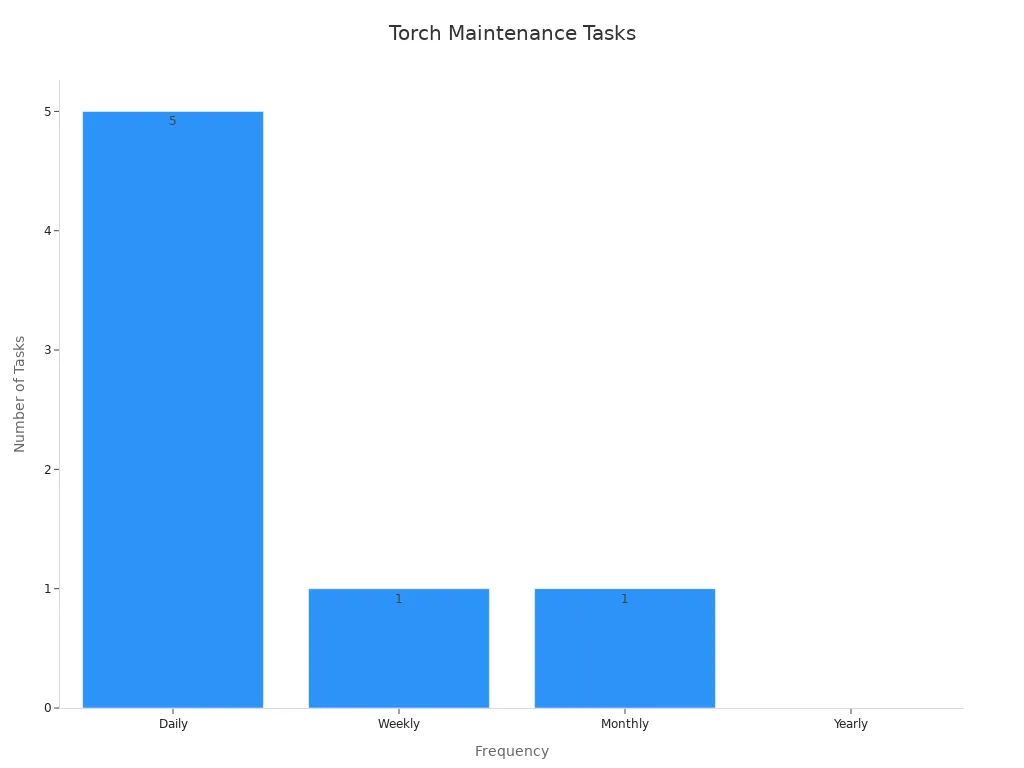

A visual inspection of the torch's alignment and nozzle position should also be conducted daily. This ensures proper gas flow and prevents uneven flame distribution. The table below outlines a recommended maintenance schedule for welding torches:

| Maintenance Task | Daily | Weekly | Monthly | As Necessary / Yearly |

|---|---|---|---|---|

| Visually inspect alignment of nozzle and torch position | X | |||

| Check lubricator to ensure it is working | X | |||

| Check LEDs for reamer and controller communications | X | |||

| Clean station exterior | X | |||

| Check cutter for damage or clogging | X | |||

| Complete clean-up of reamer and sprayer | X | |||

| Check alignment & insertion depth of torches | X |

Tip: Always keep consumables in their original packaging until ready for use. This prevents contamination and ensures optimal performance.

Replacing Components for Longevity

Replacing worn components at regular intervals extends the lifespan of welding torches. valve stems, seats, and O-rings are particularly prone to wear in demanding environments. Professionals should replace valve stems and seats every 3-5 years, while O-rings may require more frequent attention.

Cutting tips should be replaced every 6-12 months to maintain precision and efficiency. The oxygen lever mechanism, often the first to show wear, should be inspected regularly and replaced as needed. The table below provides a detailed replacement schedule for key components:

| Component | Replacement Frequency |

|---|---|

| Valve stems and seats | Every 3-5 years |

| O-rings | More frequently in demanding environments |

| Cutting tips | Every 6-12 months |

| Cutting attachment | 5-10 years |

| Oxygen lever mechanism | First to show wear |

Note: Following a consistent replacement schedule reduces downtime and ensures that Welding Torch Tools for Refrigeration Systems operate at peak efficiency.

Safe Storage Practices

Proper storage safeguards welding torches from damage and contamination. After use, torches should be stored in a clean, dry environment away from direct sunlight and moisture. Consumables, such as nozzles and tips, should remain in their original packaging until needed.

Avoid placing components in open bins, as this can lead to contamination or physical damage. Clean containers with secure lids provide an ideal storage solution. Additionally, ensure that gas cylinders are stored upright and secured to prevent tipping.

Reminder: Safe storage practices not only protect equipment but also enhance workplace safety by minimizing hazards.

Gas and Heat Optimization

Adjusting Gas Flow for Refrigeration Applications

Optimizing gas flow is critical for achieving consistent and efficient welds in refrigeration applications. Proper gas flow ensures a stable flame, which is essential for precise heat transfer and effective joint formation. Professionals should adjust the gas flow rate based on the material type, joint size, and environmental conditions. For instance, higher flow rates may be necessary in outdoor settings to counteract wind interference, while lower rates suffice for indoor tasks.

The angle of the welding torch also influences gas flow efficiency. A study comparing torch angles of 90° and 70° revealed that a 70° angle produced a wider and shallower weld pool, while the 90° angle resulted in a more symmetrical and deeper weld pool. This highlights the importance of maintaining the correct torch angle to optimize gas flow and achieve desired weld characteristics.

Tip: Always refer to the manufacturer’s guidelines for recommended gas flow rates when using Welding Torch Tools for Refrigeration Systems. This ensures optimal performance and reduces gas wastage.

Choosing Between MAPP and Propane Gases

Selecting the appropriate gas type is another crucial aspect of welding torch efficiency. MAPP gas and propane are two popular options, each offering distinct advantages. MAPP gas burns at a higher temperature, making it ideal for tasks requiring rapid heat application, such as brazing copper-to-copper joints. Propane, on the other hand, provides a more controlled flame, which is better suited for delicate operations like soldering aluminum components.

The compatibility of Welding Torch Tools for Refrigeration Systems with both MAPP and propane gases enhances their versatility. Professionals can switch between gases depending on the task requirements, ensuring flexibility and cost-effectiveness.

| Gas Type | Flame Temperature (°F) | Best Applications |

|---|---|---|

| MAPP Gas | Up to 3600 | Brazing copper-to-copper joints |

| Propane | Up to 1800 | Soldering aluminum and smaller joints |

Note: When working with MAPP gas, ensure proper ventilation to prevent the accumulation of fumes, which can pose safety risks.

Managing Heat Settings for Precision

Precise heat management is essential for achieving high-quality welds, especially when working with materials of varying thicknesses. Excessive heat can expand the heat-affected zone (HAZ), leading to coarser grains in the weld’s microstructure and weakening the joint. Conversely, insufficient heat may result in incomplete fusion, compromising the weld’s integrity.

Advanced techniques, such as alternating high and low energy phases, allow for precise heat input control. This method stabilizes the welding process, particularly during vertical-up seams, by enabling effective cooling during low-energy phases. Additionally, maintaining a heat input of approximately 347 J/mm minimizes the HAZ width, refining the microstructure and enhancing the mechanical properties of the weld.

Reminder: Regularly monitor the torch’s heat settings to ensure consistent performance. Adjust the flame type—neutral, carburizing, or oxidizing—based on the material and joint requirements.

Technique Improvement

Controlling Speed and Heat for Copper Tubing

Precise control of speed and heat is essential for welding copper tubing effectively. Excessive speed can lead to incomplete fusion, while slow movement may overheat the material, causing warping or oxidation. Taojun HVAC welding torches, with their adjustable flame settings, allow professionals to maintain optimal heat levels for copper tubing.

Operators should aim for a steady pace, ensuring uniform heat distribution across the joint. A study on arc stability demonstrated that flux bands create a solid-wall constricting effect, reducing unstable arc burning time by 86.85%. This improvement enhances weld quality and minimizes errors. The table below highlights key findings related to arc stability and heating efficiency:

| Finding | Description |

|---|---|

| SWCE Effect | Flux bands reduce unstable arc burning time by 86.85%. |

| Heating Area | Effective heating area increases by at least 5 mm² compared to GMAW. |

| Arc Shape | Flux bands compress the arc shape, improving stability and reducing fluctuations. |

Tip: Maintaining a consistent torch angle and speed ensures a stable weld pool, reducing the risk of defects in copper tubing joints.

Electrode Selection for Different Materials

Choosing the correct electrode is crucial for achieving strong and durable welds across various materials. Copper, brass, and aluminum require electrodes with specific properties to ensure compatibility and optimal performance. For example, tungsten electrodes are ideal for aluminum due to their high melting point and conductivity.

Professionals should consider factors such as material thickness, joint type, and welding position when selecting electrodes. Taojun HVAC welding torches support a range of electrode types, enabling versatility in applications. Proper electrode selection not only improves weld quality but also reduces post-weld cleanup, saving time and resources.

Reminder: Always match the electrode type to the material being welded to prevent contamination and ensure a seamless joint.

Minimizing Waste with Proper Technique

Efficient welding techniques significantly reduce resource waste and environmental impact. Proper management of welding waste enables recycling and reuse, conserving mineral resources and protecting ecosystems. For instance, welding waste can be transformed into valuable materials through physical or chemical processing.

In construction, waste materials from welding can serve as additives for road surfaces and airport pavements, minimizing resource consumption. The table below highlights cost-saving and quality-enhancing outcomes from improved welding techniques:

| Finding | Description |

|---|---|

| Quality | Welded joints maintain mechanical properties comparable to parent fluxes. |

| Cost Reduction | Recycling waste flux dust reduces welding costs and pollution. |

Note: Adopting proper techniques not only enhances weld quality but also contributes to sustainable practices in the industry.

Pre-Weld Preparation

Preparing Materials for Refrigeration Systems

Proper material preparation is essential for achieving high-quality welds in refrigeration systems. Contaminants like oil, dirt, and moisture can weaken welds and compromise joint integrity. Cleaning surfaces thoroughly before welding eliminates these impurities. Professionals often use solvents or wire brushes to remove residues, ensuring a clean base for welding.

Cutting and beveling pipes also play a critical role in pre-weld preparation. Pipes must be cut squarely to create uniform edges, while beveling ensures proper joint geometry for effective welding. Taojun HVAC’s Welding Torch Tools for Refrigeration Systems excel in handling these tasks due to their precision flame control and ergonomic design.

| Preparation Technique | Description |

|---|---|

| Material Cleanliness | Surfaces must be cleaned to remove contaminants like oils and dirt to prevent weak welds. |

| Joint Alignment | Precise alignment is crucial to avoid defects; techniques like tack welding are used. |

| Cutting and Beveling | Pipes should be cut squarely and beveled to ensure proper joint geometry for effective welding. |

Tip: Always inspect materials after cleaning and cutting to ensure they meet the required standards for refrigeration system welding.

Ensuring Proper Fit and Alignment

Achieving proper fit and alignment is critical for preventing defects during welding. Misaligned joints can lead to uneven heat distribution and weak connections. Professionals rely on precision tools and alignment devices to ensure accurate positioning. Tools like the TS27R tool setter from Renishaw and the Z-NANO tool setter from Polon are widely used for this purpose.

- TS27R tool setter from Renishaw

- Z-NANO tool setter from Polon

- TM26D knife alignment device from Meidelong

- NT series laser tool setter from Blum Novotet Gmbh

- NC4 non-contact laser tool setter from Renishaw

These devices help maintain consistent joint alignment, reducing the risk of errors and improving weld quality. Tack welding is another effective technique for securing joints temporarily before final welding.

Reminder: Proper alignment not only enhances weld strength but also minimizes post-weld corrections, saving time and resources.

Checking for Defects in Copper Tubing

Inspecting copper tubing for defects is a vital step in pre-weld preparation. Cracks, dents, and surface irregularities can compromise the weld’s integrity and lead to leaks in refrigeration systems. Professionals use visual inspections and non-destructive testing methods to identify flaws.

Common defects include pinholes, which can result from improper storage or handling. Taojun HVAC’s Welding Torch Tools for Refrigeration Systems provide precise heat control, allowing professionals to repair minor defects effectively. However, tubing with severe damage should be replaced to ensure system reliability.

Note: Regular inspections of copper tubing prevent costly repairs and ensure the longevity of refrigeration systems.

Safety Practices

Using Protective Gear with Taojun HVAC Torches

Welding involves exposure to intense heat, bright light, and potentially hazardous fumes. Proper protective gear is essential to safeguard operators from these risks. Professionals using Taojun HVAC torches should wear flame-resistant clothing, gloves, and safety goggles to shield themselves from sparks and ultraviolet radiation. A welding helmet with a shaded lens further protects the eyes and face from harmful light and flying debris.

Respiratory protection is equally important, especially in confined spaces or poorly ventilated areas. Fume extraction systems or respirators help minimize inhalation of harmful gases. Steel-toed boots and ear protection also enhance safety by preventing injuries from falling objects and prolonged noise exposure.

Tip: Always inspect protective gear for damage before use. Worn-out equipment may compromise safety and increase the risk of injury.

Avoiding Oil and Oxygen Cylinder Contact

Oil and oxygen cylinders must never come into contact due to the risk of combustion. Oxygen accelerates the ignition of flammable substances, making even a small amount of oil or grease hazardous. Operators should handle oxygen cylinders with clean, dry hands and avoid using oily gloves.

The following table highlights key safety recommendations from industry experts:

| Source | Evidence |

|---|---|

| Western Illinois University | Never permit oil, grease, or other readily combustible substances to come in contact with oxygen cylinders, valves, regulators, gauges, or fittings. |

| Industrial Maintenance and Construction/Support Services Safety Manual | Oxygen cylinders and apparatus shall be kept free from oil, grease, and other flammable or explosive substances. Oxygen cylinders or apparatus shall not be handled with oily hands or gloves. Oxygen shall not be used as a substitute for compressed air. |

| Office of Environmental Health and Safety | Never allow oil, greases, and other readily combustible substances to come in contact with oxygen cylinders, valves, regulators, and fittings. |

Reminder: Store oxygen cylinders upright and secure them to prevent tipping. This reduces the risk of accidental leaks or damage.

Following Manufacturer Guidelines

Adhering to manufacturer guidelines ensures safe and efficient operation of welding torches. Taojun HVAC provides detailed instructions for proper usage, maintenance, and storage of their tools. Operators should familiarize themselves with these guidelines to maximize performance and minimize risks.

- Welders must receive training and have access to safety data sheets for hazardous materials.

- Certified welders enhance productivity and safety by adhering to industry standards.

- OSHA safety standards emphasize the use of personal protective equipment (PPE) and adequate ventilation to reduce exposure to hazardous fumes.

- Regular inspection of welding equipment ensures safe operations and prevents malfunctions.

- Managing flammable materials and implementing fire safety measures control potential hazards.

Certification for welders and welding procedures is crucial. It demonstrates compliance with industry standards, which not only improves safety but also enhances operational efficiency and product quality.

Note: Following these guidelines reduces workplace accidents and ensures consistent, high-quality results in welding tasks.

Efficient welding torch usage hinges on several critical strategies. Professionals should:

- Regularly inspect torch components, including nozzles and hoses, to prevent clogs and leaks.

- Select the appropriate gas type and set precise flow rates to optimize performance.

- Train operators on best practices to minimize waste and enhance productivity.

Fume extraction torches, for instance, can reduce fume exposure by up to 50%, improving workplace safety. Taojun HVAC’s advanced welding torches embody these principles, offering precision, durability, and versatility. Adopting these strategies ensures consistent results, cost savings, and a safer work environment.

Tip: Investing in high-quality tools like Taojun HVAC torches elevates efficiency and reliability in every welding task.

FAQ

What makes Taojun HVAC welding torches suitable for refrigeration systems?

Taojun HVAC welding torches deliver high-temperature flames exceeding 2000°C, ensuring precise heat control for copper, brass, and aluminum joints. Their compatibility with MAPP and propane gases, along with ergonomic designs, makes them ideal for refrigeration applications requiring efficiency and reliability.

How often should welding torch components be replaced?

Replace valve stems and seats every 3-5 years, cutting tips every 6-12 months, and O-rings more frequently in demanding environments. Regular inspections ensure timely replacements, extending the torch’s lifespan and maintaining peak performance.

Can Taojun HVAC torches handle both soldering and brazing?

Yes, Taojun HVAC torches support both soldering and brazing. The LV-2B model handles soft soldering up to Φ6” and brazing up to Φ3”, while the LV-A model manages soft soldering up to Φ4” and brazing up to Φ1¼”.

What safety precautions should be followed when using welding torches?

Operators must wear flame-resistant clothing, gloves, and safety goggles. Avoid oil contact with oxygen cylinders, store gas cylinders upright, and follow manufacturer guidelines. Proper ventilation and fume extraction systems minimize exposure to hazardous gases.

How can gas flow optimization improve welding efficiency?

Adjusting gas flow ensures a stable flame, reducing material waste and enhancing weld quality. Taojun HVAC torches allow precise gas flow adjustments, enabling professionals to achieve consistent results across various applications, including refrigeration systems.